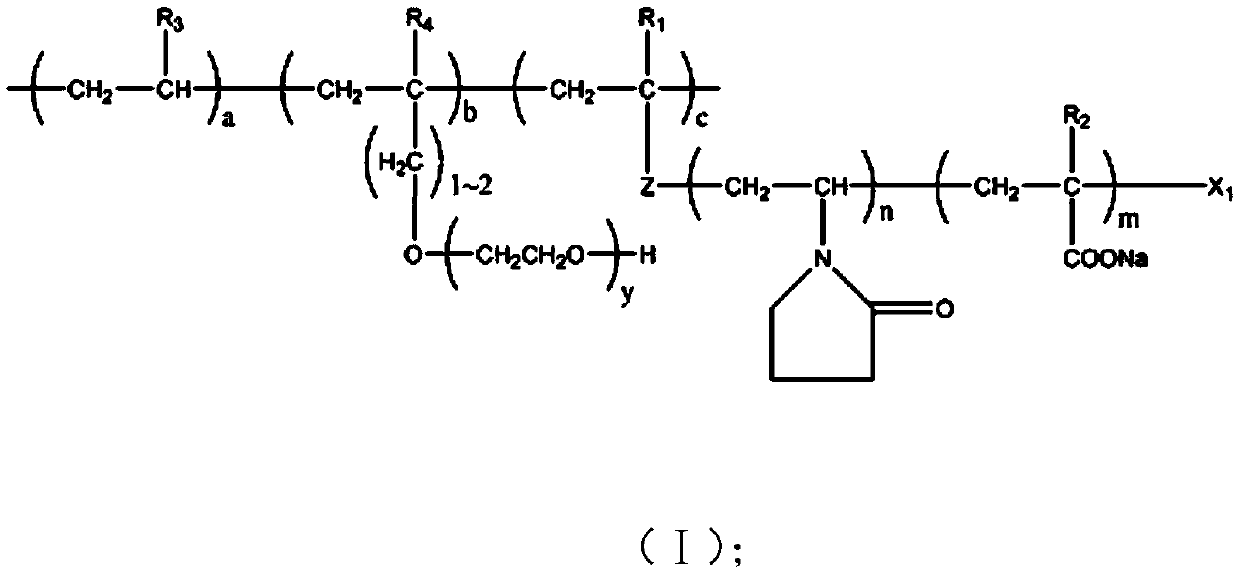

Multifunctional polycarboxylate water-reducer containing gradient polymer side chain and preparation method of multifunctional polycarboxylate water-reducer

A gradient polymer and gradient copolymer technology, applied in the field of polycarboxylate superplasticizer, can solve the problems of poor adaptability and soil sensitivity of cement and fly ash, achieve good suspension, delay cement hydration speed, reduce shrinkage and cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

