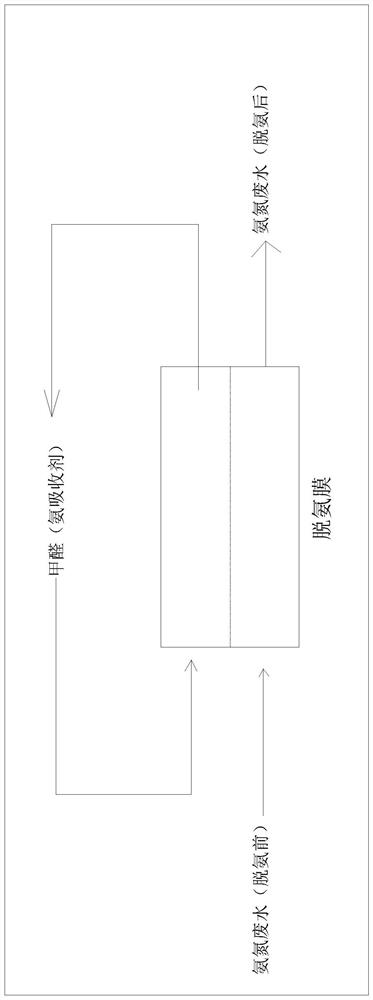

A method for treating high ammonia nitrogen wastewater with formaldehyde as ammonia absorbent

A technology for ammonia nitrogen wastewater and ammonia absorption, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problem that the recovery value of ammonium sulfate is not very high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The ammonium sulfate wastewater produced by a rare earth processing enterprise has been tested and found that the pH of the wastewater is 5, the ammonia nitrogen is 880ppm, and the conductivity is 1.7ms / cm.

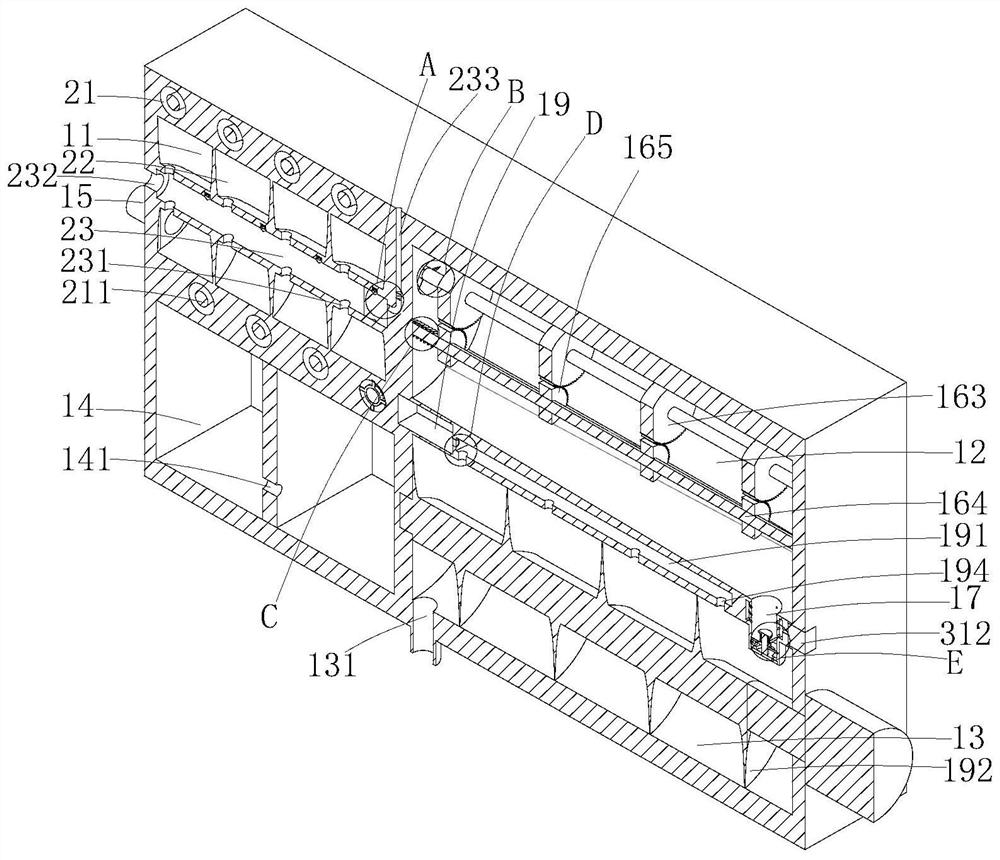

[0033]A method for treating high-ammonia-nitrogen wastewater using formaldehyde as an ammonia absorbent, comprising the following steps: a. Raw material preparation: preparing ammonia-nitrogen wastewater pretreated by ultrafiltration; Adjustment of PH value; c. deamination: absorb the deamination film after dehydration by formaldehyde solution; d. output: classify and export the deamination wastewater and urotropine generated after deamination treatment; The ammonia nitrogen concentration in the ammonia nitrogen wastewater in step a is 300-10000mg / L; the heating temperature in the step b is 35-45°C, and the pH value of the ammonia nitrogen wastewater is adjusted to 10-12; The ammonia membrane is a hydrophobic microporous membrane, and its material is polypropylene,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com