In-situ sludge recycling system device

A system device and in-situ technology, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, water pollutants, etc., can solve the problem of difficult odor tail gas, high fuel cost, poor activity, etc. problem, to achieve the effect of efficient, sustainable and controllable production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

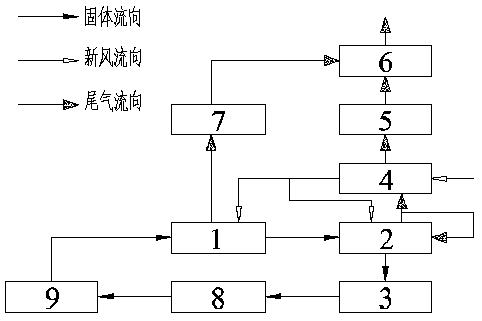

[0040] A sludge in-situ recycling system device, including a vertical unpowered spiral stirring biological drying device 1, a vertical sandless jet flow carbonization furnace 2, a pulverizing vacuum liquefaction device 3, a tail gas wet treatment device 6, and a dust collector 5 , heat exchanger 4, negative pressure device 7;

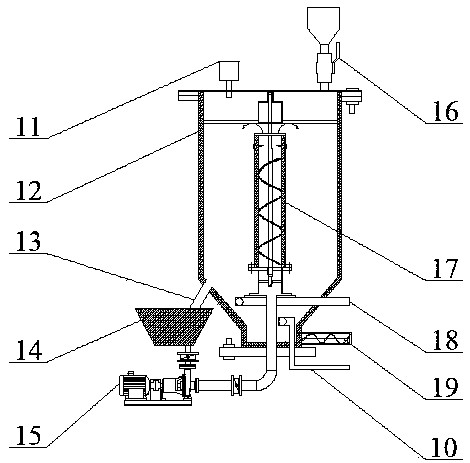

[0041]Vertical non-powered spiral stirring biological drying device 1, including the main body of the drying device and the stirring device; There is a feed inlet 16 and a biological drying outlet 11. The biological drying outlet 11 is connected to the negative pressure device 7. The bottom is conical, and the angle of the cone is designed to be <45°, which is easy to promote the sliding and mixing of sludge. A dried biomass outlet 19 and a liquid discharge port 10 are arranged at the bottom of the cone, an air inlet is provided at the middle of the cone, and an air inlet pipe 18 is arranged inside. One end of the air inlet pipe 18 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com