A kind of carbon fiber reinforced carbon-hafnium tantalum carbon solid solution composite material and preparation method thereof

A composite material and carbon fiber prefabricated technology, applied in the field of C/C composite material preparation, can solve the problems of low content of antioxidant components, poor thermal matching, uneven distribution, etc., to achieve enhanced antioxidant performance, excellent oxidation resistance, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

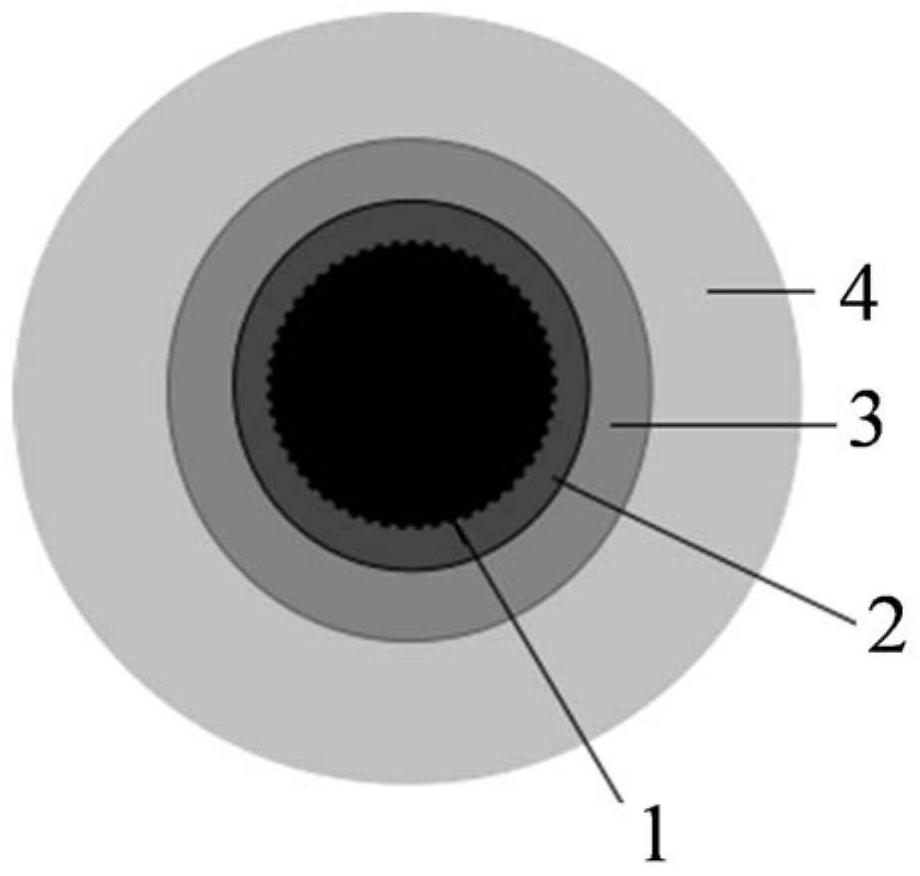

[0032] The present invention provides a C in the first aspect f / C-Ta x The preparation method of HfC composite material, described method comprises the steps:

[0033] (1) A carbon fiber preform deposited with a pyrolytic carbon interface layer was impregnated with phenolic resin (C f prefabricated body), and then the impregnated carbon fiber prefabricated body is sequentially subjected to the steps of solidification and pyrolysis;

[0034] (2) Repeat step (1) 2 to 5 times (eg 2, 3, 4 or 5 times) to obtain a composite material containing a C matrix (carbon matrix);

[0035] (3) impregnating the composite material containing the C matrix with the hafnium tantalum carbon precursor solution, and then performing the steps of curing and pyrolysis of the impregnated composite material containing the C matrix sequentially; the hafnium tantalum carbon precursor solution The molar ratio is 1:(2~4):(3~5) (eg 1:2:3, 1:2:4, 1:2:5, 1:3:3, 1:3:4, 1 :3:5, 1:4:3, 1:4:4 or 1:4:5) hafnium ...

Embodiment approach

[0050] According to some specific embodiments, the C f / C-Ta x The preparation method of HfC composite material comprises the following steps:

