Recovery method and device for helium in flash steam of liquefied natural gas

A technology of liquefied natural gas and recovery device, applied in the field of waste gas recovery, can solve the problems of reduction of natural gas liquefaction, influence of heat exchange efficiency, increase of BOG gas volume, etc., to achieve the effect of improving recovery rate, improving product purity and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

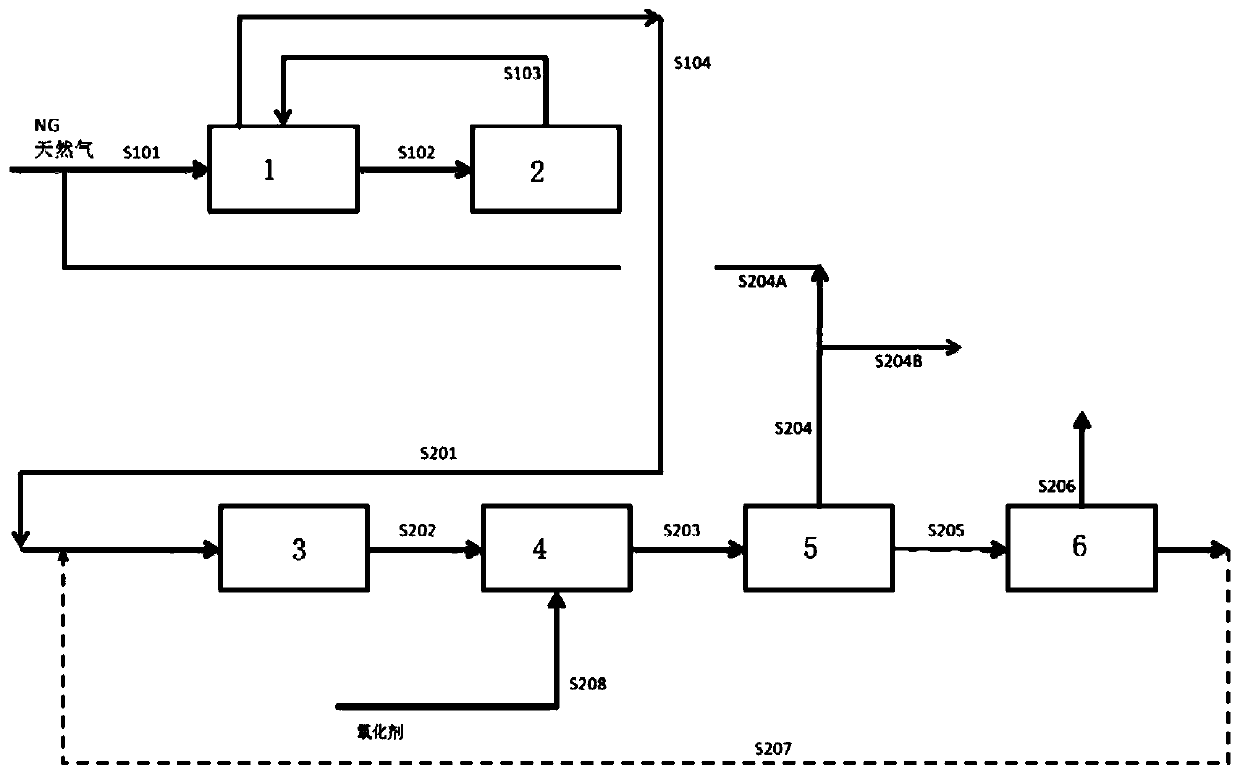

[0064] This embodiment provides a recovery device for helium in the BOG of liquefied natural gas in a small and medium-sized factory, the structure of the recovery device is as follows figure 1 shown.

[0065] The recovery device includes a cold box 1 , a liquefied natural gas storage tank 2 , a compression unit 3 , a purification unit 4 , a membrane separation unit 5 , and a pressure swing adsorption unit 6 .

