Preparation method and application of catalyst for photocatalytic degradation of VOCs

A catalyst and photocatalysis technology, applied in the field of photocatalysis, can solve the problems of low photocatalyst effective quantum yield and low light utilization rate, and achieve the effect of improving photocatalytic activity, improving catalytic performance and promoting effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

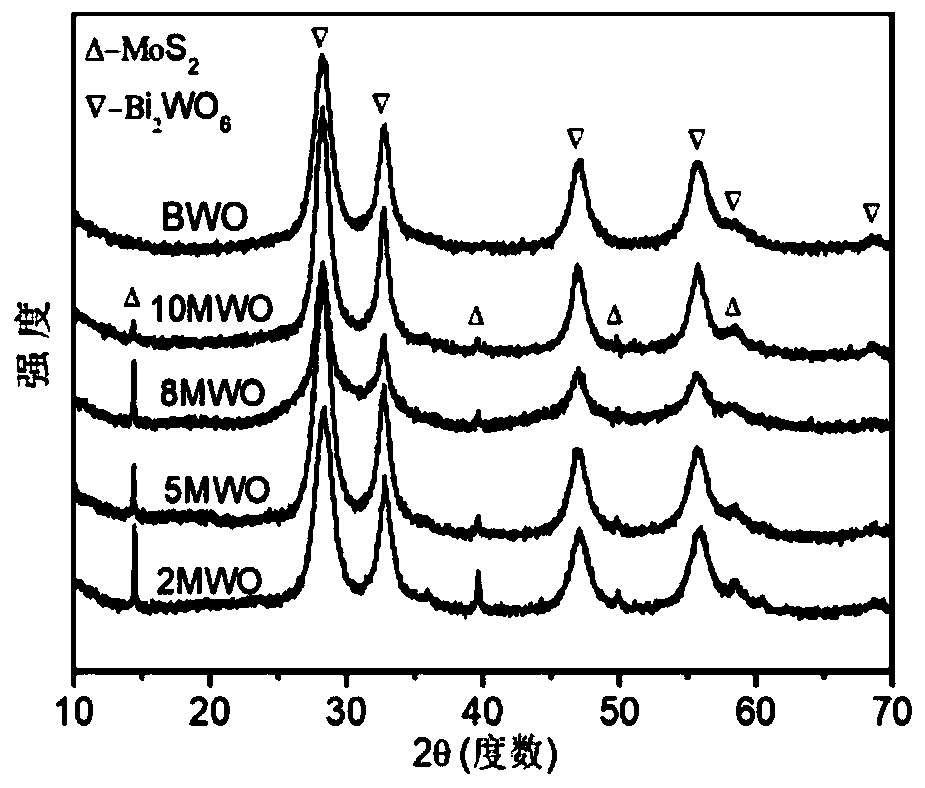

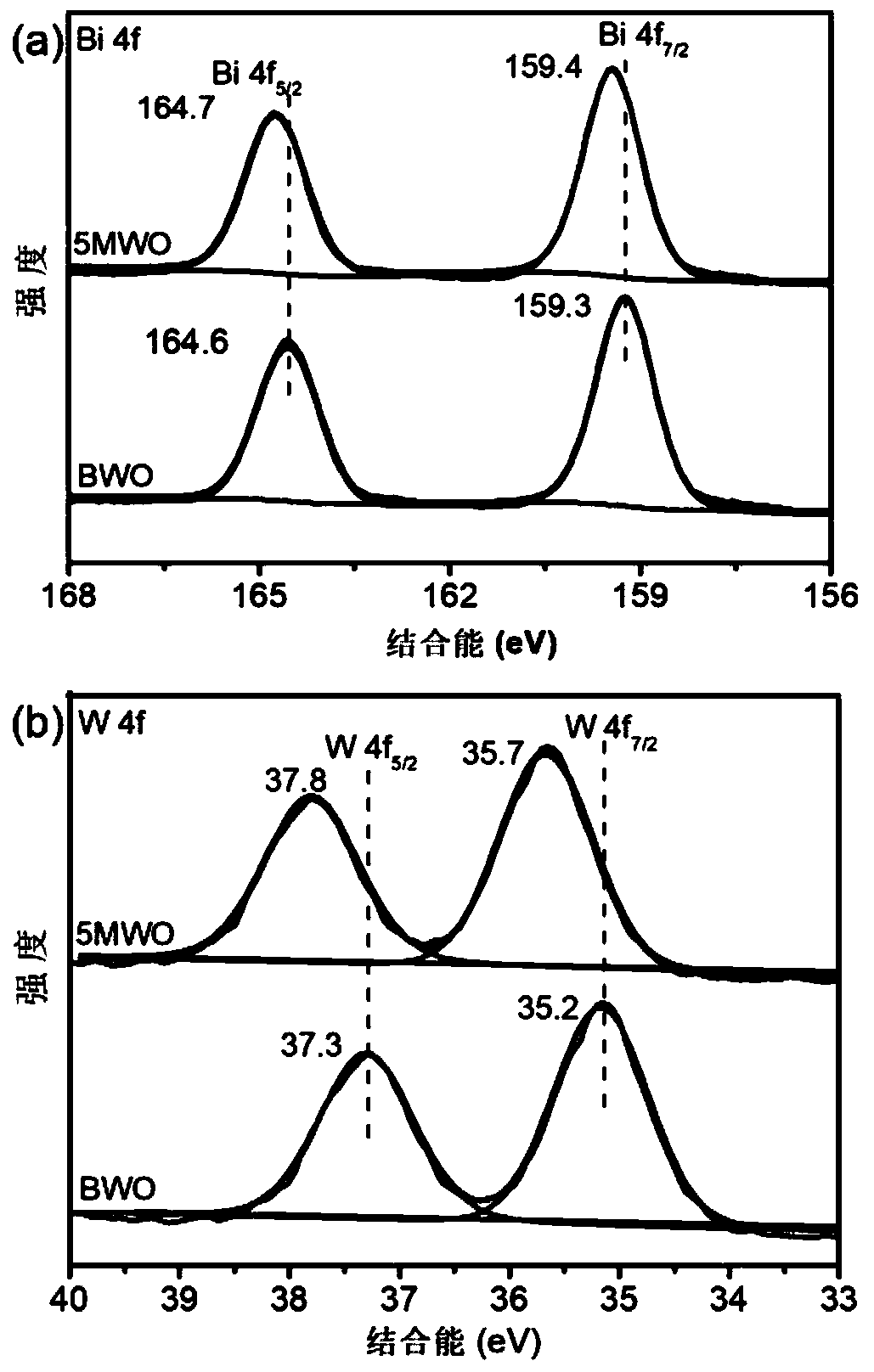

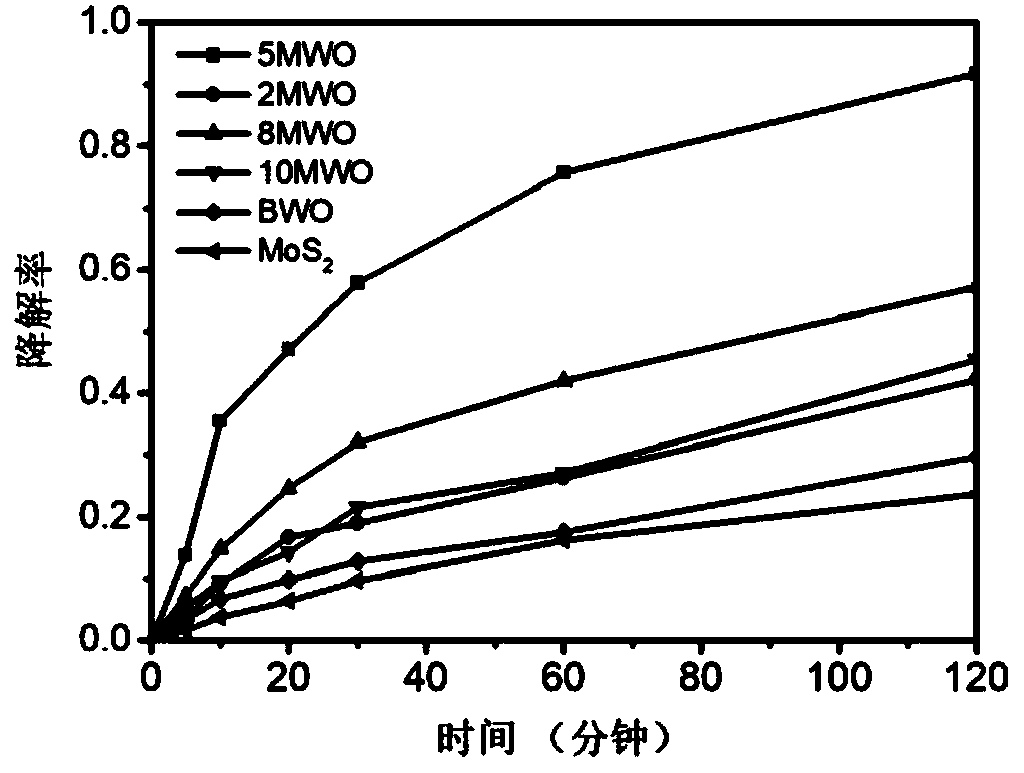

Method used

Image

Examples

Embodiment 1

[0027] A preparation method for photocatalytic degradation of VOCs catalyst, comprising the following steps:

[0028] Step 1, mix and dissolve PVP (1%) in 30ml ethylene glycol, stir magnetically until the dissolution is complete, then add 2.5mmolBi(NO 3 ) 3 ·5H 2 O continue to stir; at the same time 1mmolNa 2 WO 4 2H 2 O was dissolved in 20ml of ethylene glycol, and magnetically stirred until dissolved. the above Na 2 WO 4 2H 2 O was added dropwise to Bi(NO 3 ) 3 ·5H 2 O solution, magnetically stirred for 1 h, and mixed uniformly to obtain solution A.

[0029] Step 2, MoS 2 Prepared by hydrothermal method

