UV optical adhesive and uses as pathological section sealing adhesive

A technology for optical adhesives and uses, which is applied in the direction of material analysis, adhesives, and scientific instruments through optical means. It can solve the problems of shortening the drying time and achieve the effects of improving efficiency, good application prospects, and increasing drying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, the preparation of UV optical glue of the present invention

[0031] In the UV optical adhesive of the present invention, polyethylene glycol methyl ether acrylate is used as a prepolymer, vinyl acetate is used as a reactive diluent, and 2-hydroxyl-2-methyl-1-phenyl-1-acetone is used as photoinitiator.

[0032] The specific preparation method is as follows: according to the formula shown in Table 1, measure each raw material respectively, mix them evenly, and obtain the product.

[0033] Table 1. UV Optical Adhesive Formulation (mL)

[0034]

[0035]

[0036] The beneficial effects of the present invention are demonstrated through experimental examples below.

experiment example 1

[0037] Experimental example 1. Drying time test of UV optical glue

[0038] 1. Experimental method

[0039] (1) Test materials: the UV optical adhesive prepared in Example 1; neutral resin mounting agent (Thermo ClearVue mounting agent; product number 4212; batch number 406379);

[0040] (2) Slicing production:

[0041] a. Grouping: Take 10 HE-stained pathological slides that have been stained, divide them into 2 groups (neutral resin group, UV optical glue group), and mark them;

[0042] b. Mounting: According to the section grouping, drop the same volume of neutral resin mounting agent and the UV optical glue prepared in Example 1 on the slide, then cover with a cover glass, and place carefully after sealing drying plate;

[0043] (3) Drying: After the neutral resin group is sealed, put it in a ventilated place at room temperature to dry and cure naturally. After the UV optical glue group is sealed, put it into an ultraviolet light irradiation device (DEYIWISE UV glue cur...