[0066] Wherein, the cold box 1 is provided with a natural gas inlet port and a first inlet port, a first outlet port and a second outlet port, the liquefied natural gas storage tank is provided with an inlet port and an outlet port, the compression unit is provided with an inlet port and an outlet port, and the purification unit An inlet port and an outlet port are provided, the membrane separation unit is provided with an inlet port and an outlet port, and the pressure swing adsorption unit is provided with an inlet port and an outlet port;

[0067] The first outlet ...

Embodiment 2

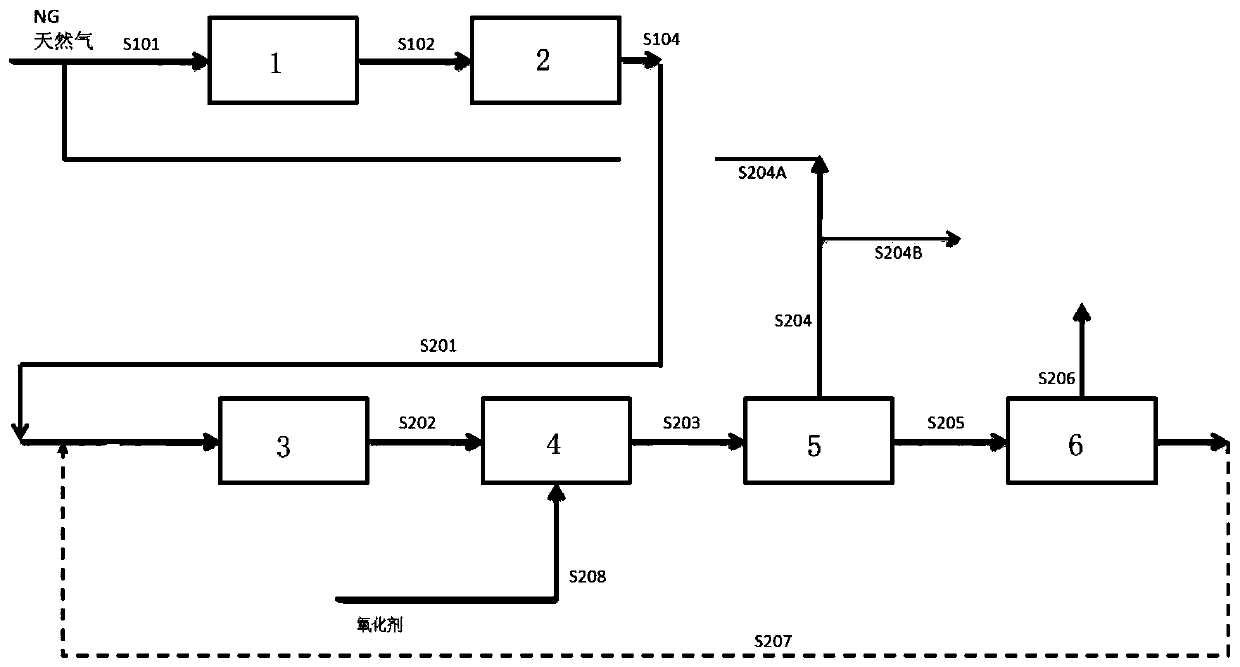

[0082] Such as figure 2 As shown, this embodiment provides a helium recovery device for direct pressurization of BOG tail gas.

[0083] The device is compatible with figure 1 The difference of the devices shown is only that: the cold box is only equipped with a natural gas inlet port and a first outlet port, the first outlet port of the cold box is connected with the inlet port of the LNG storage tank, and the outlet port of the LNG storage tank is connected with the compression unit The inlet port of the compression unit is connected, the outlet port of the compression unit is connected with the inlet port of the purification unit, the outlet port of the purification unit is connected with the inlet port of the membrane separation unit, and the outlet port of the membrane separation unit is connected with the inlet port of the pressure swing adsorption unit.

[0084] This embodiment provides a helium recovery method for direct pressurization of BOG tail gas, which can be ac...