[0030] 1.2g Na 2 MoO 4 2H 2 O and 1.6gNH 2 CSNH 2 Dissolve in 80ml of distilled water, stir for 1 hour, then put the solution into a polytetrafluoroethylene-lined autoclave with a hydrothermal temperature of 180°C and a hydrothermal time of 24 hours, separate the black precipitate by filtration at a speed of 10,000 rpm, and then use anhydrous Ethanol and ...

Embodiment 2

[0033]A preparation method for photocatalytic degradation of VOCs catalyst, comprising the following steps:

[0034] Step 1, mix and dissolve PVP (1%) in 30ml ethylene glycol, stir magnetically until the dissolution is complete, then add 2.5mmolBi(NO 3 ) 3 ·5H 2 O continue to stir; at the same time 1mmolNa 2 WO 4 2H 2 O was dissolved in 20ml of ethylene glycol, and magnetically stirred until dissolved. the above Na 2 WO 4 2H 2 O was added dropwise to Bi(NO 3 ) 3 ·5H 2 O solution, magnetically stirred for 1 h, and mixed uniformly to obtain solution A.

[0035] Step 2, MoS 2 Prepared by hydrothermal method, 1.2g of Na 2 MoO 4 2H 2 O and 1.6gNH 2 CSNH 2 Dissolve in 80ml of distilled water, stir for 1 hour, then put the solution into a polytetrafluoroethylene-lined autoclave with a hydrothermal temperature of 180°C and a hydrothermal time of 24 hours, separate the black precipitate by filtration, wash, and finally, dry and grind. The obtained product was dissolve...

Embodiment 3

[0039] A preparation method for photocatalytic degradation of VOCs catalyst, comprising the following steps:

[0040] Step 1, mix and dissolve PVP (1%) in 30ml ethylene glycol, stir magnetically until the dissolution is complete, then add 2.5mmolBi(NO 3 ) 3 ·5H 2 O continue to stir; at the same time 1mmolNa 2 WO 4 2H 2 O was dissolved in 20ml of ethylene glycol, and magnetically stirred until dissolved. the above Na 2 WO 4 2H 2 O was added dropwise to Bi(NO 3 ) 3 ·5H 2 O solution, magnetically stirred for 1 h, and mixed uniformly to obtain solution A.

[0041] Step 2, MoS 2 Prepared by hydrothermal method, 1.2g of Na 2 MoO 4 2H 2 O and 1.6gNH 2 CSNH 2 Dissolve in 80ml of distilled water, stir for 1h, then put the solution into a high-pressure Teflon-lined, hydrothermal temperature of 180°C, hydrothermal time of 24h, separate the black precipitate by filtration, wash, and finally, dry and grind to obtain The product was dissolved in ethylene glycol and sonicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com