experiment example 2

[0050] Experimental example 2. Test of the sealing effect of UV optical glue

[0051] 1. Experimental method

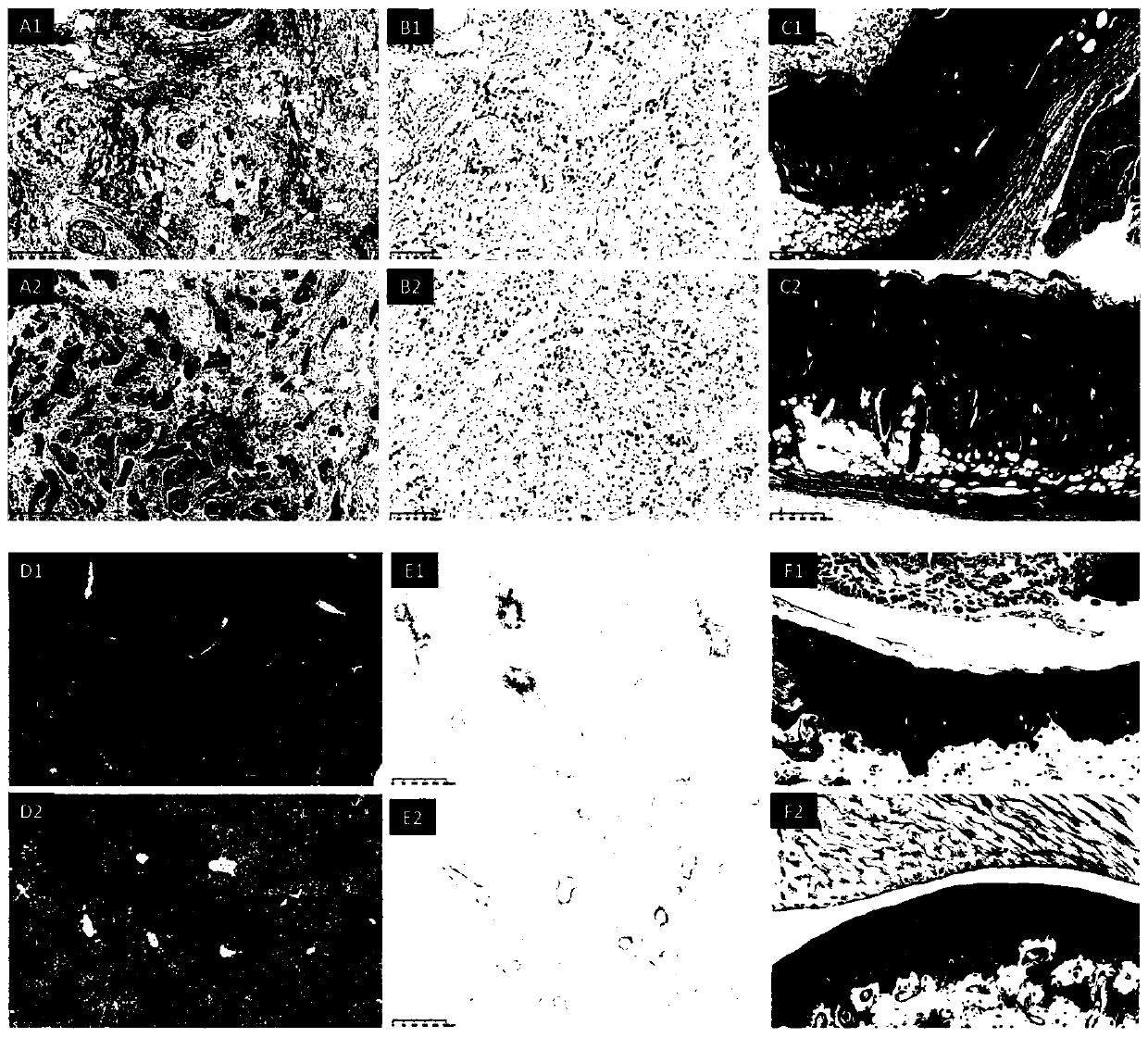

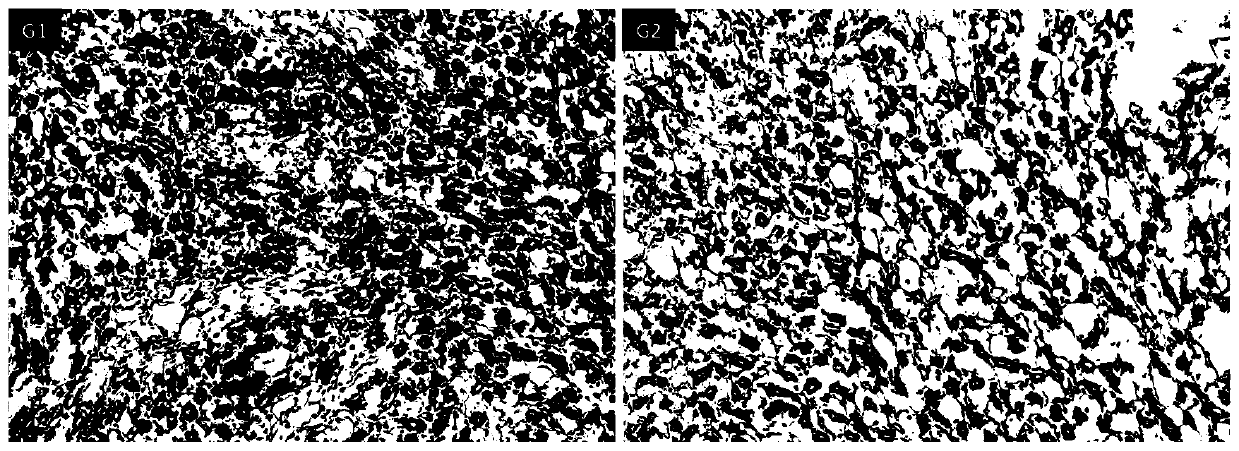

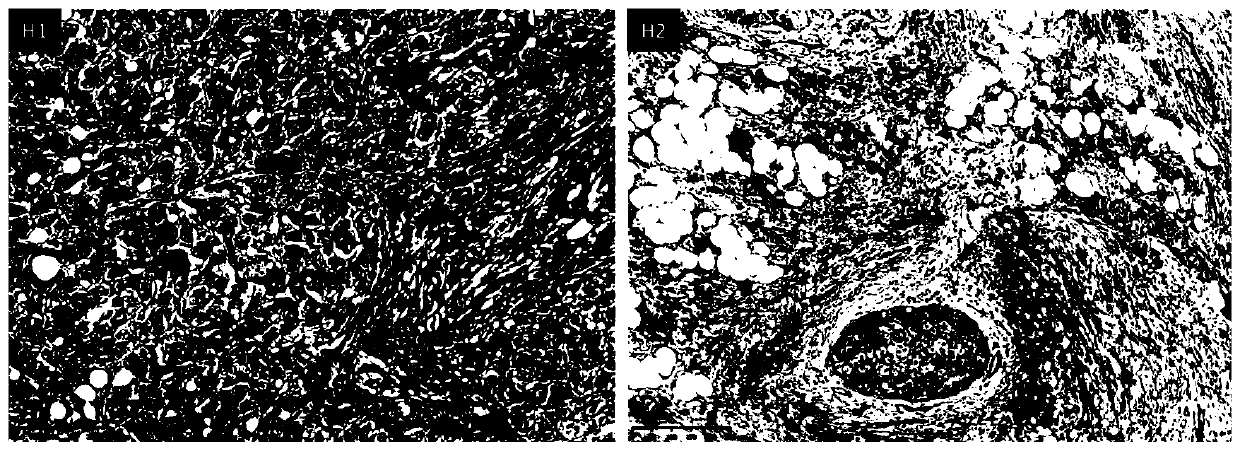

[0052] (1) Use the UV optical glue (sample 42) and neutral resin mounting agent prepared in Example 1 to mount the following stained paraffin pathological sections: HE staining, Masson staining, glycogen staining, formazan Aniline blue staining, Sirius red staining, and immunohistochemical staining, and then collect images to observe the effect of sectioning after mounting.

[0053] (2) UV optical glue (sample 42) and neutral resin mounting agent prepared in Example 1 are used to mount the following frozen pathological sections that have been stained: HE staining, then collect images, observe after mounting slice effect.

[0054](3) After sealing the HE-stained pathological sections with the UV optical glue (sample 42) prepared in Example 1, the images were collected; stored at room temperature under dry and ventilated conditions for 2 years, and the images were col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com