High-pressure reaction system, and efficient energy recovery feeding and discharging process

A technology of high-pressure reaction and high-pressure reactor, which is applied in the field of high-pressure reaction system and high-efficiency energy recovery material inlet and outlet process, which can solve the problems of valve wear, short service life, and loss of unloading energy, so as to reduce power consumption and avoid high pressure difference Valve wear and the effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

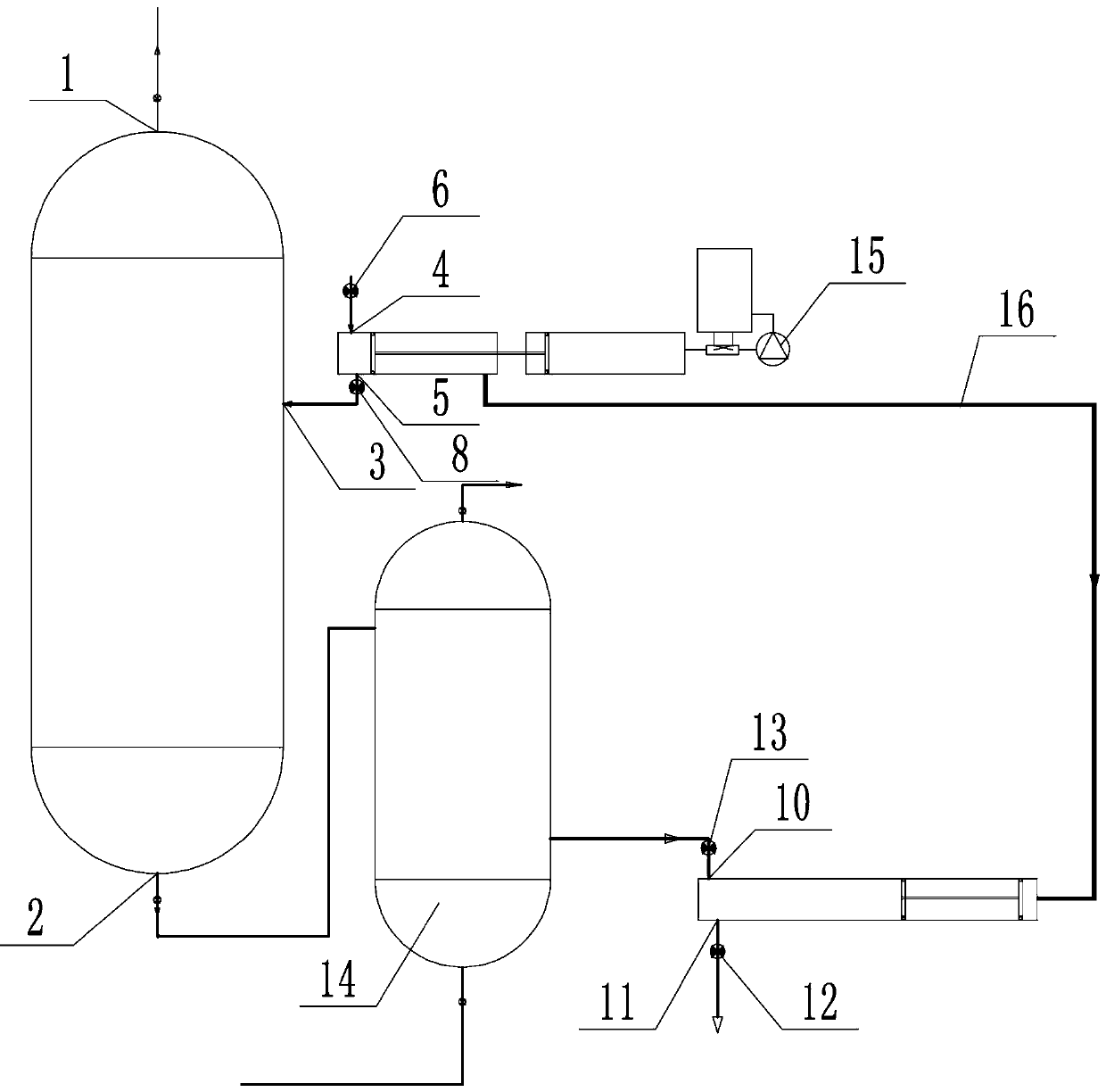

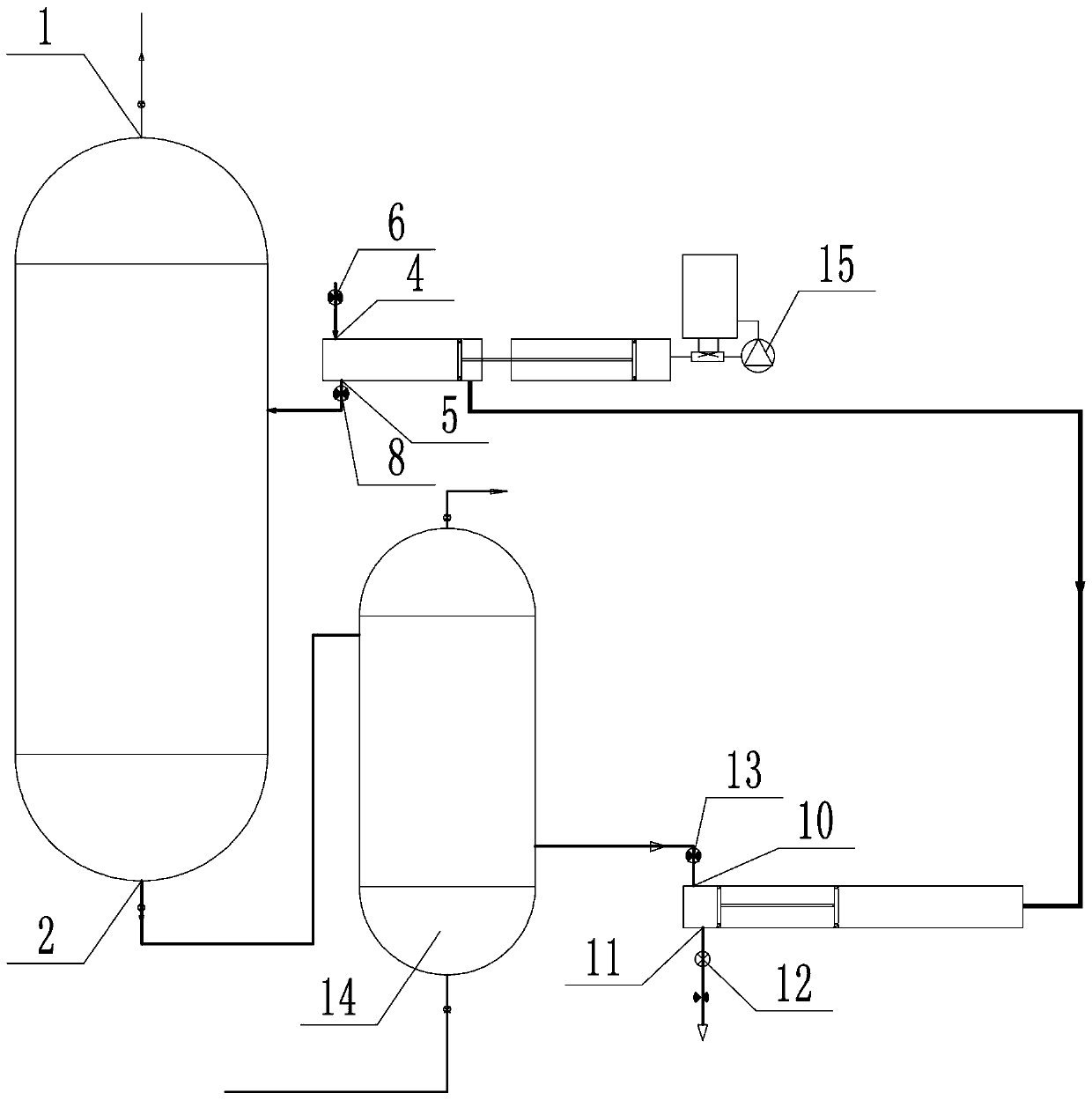

[0036] like Figure 1-2 Shown, the present invention comprises:

[0037] A high-pressure reactor is provided with a first feed port 3 and a liquid phase discharge port 2; the first feed port 3 is located on the side wall of the high-pressure reactor; the optional parameters of the high-pressure reactor are 110-500atm, 200° C- 500°C high pressure reactor. The first feeding port 3 is used to transport the materials in the feeding cylinder into the high pressure reactor.

