Integrated technology for treating wheat straw wastewater

A waste water and technology technology, applied in the direction of sedimentation treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of environmental secondary pollution, environmental hazards such as organic chlorides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

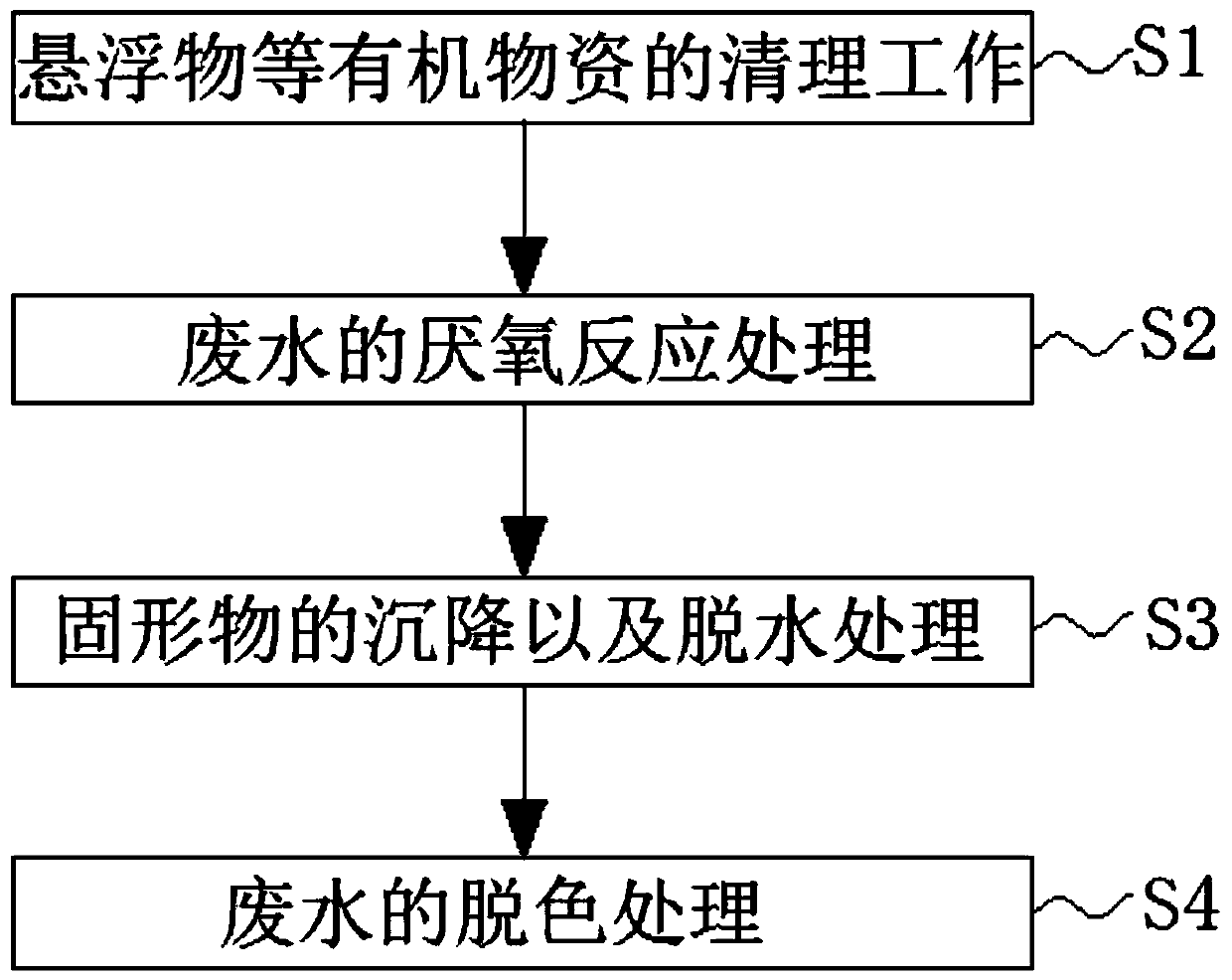

[0023] S1. Cleaning of suspended solids and other organic substances: discharge the wastewater generated after the chlor-alkali cleaning pulping process to the adjustment tank, buffer in the adjustment tank, set a suitable buffer time, and adjust the pH value of the wastewater in the adjustment tank , and carry out pre-aeration work. After this period of buffering, the wastewater is transported into the high-speed screw separator at a speed of 300r / min. After most of the suspended solids in the wastewater and organic substances in the suspended solid state are eliminated The high-speed spiral separator can only be turned off after it has been completely cleared;

[0024] S2. Anaerobic reaction treatment of wastewater: transport the wastewater after removing suspended solids in S1 to the anaerobic reactor, react in the anaerobic reactor for 3 hours, and remove most of the organic matter under the action of anaerobic microorganisms. The anaerobic reactor is stopped after the mat...

Embodiment 2

[0028] S1. Cleaning of suspended solids and other organic substances: discharge the wastewater generated after the chlor-alkali cleaning pulping process to the adjustment tank, buffer in the adjustment tank, set a suitable buffer time, and adjust the pH value of the wastewater in the adjustment tank , and carry out pre-aeration work. After this period of buffering, the wastewater is transported into the high-speed screw separator at a speed of 400r / min. After most of the suspended solids in the wastewater and organic substances in the suspended solid state are eliminated The high-speed spiral separator can only be turned off after it has been completely cleared;

[0029]S2. Anaerobic reaction treatment of wastewater: transport the wastewater after removing suspended solids in S1 to the anaerobic reactor, react in the anaerobic reactor for 4 hours, and remove most of the organic matter under the action of anaerobic microorganisms. The anaerobic reactor is stopped after the mate...

Embodiment 3

[0033] S1. Cleaning of suspended solids and other organic substances: discharge the wastewater generated after the chlor-alkali cleaning pulping process to the adjustment tank, buffer in the adjustment tank, set a suitable buffer time, and adjust the pH value of the wastewater in the adjustment tank , and carry out pre-aeration work. After this period of buffering, the wastewater is transported into the high-speed screw separator at a speed of 500r / min. After most of the suspended solids in the wastewater and the organic substances in the suspended solid state are eliminated The high-speed spiral separator can only be turned off after it has been completely cleared;

[0034] S2. Anaerobic reaction treatment of wastewater: transport the wastewater after removing suspended solids in S1 to the anaerobic reactor, react in the anaerobic reactor for 5 hours, and remove most of the organic matter under the action of anaerobic microorganisms. The anaerobic reactor is stopped after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com