Embodiment 3

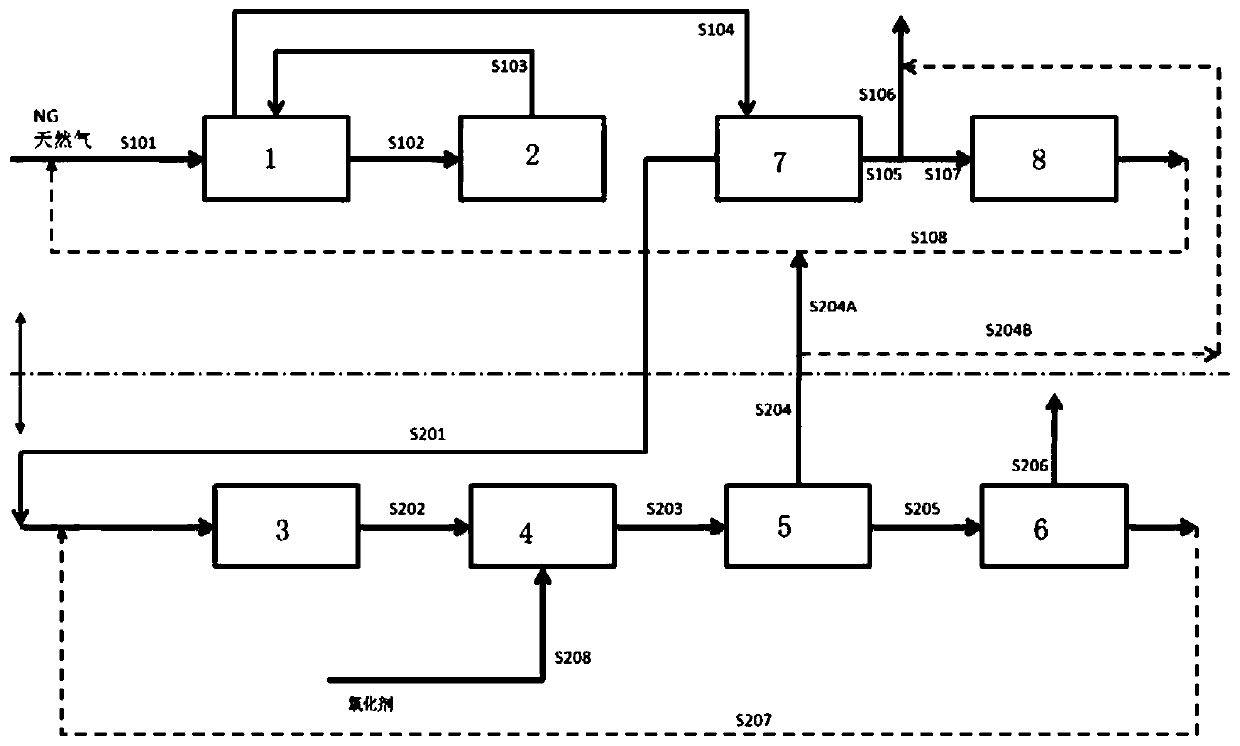

[0090] Such as image 3 As shown, this embodiment provides a device for recovering helium in BOG tail gas combined with an existing LNG plant.

[0091] The recycling unit and figure 1 The arrangement shown differs in that it also includes a compressor 7 and a booster 8 .

[0092] The inlet port of the compressor 7 communicates with the second outlet port of the cold box.

[0093] The first outlet port of the compressor 7 communicates with the inlet port of the compression unit 3 , and the second outlet port of the compressor 7 communicates with the inlet port of the booster 8 .

[0094] The outlet port of the supercharger 8 communicates with the natural gas inlet port of the cold box 1 .

[0095] The recovery outlet port of the membrane separation unit 5 is connected to the outlet port of the supercharger 8 and the natural gas inlet port of the cold box 1 .

[0096] This embodiment provides a method for recovering helium in BOG tail gas combined with existing LNG plants, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com