[0038] Feed cylinder, it comprises the feed cylinder inlet 4 that is provided with first valve 6, the feed cylinder outlet 5 that is connected with described first feed inlet 3, described first feed inlet 3 and inlet A second valve 8 is arranged between the material outlets 5 of the material cylinder; the first valve 6 is used to control the opening and closing of the material inlet 4 of the material cylinder, and the second valve 8 is used to control the opening and closing of the first material inlet 5 .

...

Embodiment 2

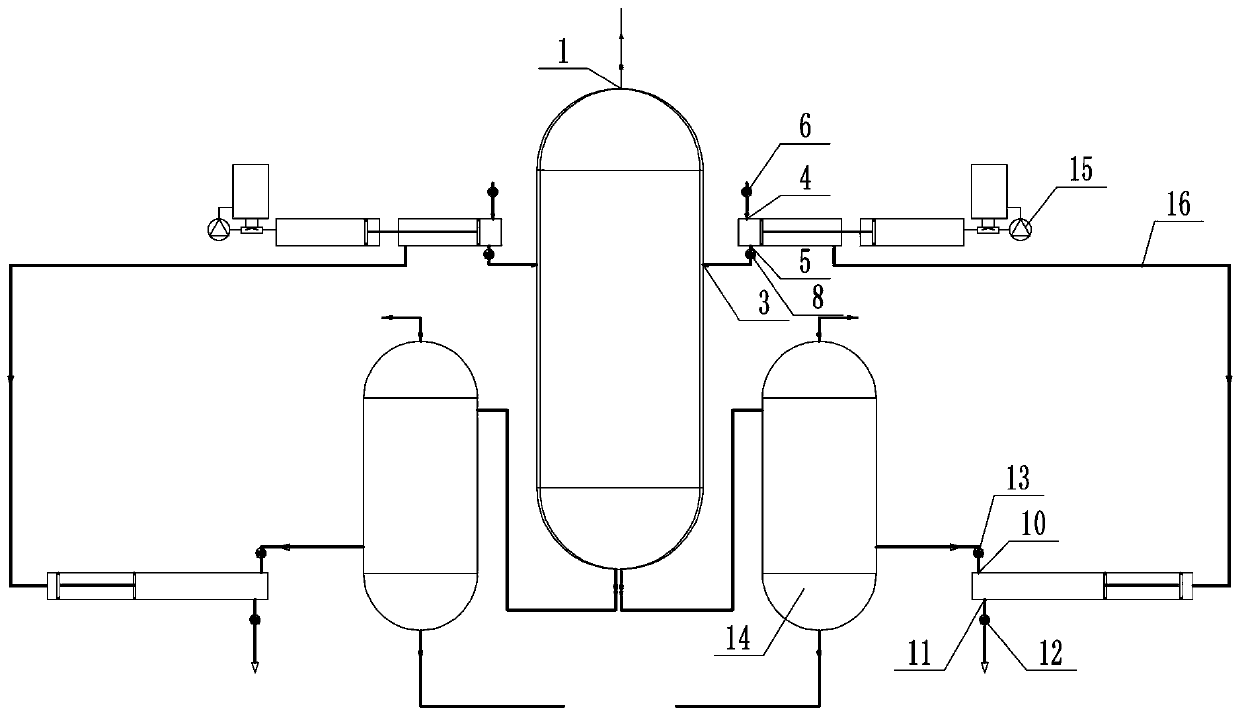

[0066] like Figure 1-3 As shown, the difference between the present embodiment and the high-pressure reaction system of Embodiment 1 is that the quantity of the feed cylinder, the discharge cylinder and the hydraulic pump 15 in the present embodiment is two, one feed cylinder, one discharge cylinder and An oil pressure pump 15 connected with the feeding cylinder is a group of feeding and discharging devices, and a high-pressure reactor is respectively connected with two groups of feeding and discharging devices. As shown in the figure, in this embodiment, two sets of feeding and discharging devices are respectively located on the left and right sides of the high pressure reactor.

[0067] The present invention also provides a high-efficiency energy recovery feed-in and discharge process based on the high-pressure reaction system of the present invention, which includes the following steps,

[0068] The two groups of feeding and discharging devices are respectively the first ...

Embodiment 3

[0076] The difference between this embodiment and Embodiment 2 is that in this embodiment, the gas phase outlet 1 of the high-pressure reactor is connected to the second heat exchanger, and the second heat exchanger is connected to the equipment. The second heat exchanger recovers the energy of the gas phase outlet 1 and provides thermal energy and kinetic energy for the connected equipment. Thus, this embodiment further makes full use of system energy and improves the energy utilization rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com