A speed regulation method for fans of subway energy-feedback devices based on power prediction

A fan speed regulation and power prediction technology, which is applied to components of pumping devices for elastic fluids, pump devices, mechanical equipment, etc., can solve the problems of large temperature rise difference of electronic components, fan oscillation, and IGBT power device service life Influence and other problems, to achieve the effect of low temperature rise and change, reduce fan power loss, and ensure long-term safe operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be specifically described below in conjunction with the accompanying drawings.

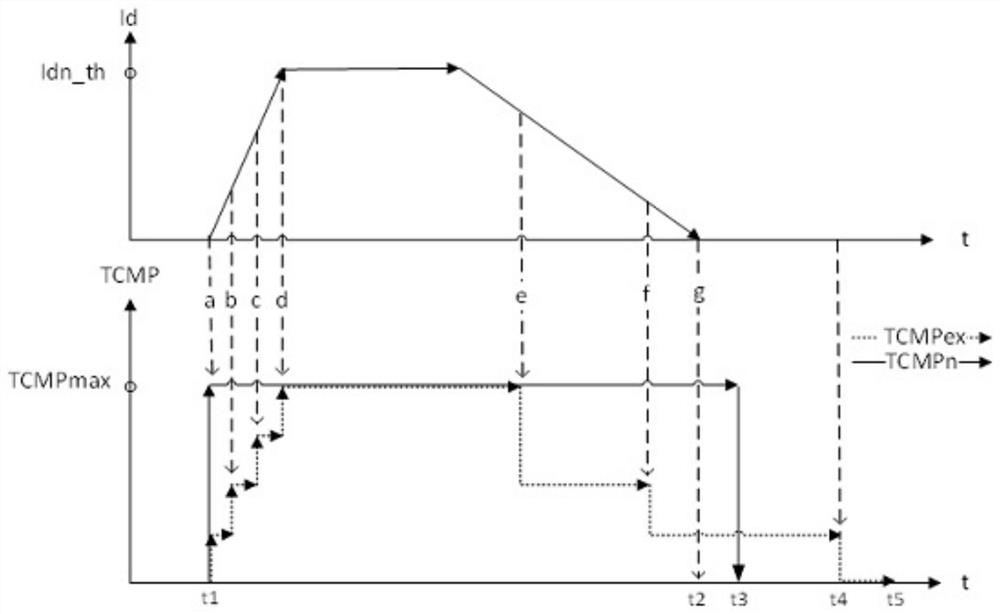

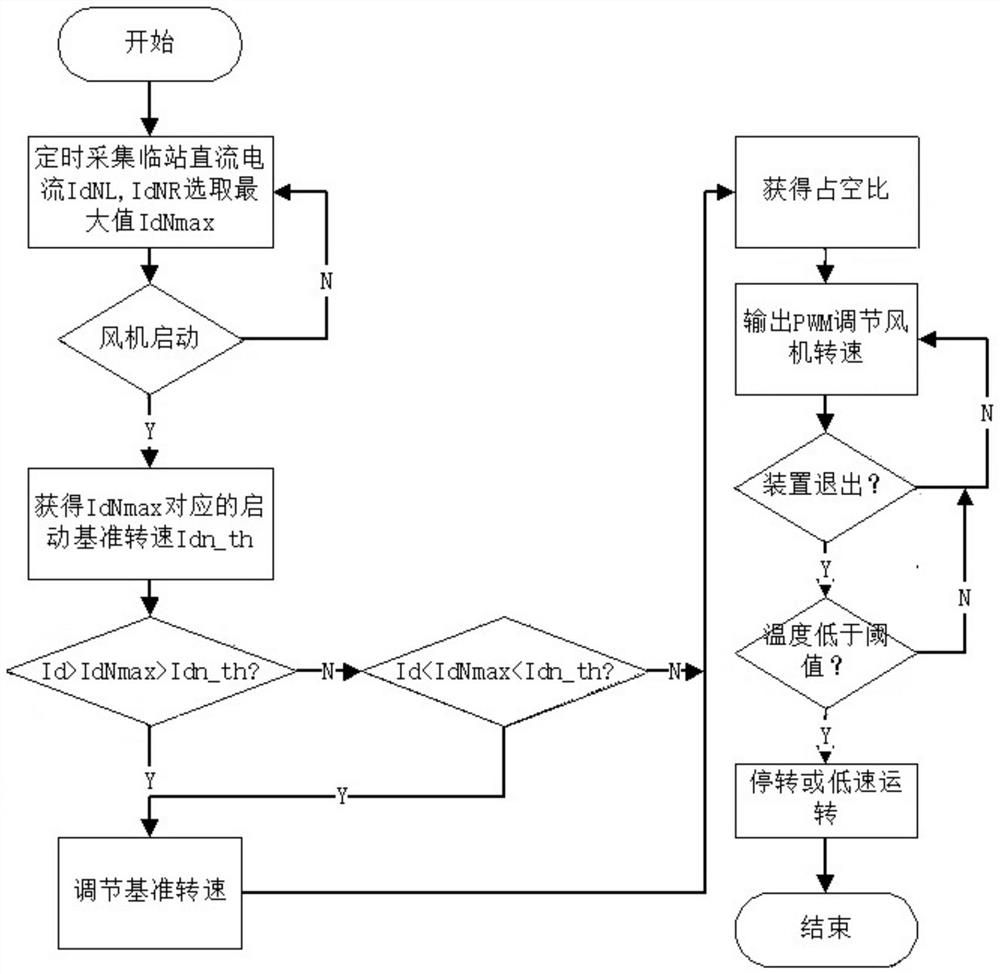

[0025] as attached figure 1 , 2 As shown, a method for adjusting the speed of a fan in a subway energy-feed device based on power prediction is characterized in that it includes the following steps:

[0026] Step 1: Collect and select the maximum power value of the feedback peak power of the subway energy feedback device on the adjacent platform in the previous braking period, and predict the peak feedback power of the platform in this braking period according to the power value to obtain The base value of the predicted power corresponding to the current is obtained, and the base value of the predicted power corresponding to the current is compensated and adjusted according to the output current of the subway energy feeder device collected in real time at the station.

[0027] Step 2: When the subway energy feedback device starts to start the brake feedback, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com