Polyester modified epoxy acrylate resin and preparation method and application thereof

A technology of epoxy acrylate and polyester acrylate, applied in the field of coatings, can solve the problems of insufficient flexibility, high brittleness of cured film, unfavorable anti-aging and anti-yellowing properties, etc., and achieve improved hardness, high hardness and tight structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of above-mentioned polyester acrylate, comprises the steps:

[0043] Mix the hydroxyethyl acrylate b, phthalic anhydride b and catalyst b, raise the temperature for the first time, and react to obtain a mixture A;

[0044] When the acid value of the system is 210mgKOH / g-218mgKOH / g, add the epichlorohydrin and polymerization inhibitor b to the mixture A, heat up for the second time, and react to obtain the mixture B;

[0045] When the acid value of the system is less than or equal to 5 mgKOH / g, the material is filtered out to obtain the polyester acrylate.

[0046] Preferably, for the first temperature rise, the temperature is 100°C-110°C, and the reaction time is 2h-3h.

[0047] Preferably, for the second temperature rise, the temperature is 110°C-120°C, and the reaction time is 3h-4h.

[0048] The present invention also provides the preparation method of above-mentioned polyester modified epoxy acrylate resin, comprises the steps:

[0049] Mix...

Embodiment 1

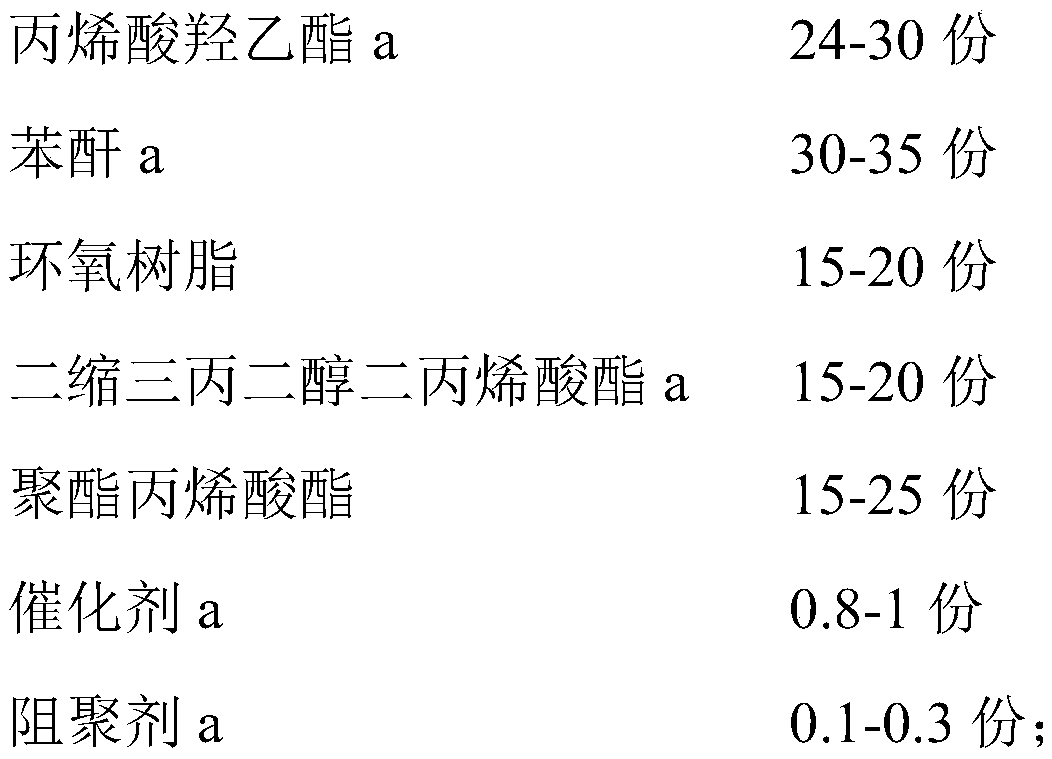

[0071] This embodiment provides a polyester modified epoxy acrylate resin, which is prepared from the following components by weight:

[0072] 30 parts of hydroxyethyl acrylate a, 35 parts of phthalic anhydride a, 0.8 parts of catalyst a N,N-dibutylamine, 20 parts of epoxy resin YN1828, 0.2 parts of p-hydroxyanisole of polymerization inhibitor a, tripropylene glycol di 20 parts of acrylate a and 20 parts of polyester acrylate;

[0073] The polyester acrylate is prepared from components comprising the following parts by weight:

[0074] 28 parts of hydroxyethyl acrylate b; 35 parts of phthalic anhydride b; 0.8 parts of catalyst b N,N-dibutylamine; 22 parts of epichlorohydrin; 0.2 parts of polymerization inhibitor b p-hydroxyanisole.

[0075] The preparation method of above-mentioned polyester acrylate, comprises the steps:

[0076] Mix the hydroxyethyl acrylate b, phthalic anhydride b and N,N-dibutylamine, raise the temperature for the first time, the temperature is 90°C-95°C...

Embodiment 2

[0086] This embodiment provides a polyester modified epoxy acrylate resin, which is prepared from the following components by weight:

[0087] 30 parts of hydroxyethyl acrylate a, 35 parts of phthalic anhydride a, 0.8 parts of catalyst a N,N-dibutylamine, 0.2 parts of epoxy resin E-4416 parts, polymerization inhibitor a p-hydroxyanisole, 0.2 parts of tripropylene glycol 20 parts of diacrylate a and 20 parts of polyester acrylate;

[0088] The polyester acrylate is prepared from components comprising the following parts by weight:

[0089] 33 parts of hydroxyethyl acrylate b; 40 parts of phthalic anhydride b; 0.8 parts of catalyst b N,N-dibutylamine; 28 parts of epichlorohydrin; 0.2 parts of polymerization inhibitor b p-hydroxyanisole.

[0090] The preparation method of above-mentioned polyester acrylate, comprises the steps:

[0091] Mix the hydroxyethyl acrylate b, phthalic anhydride b and N,N-dibutylamine, raise the temperature for the first time, the temperature is 95°C-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com