Production device and process for co-producing fuel ethanol and special-grade edible alcohol

A technology for edible alcohol and fuel ethanol, which is applied in the preparation of alcoholic beverages, chemical instruments and methods, and the preparation of organic compounds. Improve market adaptability and facilitate the effect of waste removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

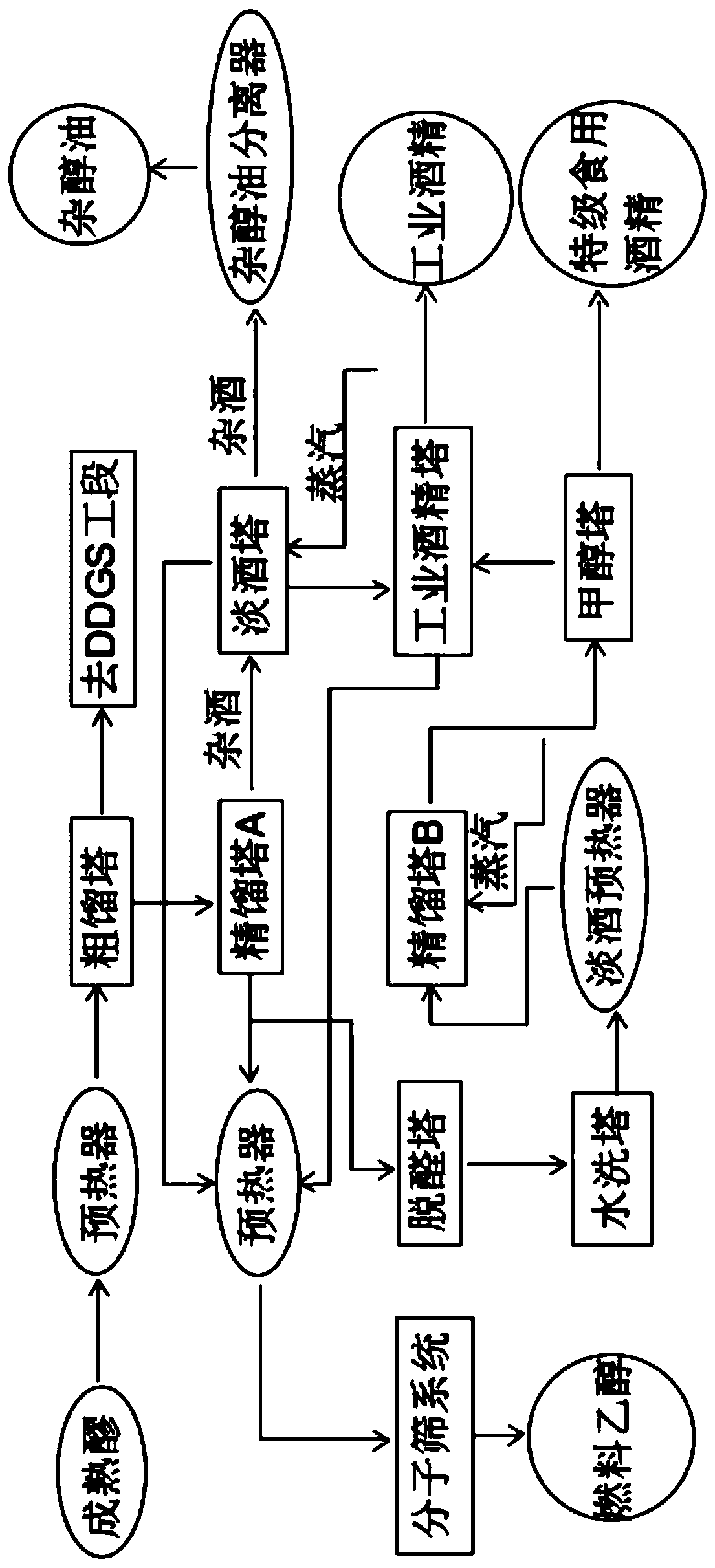

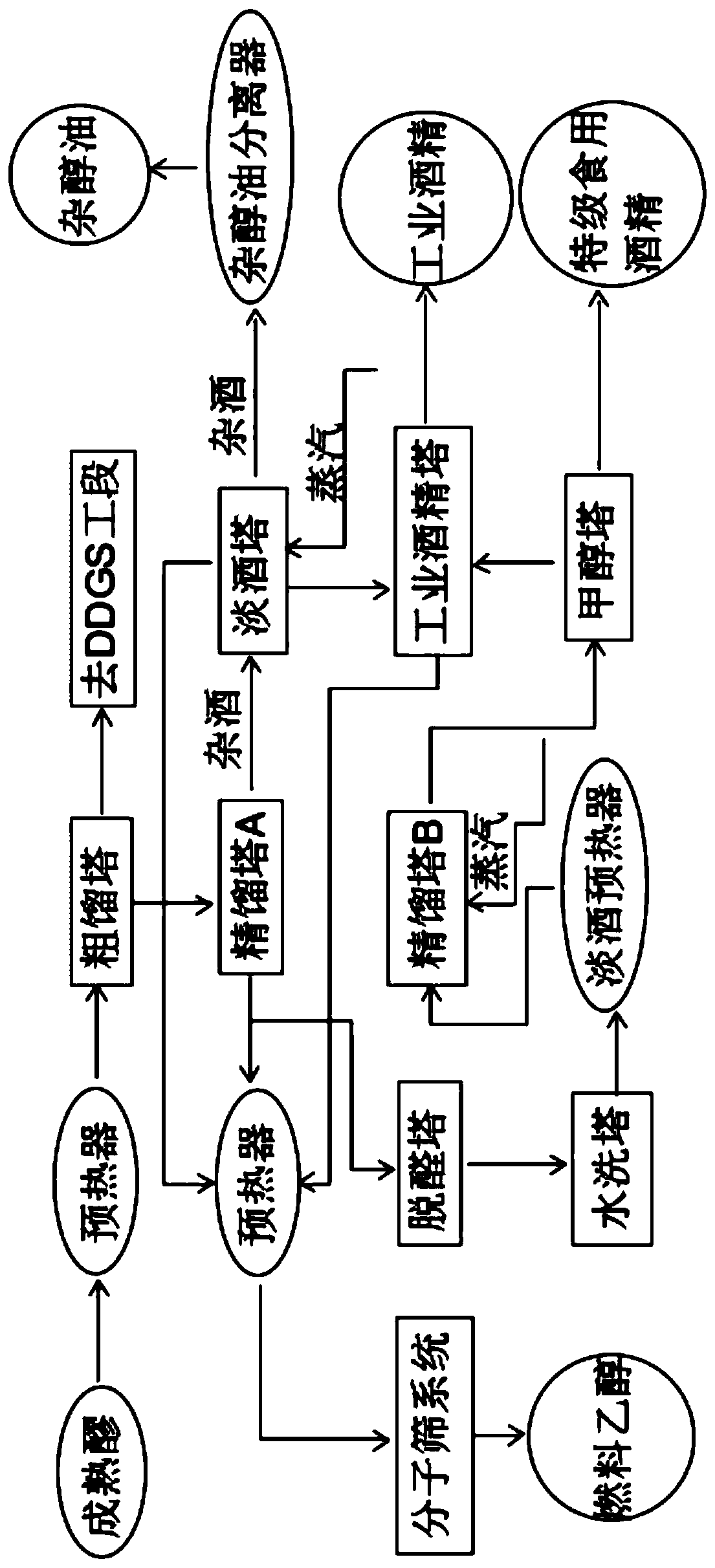

[0046] Operate the crude distillation tower, rectification tower A, light wine tower and molecular sieve dehydration system for the production of fuel ethanol, the specific method is as follows:

[0047] The mature mash from fermentation enters the degassing section of the crude distillation tower through the first preheater, and the degassed mash enters the stripping section of the crude distillation tower; the gas phase crude wine vapor after distillation in the crude distillation tower enters the refining Distillation tower A, the light wine extracted from the bottom of rectification tower A is preheated and then enters the light wine tower; the liquor produced from rectification tower A and light wine tower is heated in the liquid phase by the second preheater, and then enters the molecular sieve dehydration system for dehydration Finally, the finished fuel ethanol is obtained.

[0048] In this process, the light wine tower is indirectly heated by raw steam, and the wine v...

Embodiment example 2

[0050] The crude distillation tower, rectification tower A, dealdehyde tower, water washing tower, rectification tower B, methanol tower, industrial alcohol tower, light wine tower are running, and the molecular sieve dehydration system is not in operation. It is used to produce special-grade edible alcohol. The specific method is as follows:

