Method for synthesizing a small-size high-dispersion intermetallic compound catalyst material and application

A technology of intermetallic compounds and catalysts, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of non-universal synthesis methods, single system, complex process, etc., and achieve the effect of improving catalytic durability and inhibiting easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

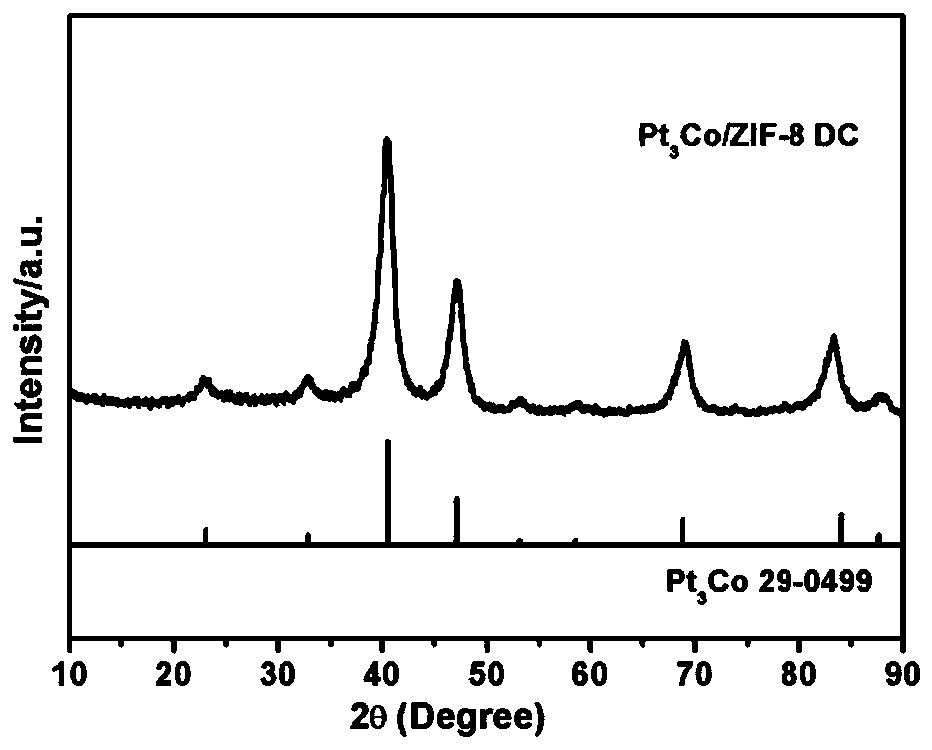

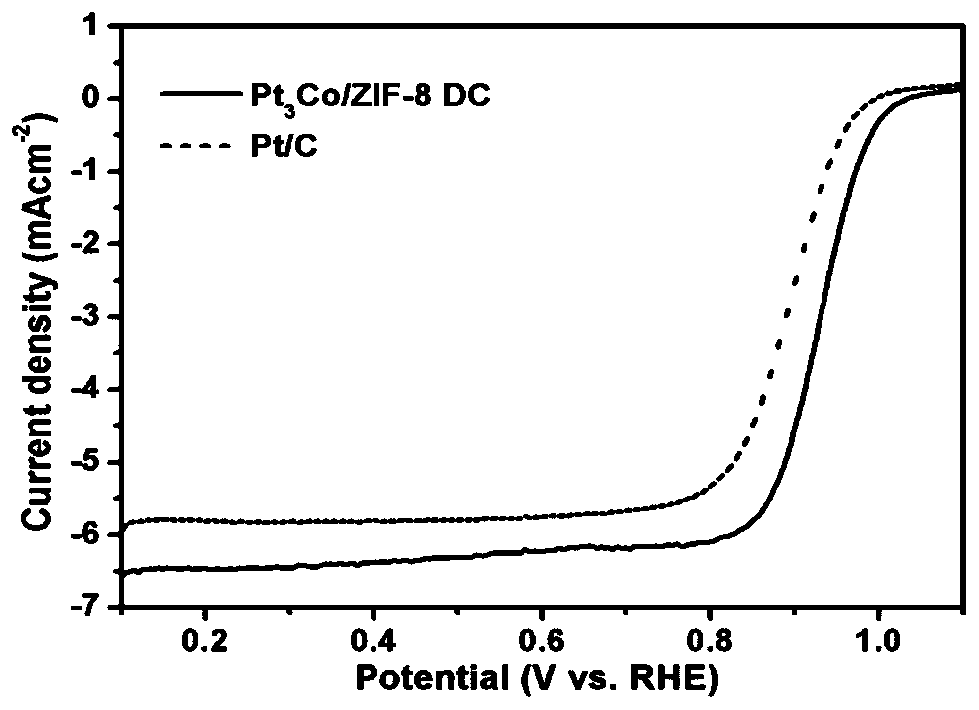

Embodiment 1

[0030] ZIF-8 was pyrolyzed at 950°C for 3 h in an Ar environment, and the resulting ZIF-8-derived carbon was treated with 0.5 M H 2 SO 4 After pickling at 80°C for 10 hours, wash with water until the pH is neutral, dry in vacuum at 80°C, and grind. Dissolve chloroplatinic acid and cobalt chloride in deionized water, and ultrasonically mix to form a uniform metal precursor solution. The concentrations of chloroplatinic acid and cobalt chloride are 0.256 mol / L and 0.086 mol / L, respectively. Take 100 ul metal precursor solution and drop evenly into 20 mg treated ZIF-8 derived carbon, sonicate for 1 h, and then freeze-dry. Dry the product in 8% H 2 / Ar atmosphere at 750 ℃ for 2h. Get fuel cell catalyst Pt 3 Co / ZIF-8 DC.

Embodiment 2

[0032] UIO-66 was pyrolyzed at 950 °C for 3 h in an Ar environment, and the obtained UIO-66 derived carbon was treated with an aqueous solution of HF (HF and H 2 O volume ratio is 1:1), after acid washing at 60 °C for 10 h, washing with water until the pH is neutral, vacuum drying at 80 °C, and grinding. Dissolve chloroplatinic acid and cobalt chloride in deionized water, and ultrasonically mix to form a uniform metal precursor solution. The concentrations of chloroplatinic acid and cobalt chloride are 0.256 mol / L and 0.086 mol / L, respectively. Take 100ul of the metal precursor solution and drop evenly into 20 mg of treated UIO-66 derived carbon, sonicate for 1 h, and then freeze-dry. Dry the product in 8% H 2 / Ar atmosphere at 750 ℃ for 2h. Get fuel cell catalyst Pt 3 Co / UIO-66DC.

Embodiment 3

[0034] ZIF-8 was pyrolyzed at 950°C for 3 h in an Ar environment, and the resulting ZIF-8-derived carbon was treated with 0.5 M H 2 SO 4 After pickling at 80°C for 10 hours, wash with water until the pH is neutral, dry in vacuum at 80°C, and grind. Dissolve chloroplatinic acid and ferric chloride in deionized water, and ultrasonically mix to form a uniform metal precursor solution. The concentrations of chloroplatinic acid and ferric chloride are 0.256 mol / L and 0.086 mol / L, respectively. Take 100 ul metal precursor solution and drop evenly into 20 mg treated ZIF-8 derived carbon, sonicate for 1 h, and then freeze-dry. Dry the product in 8% H 2 / Ar atmosphere at 750 ℃ for 2h. Get fuel cell catalyst Pt 3 Fe / ZIF-8 DC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com