Method for preparing radish leaf dietary fiber powder

A technology of dietary fiber powder and radish leaves, applied in food science and other directions, can solve problems such as environmental pollution, poor taste, and low utilization rate, and achieve the effects of improving economic value and regulating blood sugar and blood lipid levels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

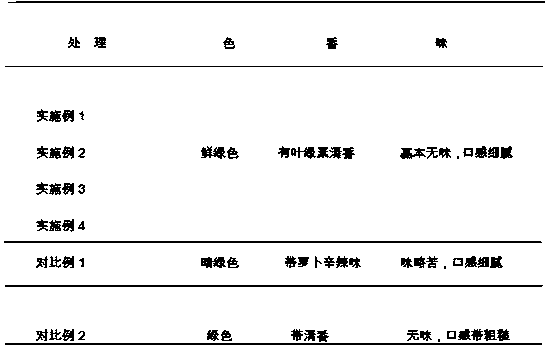

Examples

Embodiment 1

[0019] A preparation method of radish leaf dietary fiber powder, the method comprises the steps:

[0020] 1) Selection of raw materials: select fresh radish leaves without pests, and remove roots, yellow leaves and dead leaves;

[0021] 2) Washing and soaking: Wash the radish leaves in step (1) with water, soak them in 1% (w / v) baking soda and 3% (w / v) salt water for 20 minutes, take them out, and rinse with water twice;

[0022] 3) Centrifugation: centrifuging and dehydrating the radish leaves in step (2), and the centrifugal speed is 1000 rpm;

[0023] 4) Drying: Dry the radish leaves dehydrated in step (3) at 85°C for 1 hour, then cool down to 50°C and continue to bake for 1.5 hours;

[0024] 5) Pulverization: pulverize the dried radish leaves in step (4) with a pulverizer, and seal them for later use;

[0025] 6) Enzymatic hydrolysis: add plant protease to the radish leaf powder in step (5), the ratio of material to liquid (g / L) is 1:15, adjust the pH to 7.2, and carry o...

Embodiment 2

[0029] A preparation method of radish leaf dietary fiber powder, the method comprises the steps:

[0030] 1) Selection of raw materials: select fresh radish leaves without pests, and remove roots, yellow leaves and dead leaves;

[0031] 2) Washing and soaking: Wash the radish leaves in step (1) with water, soak them in 1% (w / v) baking soda and 3% (w / v) salt water for 25 minutes, take them out, and rinse with water twice;

[0032] 3) Centrifugation: centrifuging and dehydrating the radish leaves in step (2), and the centrifugal speed is 1000 rpm;

[0033] 4) Drying: bake the dehydrated radish leaves in step (3) at 85°C for 1.5 h, then cool down to 50°C and continue to bake for 1.0 h;

[0034] 5) Pulverization: pulverize the dried radish leaves in step (4) with a pulverizer, and seal them for later use;

[0035] 6) Enzymatic hydrolysis: add plant protease to the radish leaf powder in step (5), the ratio of material to liquid (g / L) is 1:15, adjust the pH to 7.2, and carry out e...

Embodiment 3

[0039] A preparation method of radish leaf dietary fiber powder, the method comprises the steps:

[0040] 1) Selection of raw materials: select fresh radish leaves without pests, and remove roots, yellow leaves and dead leaves;

[0041] 2) Washing and soaking: Wash the radish leaves in step (1) with water, soak them in 1% (w / v) baking soda and 3% (w / v) salt water for 30 minutes, take them out, and rinse with water twice;

[0042] 3) Centrifugation: centrifuging and dehydrating the radish leaves in step (2), and the centrifugal speed is 1000 rpm;

[0043] 4) Drying: bake the dehydrated radish leaves in step (3) at 85°C for 1.5 h, then cool down to 50°C and continue to bake for 1.0 h;

[0044] 5) Pulverization: pulverize the dried radish leaves in step (4) with a pulverizer, and seal them for later use;

[0045] 6) Enzymatic hydrolysis: add plant protease to the radish leaf powder in step (5), the ratio of material to liquid (g / L) is 1:20, adjust the pH to 7.2, and carry out e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com