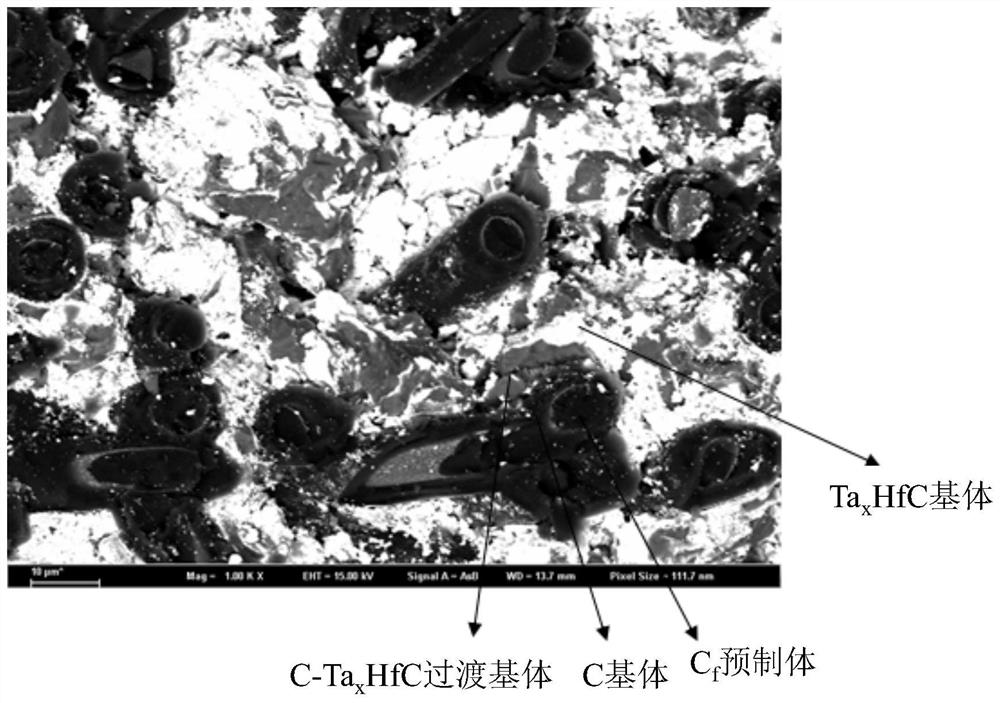

[0051] ①Preparation of C matrix: Completely impregnate the carbon fiber prefabricated body with the pyrolytic carbon interface layer in the phenolic resin, immerse for 1 to 3 hours in an environment with a vacuum degree of 5 to 100kPa, and then immerse it at 150 to 220°C under a pressure of 3 to 3 Cross-linking and curing in a 10MPa pressure tank for 5-10 hours; the cured preform is placed in a cracking furnace, and cracked at a high temperature of 700-1000°C for 2-5 hours. Repeat the above process 2 to 5 times, so that the density of the composite material containing the C matrix is 1.0 to 1.4 g / cm 3 .

[0052] ②C-Ta x Preparation of the HfC transition matrix: The composite material containing the C matrix in step ① is completely immersed in the hafnium-tantalum-carbon precursor solution, immersed for 1-3 hours in an environmen...

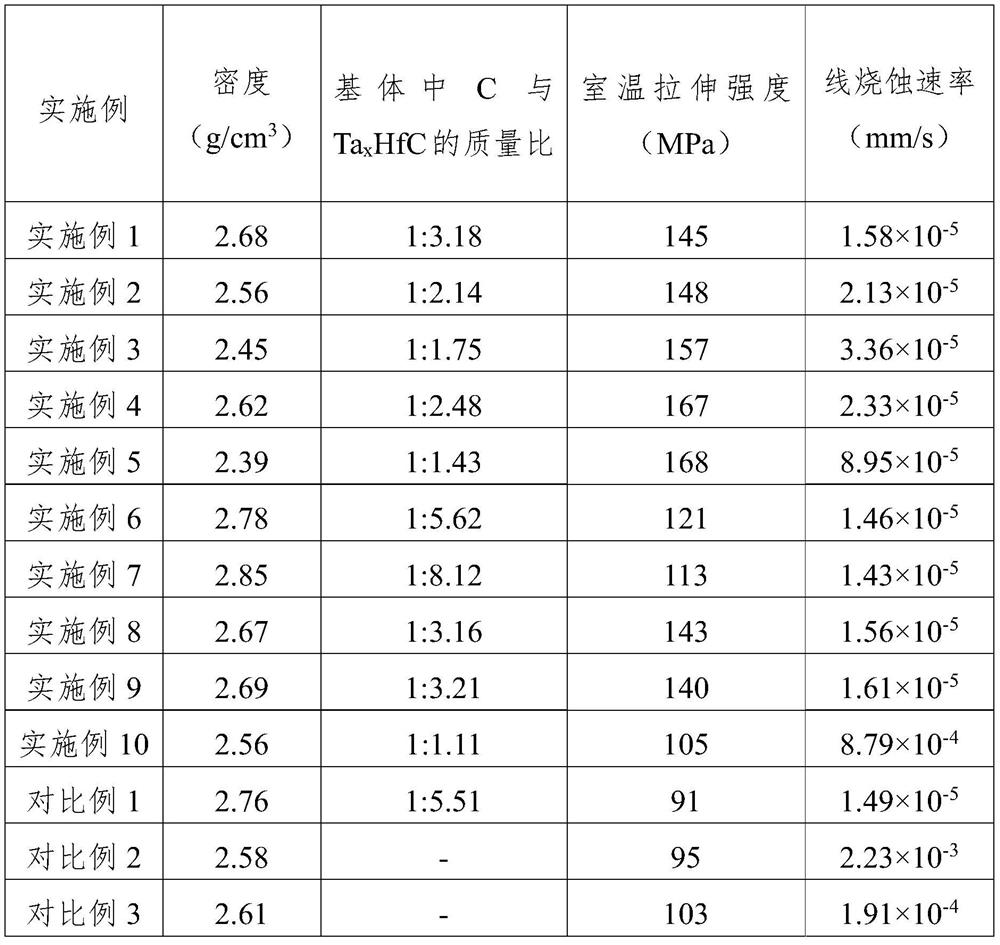

Embodiment 1

[0057] a C f / C-Ta x The preparation method of HfC composite material, its concrete steps are:

[0058] ①Preparation of C matrix: The carbon fiber prefabricated body deposited with the pyrolytic carbon interface layer is completely impregnated in phenolic resin, impregnated for 3 hours in an environment with a vacuum degree of 10kPa, and then cross-linked and cured in a pressure tank at 200°C and a pressure of 5MPa 5 hours; the cured preform is placed in a cracking furnace and cracked at a high temperature of 900° C. for 3 hours. Repeat the above process twice, so that the density of the composite material containing the C matrix is 1.1g / cm 3 .

[0059] ②C-Ta x Preparation of HfC transition matrix: In terms of molar parts, 1 part of hafnium-tantalum precursor, 2 parts of phenolic resin and 3 parts of alcohol solvent (ethylene glycol) were prepared into a hafnium-tantalum-carbon precursor solution. Completely immerse the composite material containing the C matrix in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com