Epoxy-modified alkyd resin, preparation method thereof, composition containing epoxy-modified alkyd resin and application of epoxy-modified alkyd resin

An alkyd resin and epoxy modification technology, which is applied in the field of radiation curing, can solve the problems of poor weather resistance, poor adhesion, and environmental pollution, and achieve the effects of good weather resistance, high adhesion, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

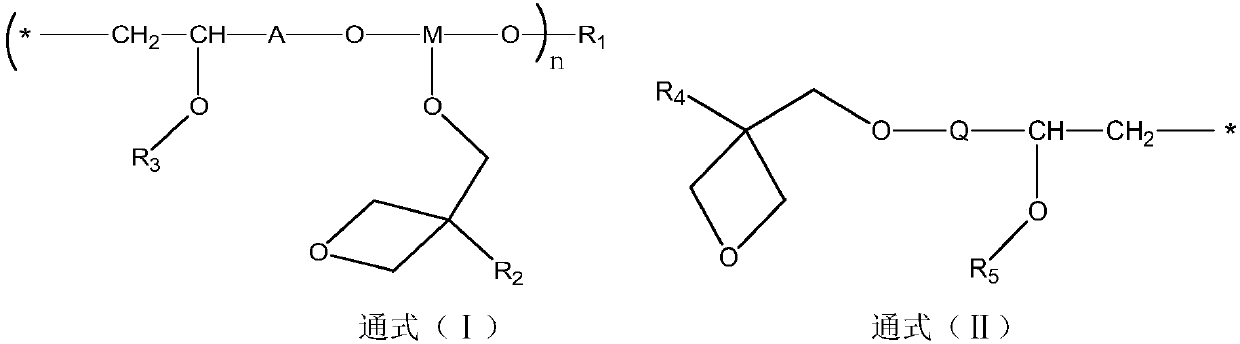

[0055] Method one: adopt alkyd resin as the first raw material, adopt the compound containing oxetane and oxirane shown in general formula (Ⅳ) or general formula (IV) as the second raw material, this preparation method comprises:

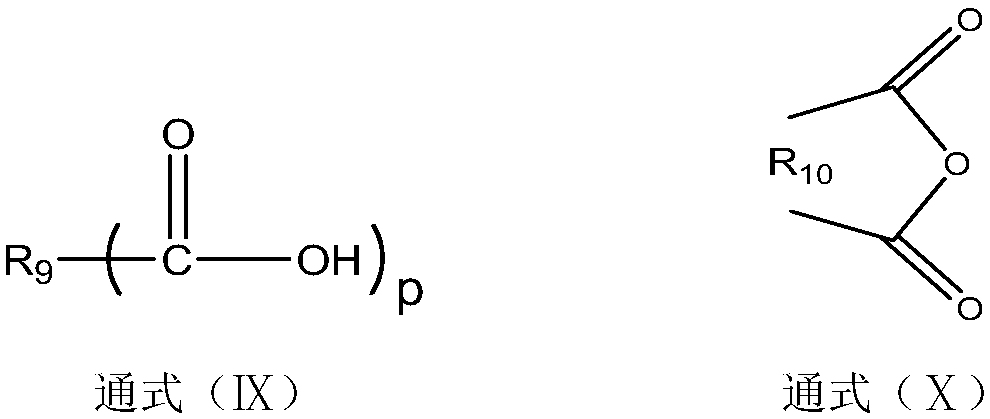

[0056] The hydroxyl group of the first raw material and the second raw material are subjected to ring-opening reaction of oxirane to obtain a hydroxyl-containing alkyd resin derivative; the hydroxyl group of the hydroxyl-containing alkyd resin derivative is subjected to a first end-capping compound reaction to obtain the epoxy-modified alkyd resin, the first capping compound is selected from acid anhydrides, acid halides, compounds containing oxirane, compounds containing oxetane or compounds containing double bonds, the general Formula (Ⅲ), the general formula (Ⅳ) respectively have the following structures:

[0057]

[0058] Among them, R 1 , R 2 , R 4 , A, M, Q and n have the definitions as defined above;

[0059] Method two: adopt alkyd re...

Embodiment 1

[0111] Reaction 1: Add 200g (containing about 0.17mol hydroxyl) alkyd resin (Huaqiu BDS3355, solid content: 55, hydroxyl value: 85, purchased from Guangde Bades Chemical Co., Ltd.), 20g (0.17mol) into a three-necked flask mol) of succinic acid, 4g of acidic cation exchange resin and 200mL of toluene, mixed evenly and heated to start the reaction, the reaction temperature was controlled at 120°C, and the reaction ended when the fractionated moisture was close to the theoretical moisture. Then, it was washed with saturated brine, concentrated under reduced pressure and bubbled, and filtered to obtain 120 g of intermediate 1 with an acid value of 75 mgKOH / g.

[0112] Reaction 2: Add 120g (containing about 0.16mol carboxyl group) intermediate 1, 1g triphenylphosphine and 28g (0.16mol) raw material 1 in a three-necked flask, react at 80°C for 8 hours, and filter to obtain 145g epoxy modified Alkyd resin.

[0113] Reaction 3: Add 145g (about 0.15mol of hydroxyl) of epoxy-modified a...

Embodiment 2

[0117] Reaction 1: Add 200g (containing about 0.21mol hydroxyl) alkyd resin (Huaqiu BDSTH3010-70, solid content: 70, hydroxyl value: 85, purchased from Guangde Bades Chemical Co., Ltd.), 25g into a three-necked flask (0.21mol) succinic acid, 5g acidic cation exchange resin and 200mL toluene, after mixing uniformly, heat to start reaction, control reaction temperature at 120 ℃, when the moisture that fractionation comes out is close to theoretical moisture, reaction ends. Then, it was washed with saturated brine, concentrated under reduced pressure and bubbled, and filtered to obtain 152 g of intermediate 2 with an acid value of 73 mgKOH / g.

[0118] Reaction 2: Add 152g (containing about 0.20mol carboxyl group) intermediate 2, 2g triphenylphosphine and 69g (0.20mol) raw material 2 in a three-necked flask, react at 80°C for 8 hours, and filter to obtain 216g epoxy modified Alkyd resin.

[0119] Reaction 3: Add 216g (containing about 0.19mol of hydroxyl groups) of epoxy-modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com