Copper-based composite metal oxide mesocrystal microsphere as well as preparation method and application thereof

A copper-based composite and oxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, silicon compounds, etc., to improve catalytic activity and selectivity, efficient charge transport channels, simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

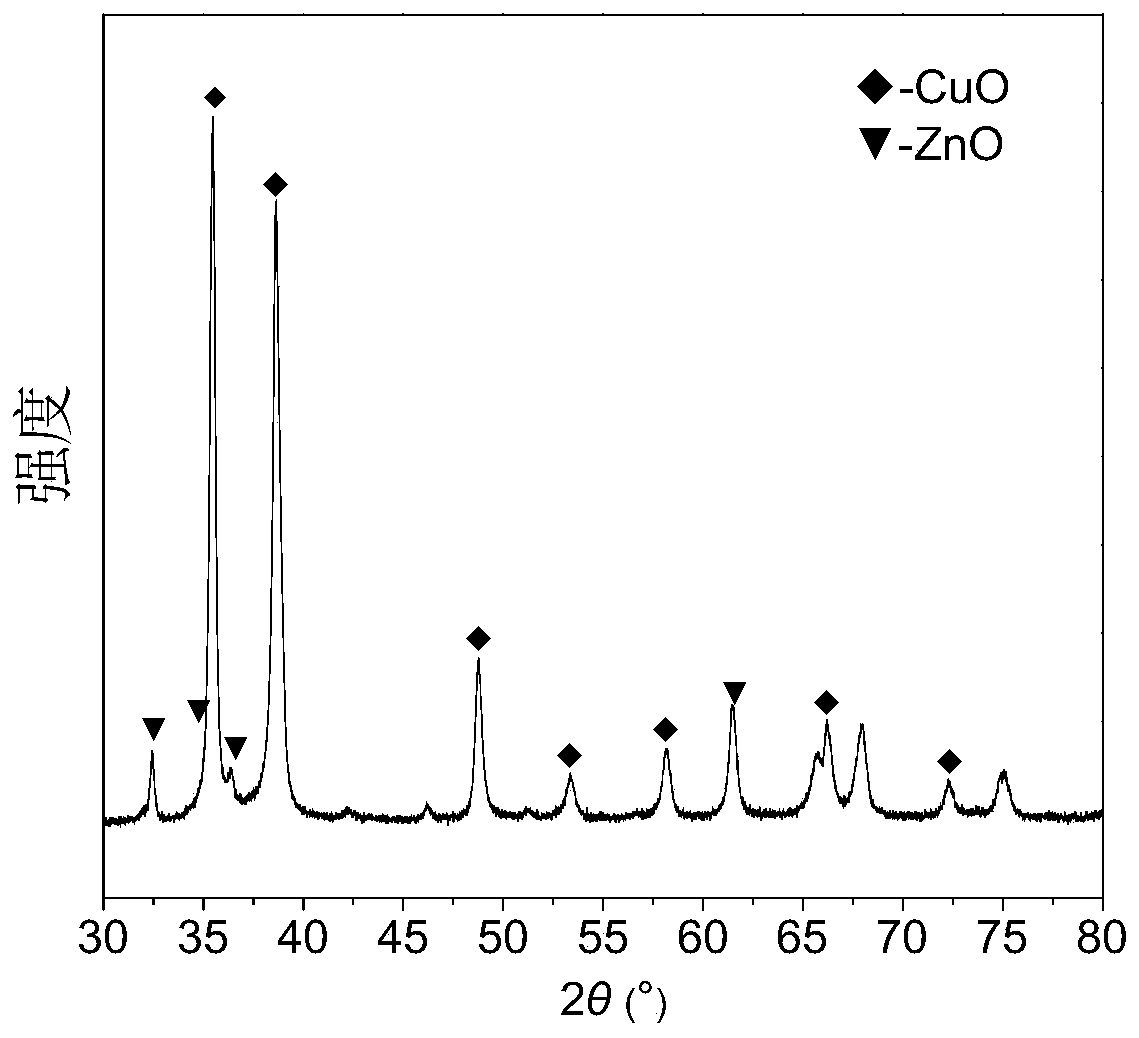

[0081] This embodiment provides a CuO-ZnO binary mesogenic material, the mesogenic material is arranged by uniformly oriented nanoparticles and has a spherical hollow core-shell structure with a particle size of about 13 μm, and both the outer shell and the inner core are porous shape, a nanoscale interface is formed between CuO and ZnO.

[0082] The preparation method of the CuO-ZnO binary mesogenic material is as follows:

[0083] 1) 2.5mmol Cu(NO 3 ) 2 ·3H 2 O and 0.25mmol Zn(NO 3 ) 2 ·6H 2 O was dissolved in 70mL DMF, stirred and mixed for 0.1h;

[0084] 2) Add 0.7 g of acetic acid to the above homogeneously mixed solution, and stir for 0.1 h;

[0085] 3) Then put it into an 80mL closed reactor for solvothermal reaction at 140°C for 6h;

[0086] 4) The solid obtained from the reaction in step 3) was washed, dried at 60° C. for 24 hours, and calcined at 400° C. for 3 hours in an air atmosphere to obtain the CuO—ZnO binary mesogenic material.

[0087] figure 1 is t...

Embodiment 2

[0094] This embodiment provides a CuO-Co 3 o 4 Binary mesogenic material, the mesogenic material is a spherical hollow core-shell structure with a particle size of about 13 μm formed by the arrangement of uniformly oriented nanoparticles, the outer shell and the inner core are both porous, CuO and Co 3 o 4 A nanoscale interface is formed between them.

[0095] The CuO-Co 3 o 4 The preparation method of the binary mesogen material is as follows:

[0096] 1) 2.4mmol Cu(NO 3 ) 2 ·3H 2 O and 0.5mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 70mL DMF, stirred and mixed for 6h;

[0097] 2) Add 0.7 g of sodium acetate to the above homogeneously mixed solution, and stir for 12 hours;

[0098] 3) Then put it into a 100mL airtight reactor for solvothermal reaction at 140°C for 24h;

[0099] 4) The solid obtained from the reaction in step 3) was washed, dried at 120°C for 12h, and calcined at 200°C for 24h in an air atmosphere to obtain the CuO-Co 3 o 4 Binary mesogenic materia...

Embodiment 3

[0101] This embodiment provides a CuO-NiO binary mesogenic material, the mesogenic material is arranged by uniformly oriented nanoparticles and has a spherical hollow core-shell structure with a particle size of about 15 μm, and both the outer shell and the inner core are porous. shape, a nanoscale interface is formed between CuO and NiO.

[0102] The preparation method of the CuO-NiO binary mesogenic material is as follows:

[0103] 1) Add 10mmol Cu(NO 3 ) 2 ·3H 2 O and 10mmol Ni(NO 3 ) 2·6H 2 O was dissolved in 600mL DMF, stirred and mixed for 12h;

[0104] 2) Add 7 g of acetic acid to the above homogeneously mixed solution, and stir for 6 hours;

[0105] 3) Then put it into a 1000mL closed reactor for solvothermal reaction at 130°C for 30h;

[0106] 4) The solid obtained from the reaction in step 3) was washed, dried at 100° C. for 4 hours, and calcined at 900° C. for 2 hours in an air atmosphere to obtain the CuO—NiO binary mesogenic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com