MAG welding process for austenitic stainless steel pipeline

A technology of austenitic stainless steel and welding process, which is applied in welding equipment, welding/welding/cutting items, applications, etc., can solve the problems of high welding cost of argon arc welding, dependence on welding quality, increased equipment investment, etc. Quality and efficiency, saving cost and auxiliary time, increasing the effect of deposited metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

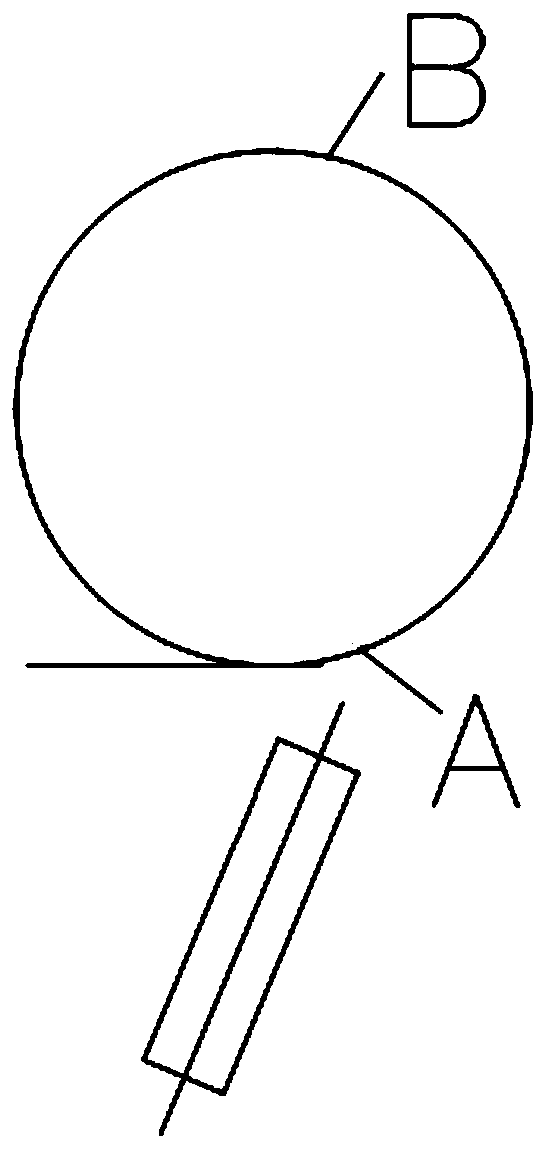

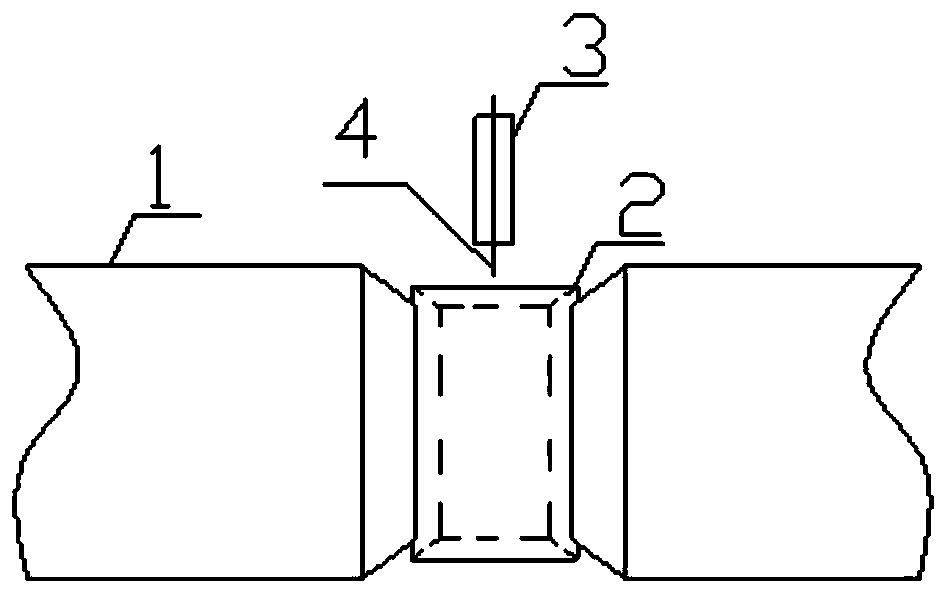

[0033] The semi-automatic MAG welding process for austenitic stainless steel pipes in this embodiment includes the following steps: Step 1. Preparation before welding: (1) Welding base material: select austenitic stainless steel with a thickness of more than 60mm as the base material 1, for example 0Cr18Ni9; choose austenitic ferritic two-way steel pipe as the pipe body, choose the liner 3 with the same chemical composition as the base metal 1, and process it into two semicircular isosceles trapezoidal rings with the same inner diameter as the pipe 2.

[0034] (2) Welding material: Select stainless steel welding wire 5 similar in composition to base metal 1, for example, 0Cr18Ni9 selects stainless steel flux-cored welding wire TFW-308L.

[0035] (3) Welding equipment: Welding equipment 4 adopts the CO2 / MAG welding machine of the inverter processor, which has adjustment functions such as initial stage, welding guard, and diversification. It uses 98% Ar and 2% CO2 MAG welding for...

Embodiment 2

[0051] The automatic MAG welding process for austenitic stainless steel pipes in this embodiment includes the following steps: Step 1. Preparation before welding: (1) Welding base material: select austenitic stainless steel with a thickness of more than 108mm as the base material 1, for example 0Cr18Ni9; choose austenitic ferritic two-way steel pipe as the pipe body, choose the liner 3 with the same chemical composition as the base metal 1, and process it into two semicircular isosceles trapezoidal rings with the same inner diameter as the pipe 2.

[0052] (2) Welding material: Select stainless steel welding wire 5 similar in composition to base metal 1, for example, 0Cr18Ni9 selects stainless steel flux-cored welding wire TFW-308L.

[0053] (3) Welding equipment: Welding equipment 4 adopts a CO2 / MAG welding machine with an outstretched arm or a welding robot arm, and uses 98% Ar and 2% CO2 MAG welding for welding, and 98% Ar can be used for welding from pipes 2 The front side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com