Method and device for preparing superfine atomic force microscope metal probe

A technology of atomic force microscope and metal probe, which is applied in the direction of measuring device, scanning probe technology, scanning probe microscopy, etc., can solve the problems of large radius of curvature of the tip, easy to break, low reflectivity, etc., and achieve stability and Good electrical conductivity, not easy to fall off or wear, high preparation success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

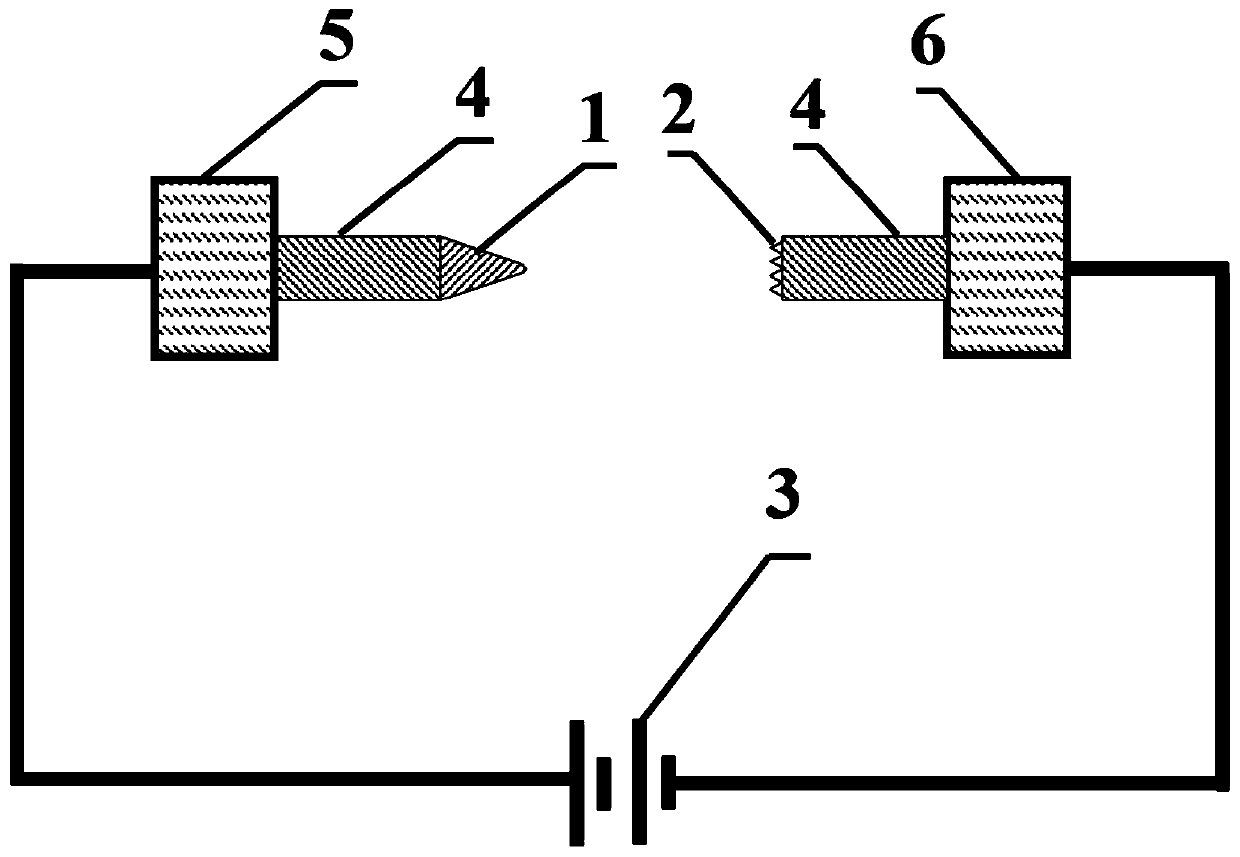

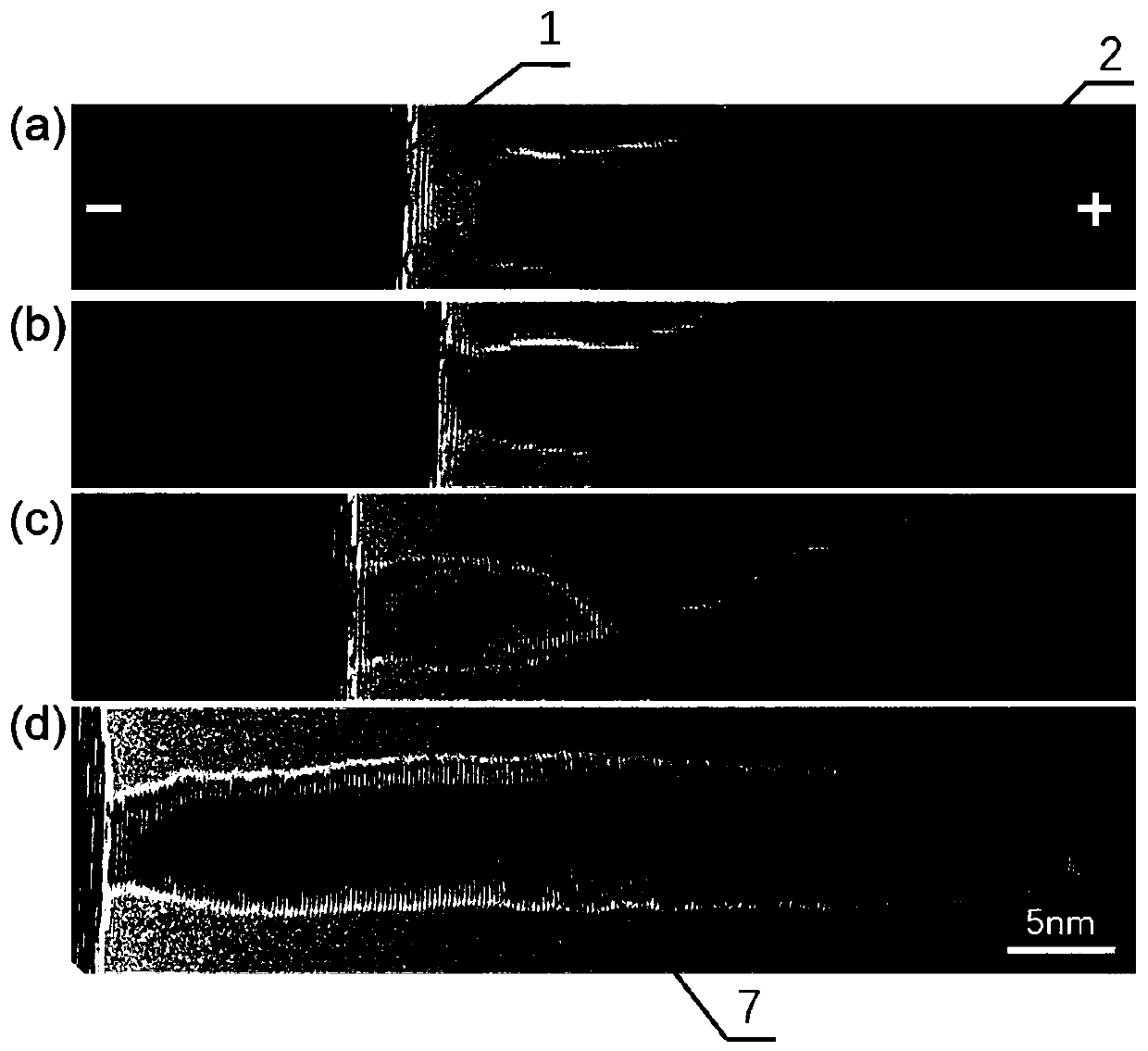

[0058] 4) Preparation of metal probes for atomic force microscopy: A certain amount of voltage is applied to both ends of the electrical-mechanical mono-tilt sample rod. - The movable end of the mechanical mono-tilt sample rod moves the movable end of the metal needle tip 1, so that the gap between the metal needle tip 1 and the metal fracture end 2 is close to about 2nm, and the close parts of both ends are connected to each other under the action of electromigration, A single crystal metal nanowire is formed; and then the movable end is slowly moved backward at a uniform speed, and finally the two ends are separated to obtain a single ultra-fine atomic force microscope metal probe 7 with a certain length;

[0059] 5) Repeat the above step 4) repeatedly to make the atomic force microscope metal probe grow stably along the axial direction, and obtain an atomic force microscope metal probe with an ideal length and shape through multiple adjustments, that is, an atomic force micr...

