Production process for preparing activated carbon from sludge

A technology for preparing activated carbon and production process, which is applied in the direction of carbon compounds, inorganic chemistry, chemical instruments and methods, etc. It can solve the problems of water and soil pollution, land occupation, large investment, etc., and achieve uniform activation, lower energy consumption costs, and system energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below.

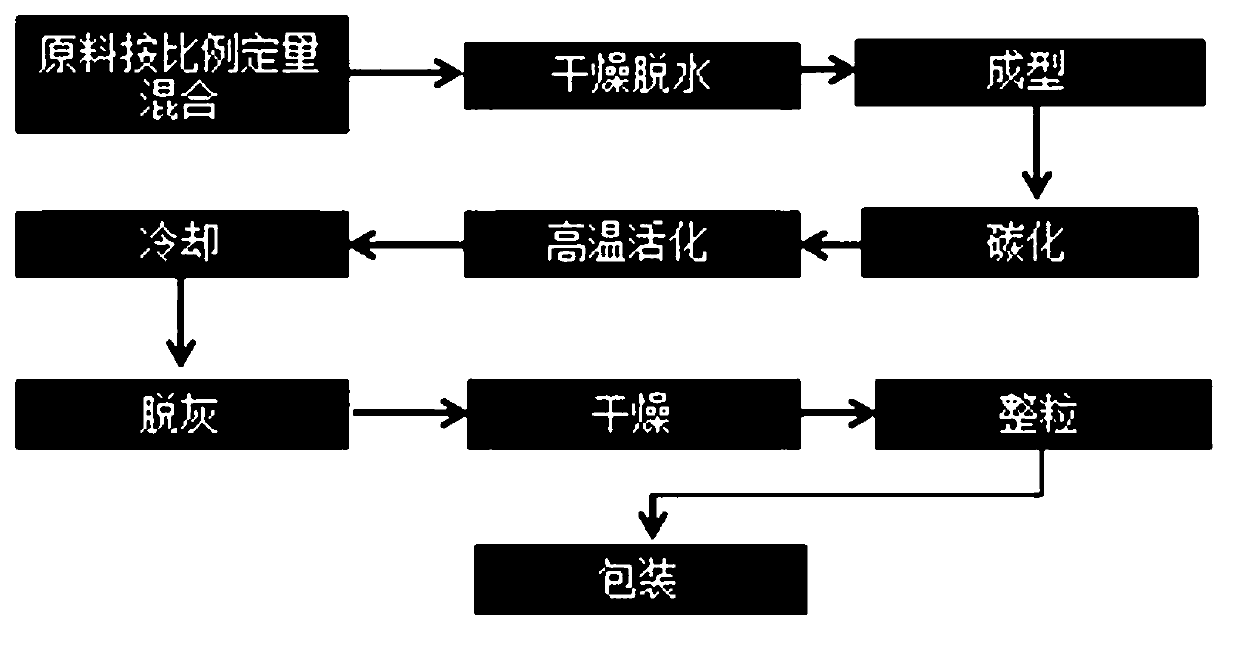

[0024] 1. The production process of preparing activated carbon from sludge, including the following steps:

[0025] (1) Preparation process of raw materials

[0026] The first is the quantitative feeding of urban sludge, carburant, and surface strength additives for the production of raw materials, then the mixing and drying and dehydration of these three materials, and finally the granulation of the materials after drying and dehydration to complete the raw material preparation process.

[0027] Quantitative feeding of municipal sludge, carburizer, and surface strength additives. Sludge quantitative feeding adopts pumping and screw airtight conveying methods to ensure the accuracy of feeding and prevent sludge odor from escaping. The quantitative feeding of carburizer and surface strength additive adopts the production car loading and quantitative belt transportation to realize the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com