A high-precision mold production process

A production process and high-precision technology, applied in the field of mold manufacturing, can solve the problems of electrode processing accuracy, positioning accuracy, large influence of translational motion, poor control of processing parameters, inaccurate electrode positioning, etc., to achieve simple process and improve heat dissipation Effect of poor exhaust and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

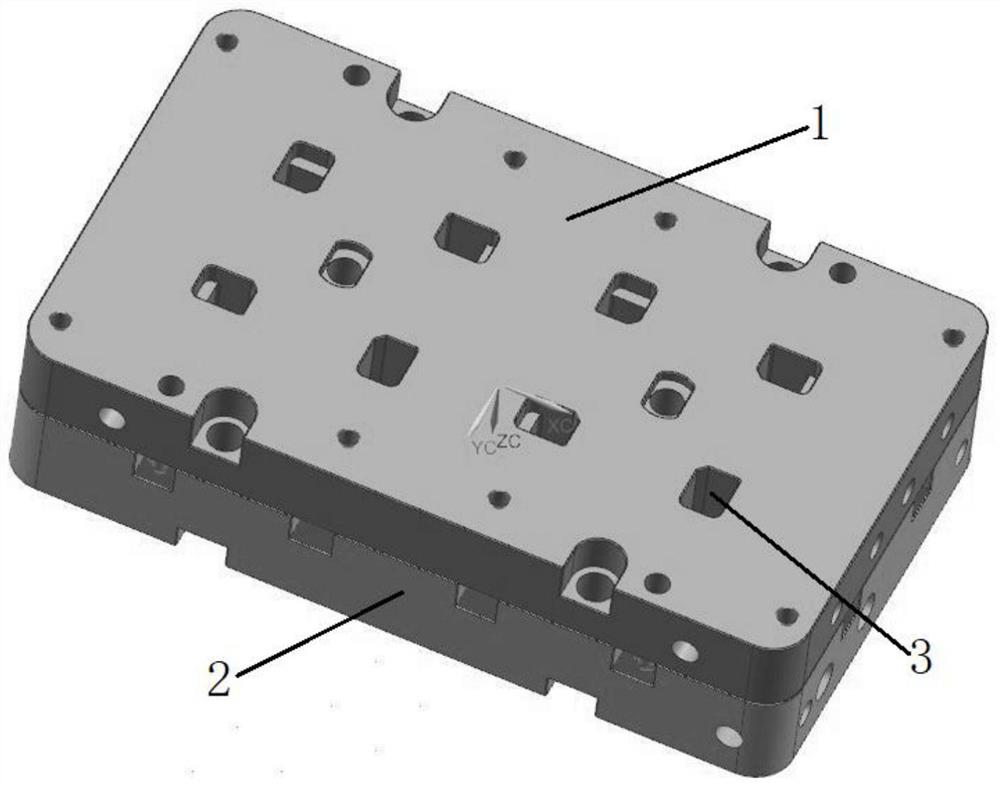

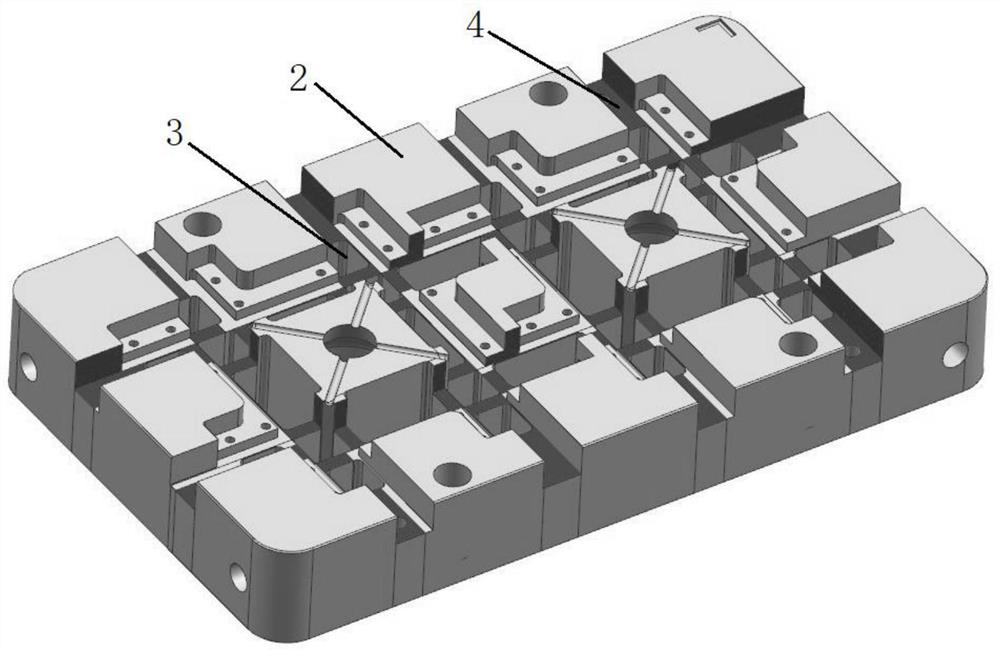

[0037] refer to Figure 1-5 Shown is the preferred embodiment provided by the present invention.

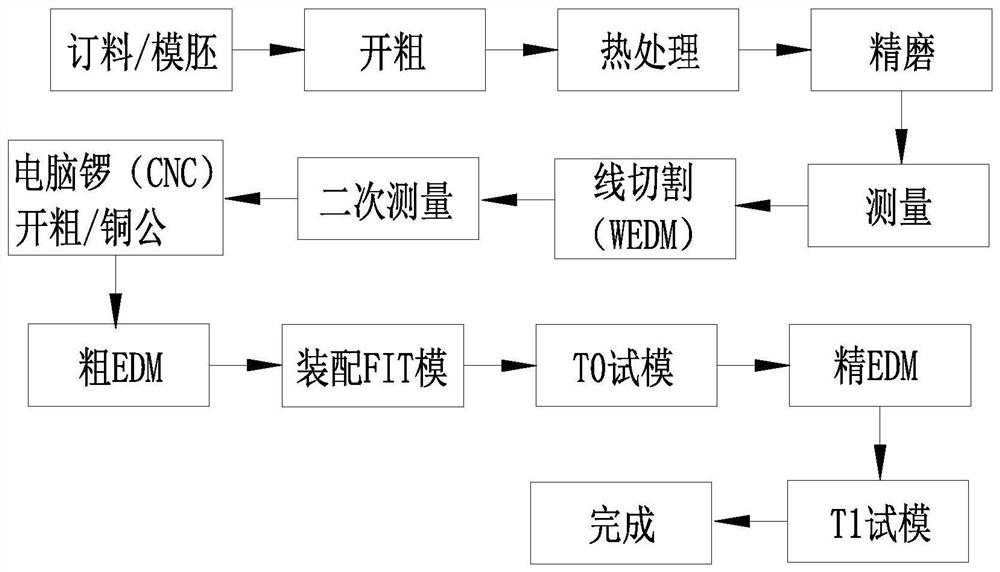

[0038] A high-precision mold production process, specifically comprising the following steps:

[0039] S1. Order material / mold base: preliminarily screen out the mold base material, and perform preliminary processing on the mold base material, and remove the mold base material with large internal particles;

[0040] S2. Rough cutting: process the mold base material with machine tools, and process the general shape of the mold, and leave a margin around the mold;

[0041] S3. Pre-processing: heat treatment is carried out on the mold obtained in S2, after the heat treatment is completed, fine grinding is carried out, and the side wall is measured after the fine grinding is completed to ensure the accuracy;

[0042] S4. Wire cutting process: use the continuously moving electrode wire as the electrode, perform pulse spark discharge on the workpiece to remove metal, cut and shape, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com