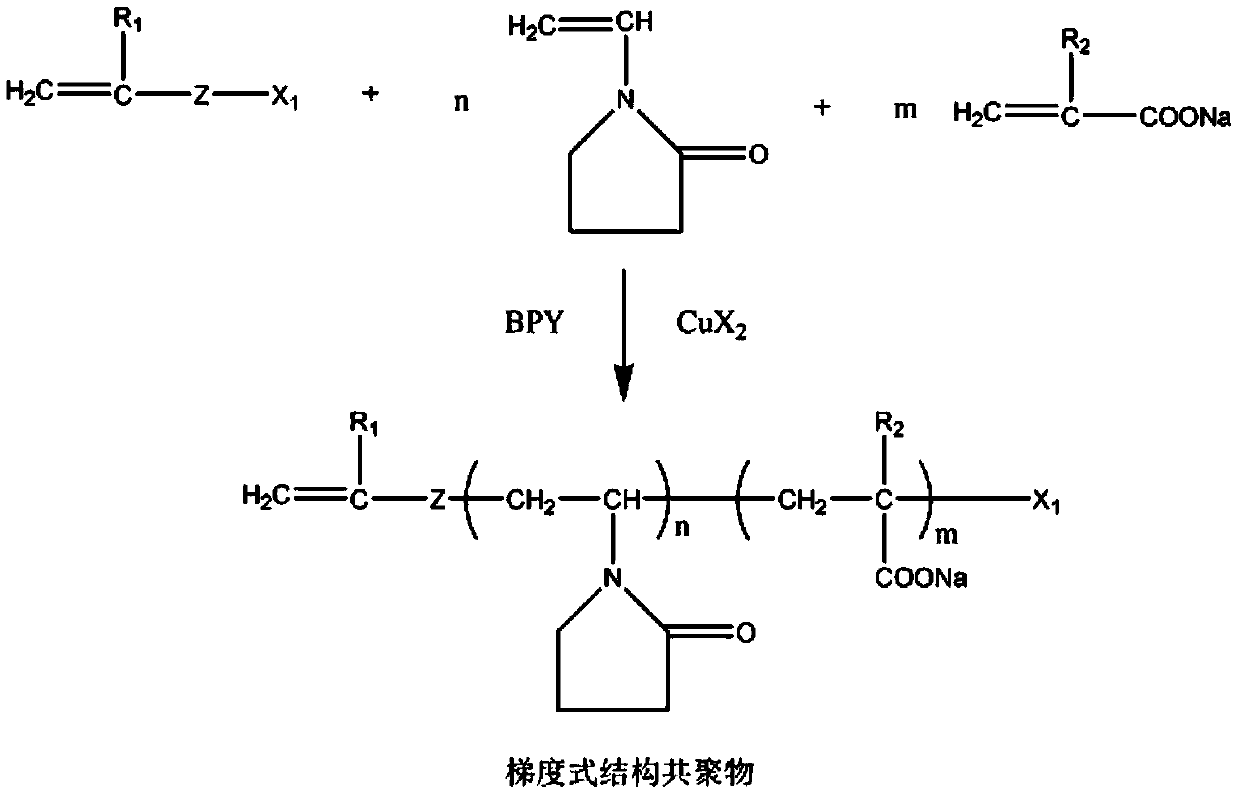

Method used

Image

Examples

Embodiment 1

[0033] An embodiment of the polycarboxylate water reducer containing gradient polymer side chains in the present invention, the polycarboxylate water reducer containing gradient polymer side chains in this embodiment is prepared by the following method:

[0034] (1) Add monomer vinylpyrrolidone, water, and sodium acrylate into a four-necked round-bottomed flask. Under nitrogen protection, add CuCl and 2,2'-bipyridine (BPY), heat up to 40°C, and stir for 40 minutes. The reactant is fully dissolved, and the initiator 3-bromopropene is added to initiate the polymerization. After 5 hours, the nitrogen gas is stopped to terminate the reaction, and an aqueous solution of polyvinylpyrrolidone and polyacrylic acid gradient copolymer active macromonomer is obtained; wherein, the reactant The molar ratio is: vinylpyrrolidone: sodium acrylate: 3-bromopropene: CuCl: BPY=50:50:1.0:0.15:0.15;

[0035] (2) In the four-necked flask in step (1), add PEG active macromonomer, heat up to 35°C, st...

Embodiment 2

[0038] An embodiment of the polycarboxylate water reducer containing gradient polymer side chains in the present invention, the polycarboxylate water reducer with gradient polymer side chains in this embodiment is prepared by the following method:

[0039] (1) Add monomer vinylpyrrolidone, water, and sodium acrylate into a four-necked round-bottomed flask. Under nitrogen protection, add CuBr and 2,2'-bipyridine (BPY), heat up to 85°C, and stir for 20 minutes. The reactant is fully dissolved, and the initiator 3-chloropropene is added to initiate polymerization. After 10 hours, the nitrogen gas is stopped to terminate the reaction, and an aqueous solution of polyvinylpyrrolidone and polyacrylic acid gradient copolymer active macromonomer is obtained; wherein, the reactant The molar ratio is: vinylpyrrolidone: sodium acrylate: 3-bromopropene: CuBr: BPY=80:50:1.6:0.3:0.3;

[0040] (2) In the four-necked flask in step (1), add PEG active macromonomer, heat up to 60°C, stir to fully ...

Embodiment 3

[0043] An embodiment of the multifunctional polycarboxylate water reducer containing gradient polymer side chains of the present invention, the multifunctional polycarboxylate water reducer containing gradient polymer side chains described in this example is prepared by the following method Income:

[0044] (1) Add monomer vinylpyrrolidone, water, and sodium acrylate into a four-necked round-bottomed flask. Under nitrogen protection, add CuCl and 2,2'-bipyridine (BPY), heat up to 65°C, and stir for 30 minutes. The reactant is fully dissolved, and the initiator 4-bromo-n-butene is added to initiate the polymerization. After 7 hours, the nitrogen gas is stopped to terminate the reaction, and an aqueous solution of polyvinylpyrrolidone and polyacrylic acid gradient copolymer active macromonomer is obtained; wherein, The molar ratio of the reactants is: vinylpyrrolidone: sodium acrylate: 3-bromopropene: CuCl: BPY=65:70:1.4:0.2:0.25;

[0045] (2) In the four-necked flask in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com