[0051] The mature mash from fermentation is preheated by the first preheater and enters the degassing section of the crude distillation tower, and the degassed mash enters the stripping section of the crude distillation tower; the gas phase crude wine vapor after distillation in the crude distillation tower Enter the rectification tower A, and 95% of the wine liquor from the upper area of the rectification tower A enters the dealdehyde tower; the wine liquor after dealdehyde in the dealdehyde tower enters the water washing tower, and the light liquor after washing and extracting impurities is passed through After preheating by the ligh...

Embodiment example 3

[0055] Refer to the implementation cases 1 and 2 for the heating methods of each tower, run the crude distillation tower, rectification tower A, dealdehyde tower, water washing tower, rectification tower B, methanol tower, industrial alcohol tower, light wine tower and molecular sieve dehydration system for Co-production of special-grade edible alcohol and fuel ethanol, the specific method is as follows:

[0056] The mature mash from fermentation enters the degassing section of the crude distillation tower through the first preheater, and the degassed mash enters the stripping section of the crude distillation tower, and the gas phase crude wine vapor after distillation in the crude distillation tower enters the refining Distillation column A.

[0057] A part of the liquid phase in rectification tower A is taken out of the dealdehyde tower, and the wine liquor after dealdehyde enters into the water washing tower, and the light liquor after water washing and extraction of impur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com