System and method for relieving blockage of air preheater through catalytic oxidation of escaping ammonia

A catalytic oxidation and air preheater technology is applied in the system field of fugitive ammonia catalytic oxidation to relieve air preheater blockage, and can solve the problems of insufficient output of induced draft fan, reduced efficiency of dust collector, limited unit load, etc. Reliable, avoids the effect of differential pressure rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

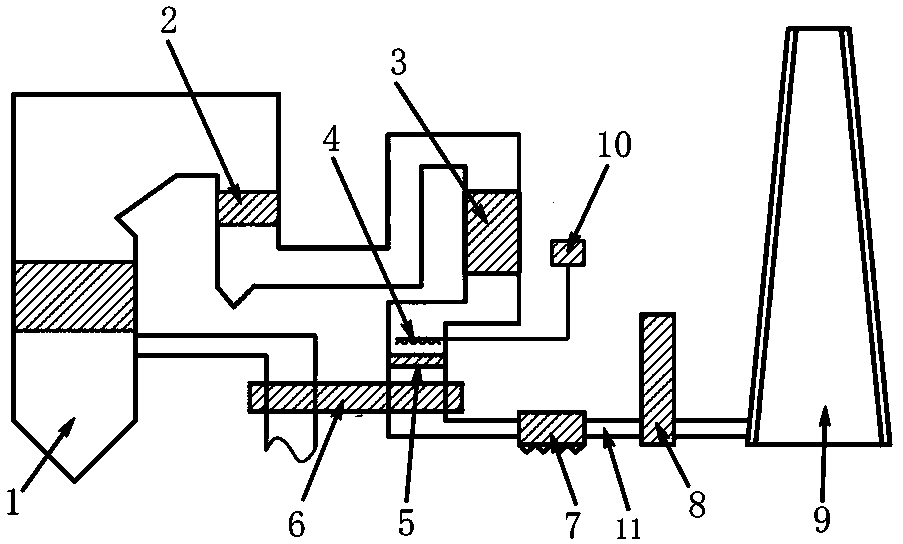

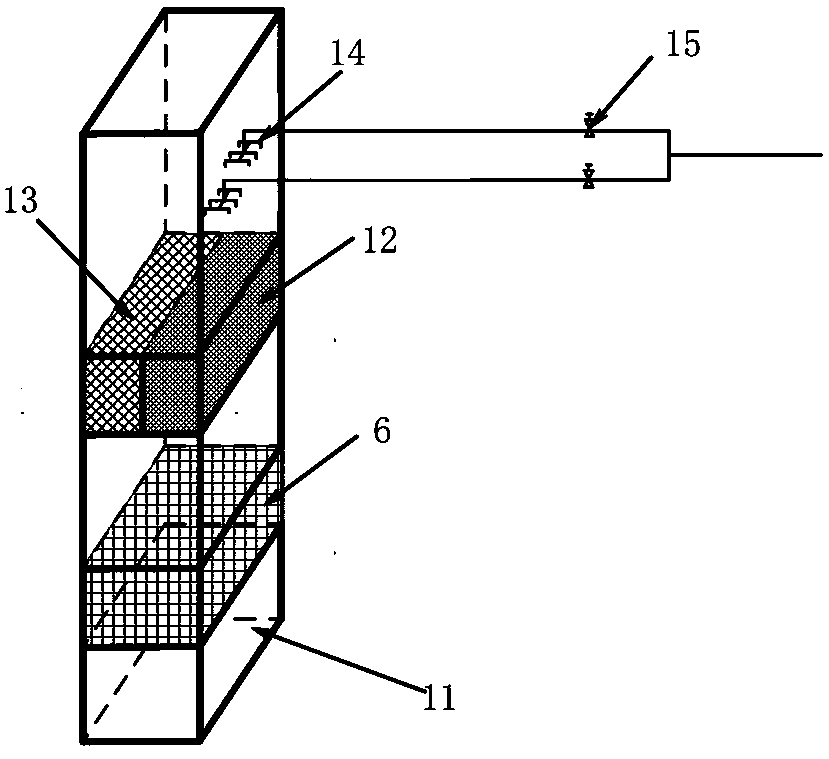

[0018] The present invention is a system for reducing the clogging of the air preheater 6 by catalytic oxidation of escaped ammonia, comprising a boiler 1 and a chimney 9. The passage 11 and the air intake channel are connected through the air preheater 6, and the flue 11 between the air preheater 6 and the boiler 1 is provided with an economizer 2 and an SCR denitrification reactor 3 in sequence, and the air preheater 6 and the The flue 11 between the chimneys 9 is provided with a limestone-gypsum wet desulfurization device 8;

[0019] An ozone injection device 4 is arranged in the flue 11 between the SCR denitrification reactor 3 and the air preheater 6, and a catalyst layer is arranged on the flue 11 between the ozone injection device 4 and the air preheater 6 5. The outlet of the ozone injection device 4 is set towards the catalyst layer 5, and the ozone injection device 4 is connected with an ozone generator 10 through a pipeline extending from the flue 11;

[0020] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com