Deep penetrating fillet welding process for hydraulic support structure piece mid-thickness plate welding

A technology of hydraulic support and deep penetration fillet welding, which is applied in welding equipment, manufacturing tools, arc welding equipment, etc., to achieve the effects of reduced power consumption, energy saving and consumption reduction, comprehensive performance of weld seam, and increased penetration depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be further described in detail below.

[0028] A deep penetration fillet welding process for welding medium and thick plates of hydraulic support structures, comprising the following steps:

[0029] Step 1: Place the medium-thick plate workpiece in the flat fillet welding position, and clean up the oil, dirt and rust in the area to be welded and within 20mm on both sides;

[0030] Step 2, the welding torch is connected to the welding power supply, and the welding shielding gas and solid welding wire are prepared;

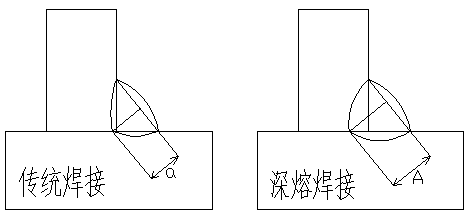

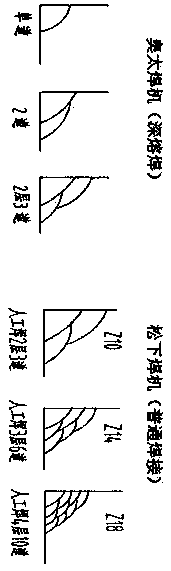

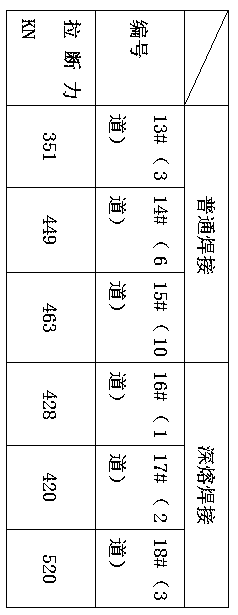

[0031] Step 3, use a welding machine to weld, the angle between the welding torch and the medium-thick plate in the horizontal direction is 35º±2º, the angle between the welding torch and the medium-thick plate in the vertical direction is 90º±5º, and the tip of the welding wire is 2mm away from the bottom edge of the vertical plate. The size of the weld angle of the weld seam is 8-10mm, and it is welded by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com