Process for extracting polysaccharide from hericium erinaceus spore powder

An extraction process and polysaccharide extraction technology, applied in the field of chemical extraction of active ingredients, can solve problems such as untargeted utilization of Hericium erinaceus spore powder, damage to polysaccharide function, and destruction of polysaccharide structure, and are suitable for large-scale industrial production. , The effect of high weight average molecular weight and high extraction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of extraction process of polysaccharide in Hericium erinaceus spore powder, comprises the steps:

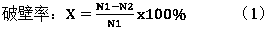

[0038] S1. Hericium erinaceus spore powder is subjected to jet crushing to obtain broken wall Hericium erinaceus spore powder;

[0039] S2. The broken Hericium erinaceus spore powder was mixed with a mannitol solution with a mass concentration of 28% according to the material-to-liquid ratio of 1g: 60mL, and heated to 45°C for 70 minutes to obtain a broken Hericium erinaceus spore powder solution;

[0040] S3. Introduce nitrogen gas into the solution of Hericium erinaceus spore powder, keep it for 12 minutes under the pressure of 1 MPa, and then quickly reduce the pressure to standard atmospheric pressure to obtain the crude polysaccharide extract;

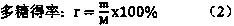

[0041] S4. Slowly add 95% ethanol with a volume concentration of 1:4 to the polysaccharide crude extract described in step S3, stir evenly, and after 12 hours of static precipitation, absorb the supernatant, and concent...

Embodiment 2

[0044] A kind of extraction process of polysaccharide in Hericium erinaceus spore powder, comprises the steps:

[0045] S1. Hericium erinaceus spore powder is broken and pulverized to obtain broken wall Hericium erinaceus spore powder;

[0046] The specific operation includes the following steps:

[0047] S-11. Add the pretreatment solution to the spore powder, the amount added is 290 ± 10g spore powder per liter of the pretreatment solution, stir evenly, and keep the temperature at 42°C for 45min to obtain the pretreatment product; the pretreatment The liquid is a mixture of purified water and glycerin, wherein the volume ratio of water to glycerin is 1:3.5;

[0048] S-12. The pre-treated substance was treated at minus 25 degrees Celsius for 70-75 minutes, and then heat-shocked at a temperature of 75±2°C for 60 minutes to obtain a primary treated substance;

[0049] S-13. Dry the primary treatment at 115°C, the second temperature at 80°C, and the third temperature at 45°C, ...

Embodiment 3

[0055] A kind of extraction process of polysaccharide in Hericium erinaceus spore powder, comprises the steps:

[0056] S1. Hericium erinaceus spore powder is subjected to jet crushing to obtain broken wall Hericium erinaceus spore powder;

[0057] The specific operation includes the following steps:

[0058] S-1. Add pretreatment liquid to the spore powder, the amount added is 320g spore powder per liter of pretreatment liquid, stir evenly, and keep warm at a temperature of 30°C for more than 45min to obtain a pretreatment product; the pretreatment liquid It is a mixture of purified water and glycerin, wherein the volume ratio of water to glycerin is 1:3.8;

[0059]S-2. The pre-treated substance was treated at minus 20 degrees Celsius for 1.5 hours, then heat-shocked at a temperature of 100 degrees Celsius for 50 minutes, and repeated again to obtain the primary treated substance;

[0060] S-3. Dry the primary treatment at 120°C, the second temperature at 90°C, and the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com