Chromium-contaminated land remediation method

A remediation method and technology for chromium pollution, applied in the field of bioremediation of chromium-contaminated soil, can solve the problems of high mutagenicity and toxicity, high cost, mutagenicity and carcinogenicity are harmful to the soil environment, etc., and achieve a long period of stability , low cost, and the effect of improving soil physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation of chromium-contaminated soil: take 200g of uncontaminated dry soil, weigh 400g of potassium dichromate solution with a concentration of 500mg / L, spread a layer of soil, and spray potassium dichromate solution once, repeating this many times until dichromate Potassium acid potassium solution was added to the weighed soil, and then it was dried, crushed, sieved, and sterilized to obtain Cr 6+ Chromium-contaminated soil with a mass ratio of 500 mg / kg to the soil.

[0027] The TCLP (Toxicity Characteristic Leaching Procedure) method (promulgated by the US Environmental Protection Agency) is used to measure the soil leaching concentration. The soil sample is leached with an acetic acid solution with a pH of 2.88. The soil-water ratio (mass volume ratio) is 1:20. -1 Turn down and shake for 18-20h, use diphenylcarbazide spectrophotometry (GB / T15555.5-1995) to analyze Cr 6+ The concentration was tested, and the blank extract was used as a control during the experi...

Embodiment 1

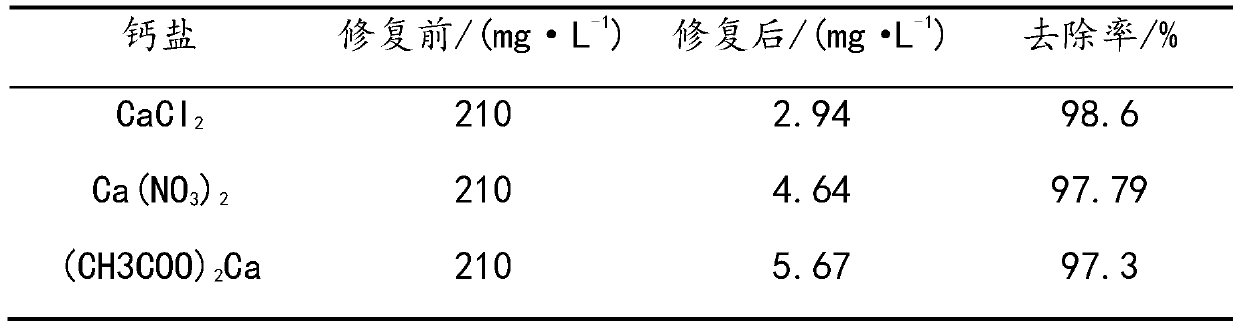

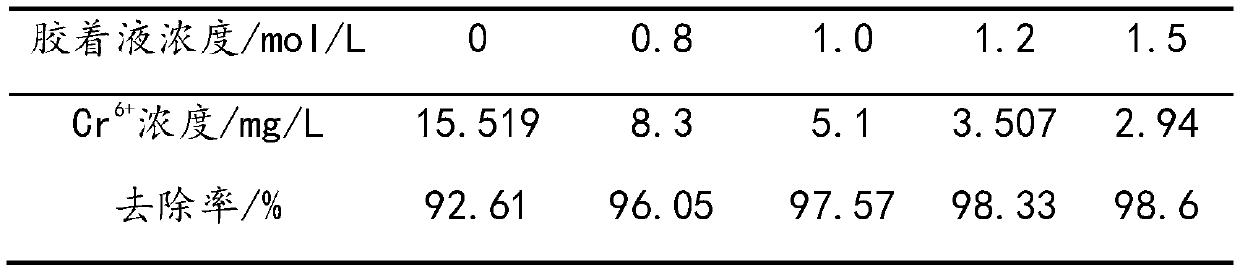

[0029] Take 33.3g of calcium chloride, 18g of urea and 200mL of distilled water and mix them uniformly to obtain the glue solution; take 20mL of the glue solution and 20mL of bacterial solution A and mix them evenly to get the reaction solution; take 20mL of the reaction solution and add 10g of chromium-contaminated soil to it Place it in a constant temperature incubator at 30°C for 30 days. After 30 days, extract it according to the TCLP method. It is measured that the concentration of hexavalent chromium in the contaminated soil leachate is reduced from 210 mg / L to 2.94 mg / L, and the removal rate of Cr is 98.6 %.

Embodiment 2

[0031] With Example 1, the difference is that the glue solution is obtained after the urea of 70.8g calcium nitrate and 18g is dissolved in 200mL of distilled water and mixed uniformly, and the concentration of hexavalent chromium in the polluted soil leachate is reduced from 210mg / L to 4.64mg / L, the removal rate of Cr is 97.79%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com