Embodiment 1

[0067] Such as image 3 and Figure 5 shown.

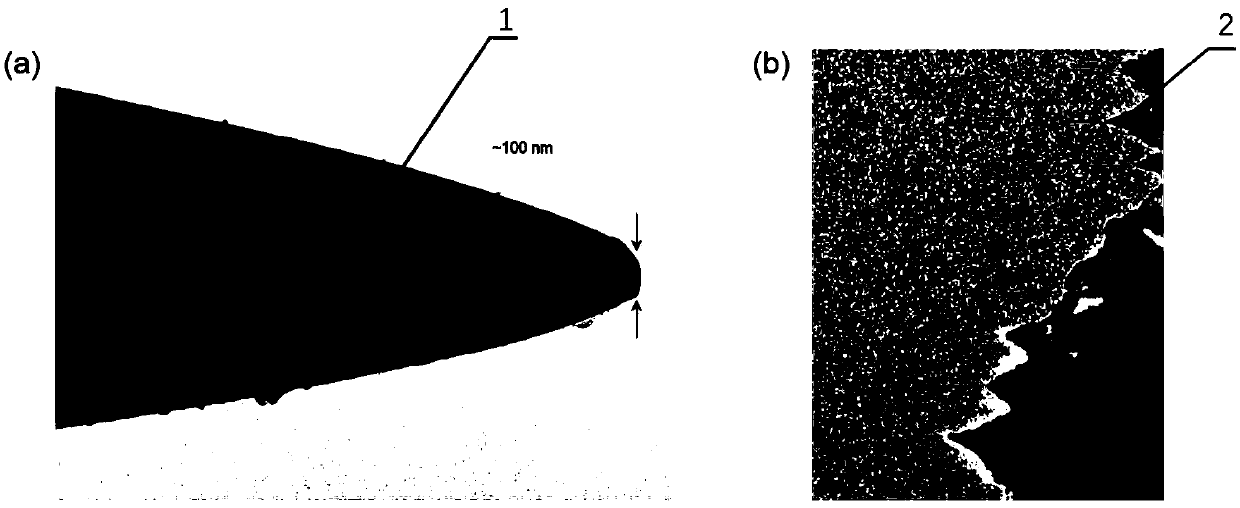

[0068] (1) Physical shearing to prepare the metal fracture end 2

[0069] Sonicate a tungsten metal wire with a diameter of 0.25 mm in ethanol solution for 10 minutes, flatten it with a vise, and cut it with scissors. At this time, there will be a large number of nanometer-sized small protrusions on the front end of the wire to form a nanoscale rough surface, that is, At the metal fracture end 2, a large number of small protrusions of nanometer size exist at the front end, with different shapes and orientations. Fix the root of the metal fracture end 2 to the fixed end, and the flattened and cut end of the metal fracture end 2 faces the movable end.

[0070] (2) Electrochemical corrosion of tungsten wire

[0071] The specific implementation adopts tungsten metal wire, which is ultrasonically cleaned in ethanol solution before use to remove surface dirt. Configure 1mol / L sodium hydroxide solution, combined with an electrochemi...

Embodiment 2

[0081] The difference from Example 1 is that the growth direction is different, the metal needle tip 1 is connected to the negative pole of the power supply 3 , the metal fracture end 2 is connected to the positive pole of the power supply 3 , and the others are the same as in Example 1. The implementation process is shown as Figure 4 and Figure 6 As shown, the metal atom 8 is to the right.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com