Energy-curable acrylic resin composition and application thereof

A technology of acrylic resin and composition, applied in the direction of modified epoxy resin adhesive, application, epoxy resin coating, etc., which can solve the problems of poor flexibility and adhesion of the coating, long curing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

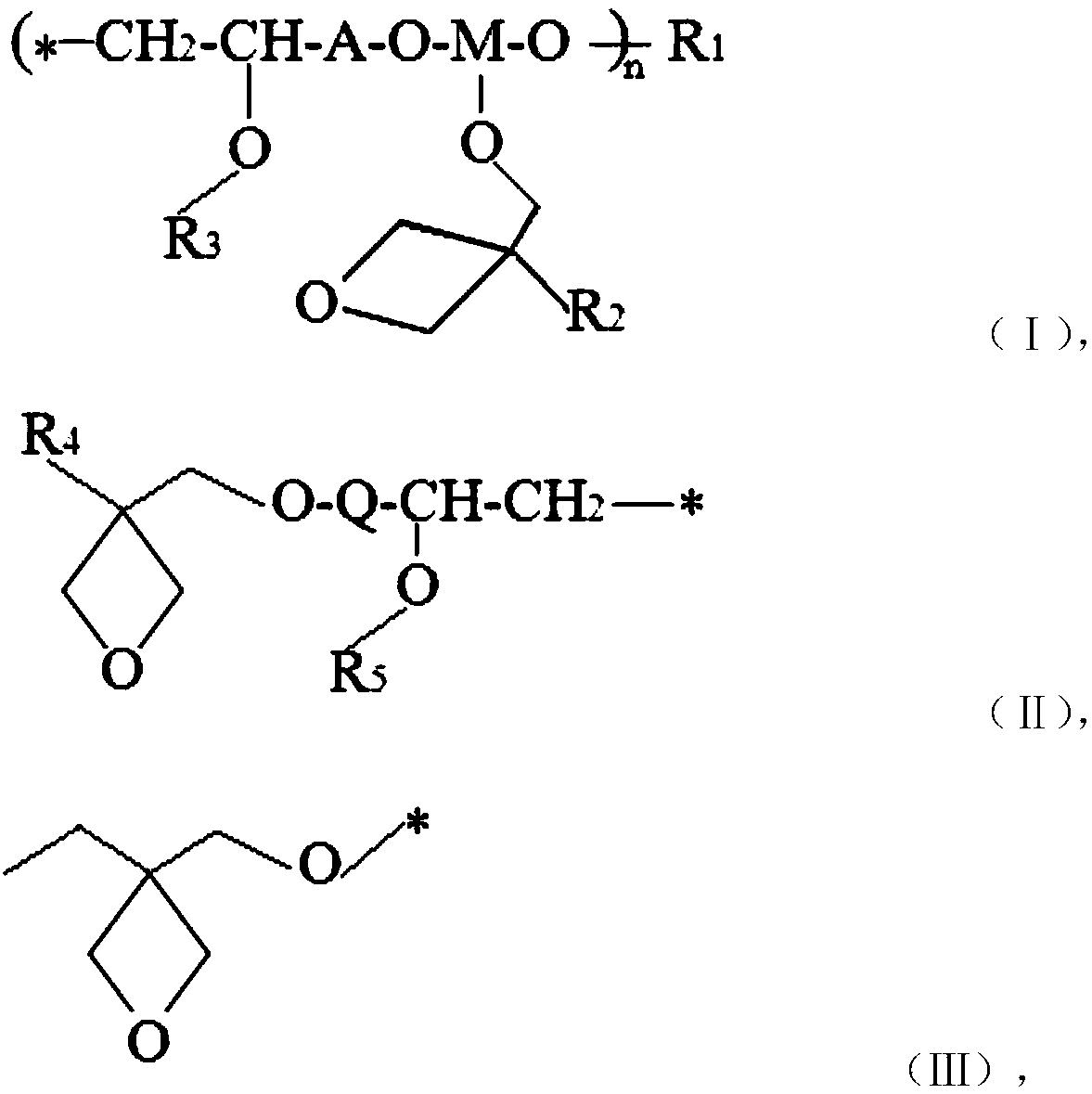

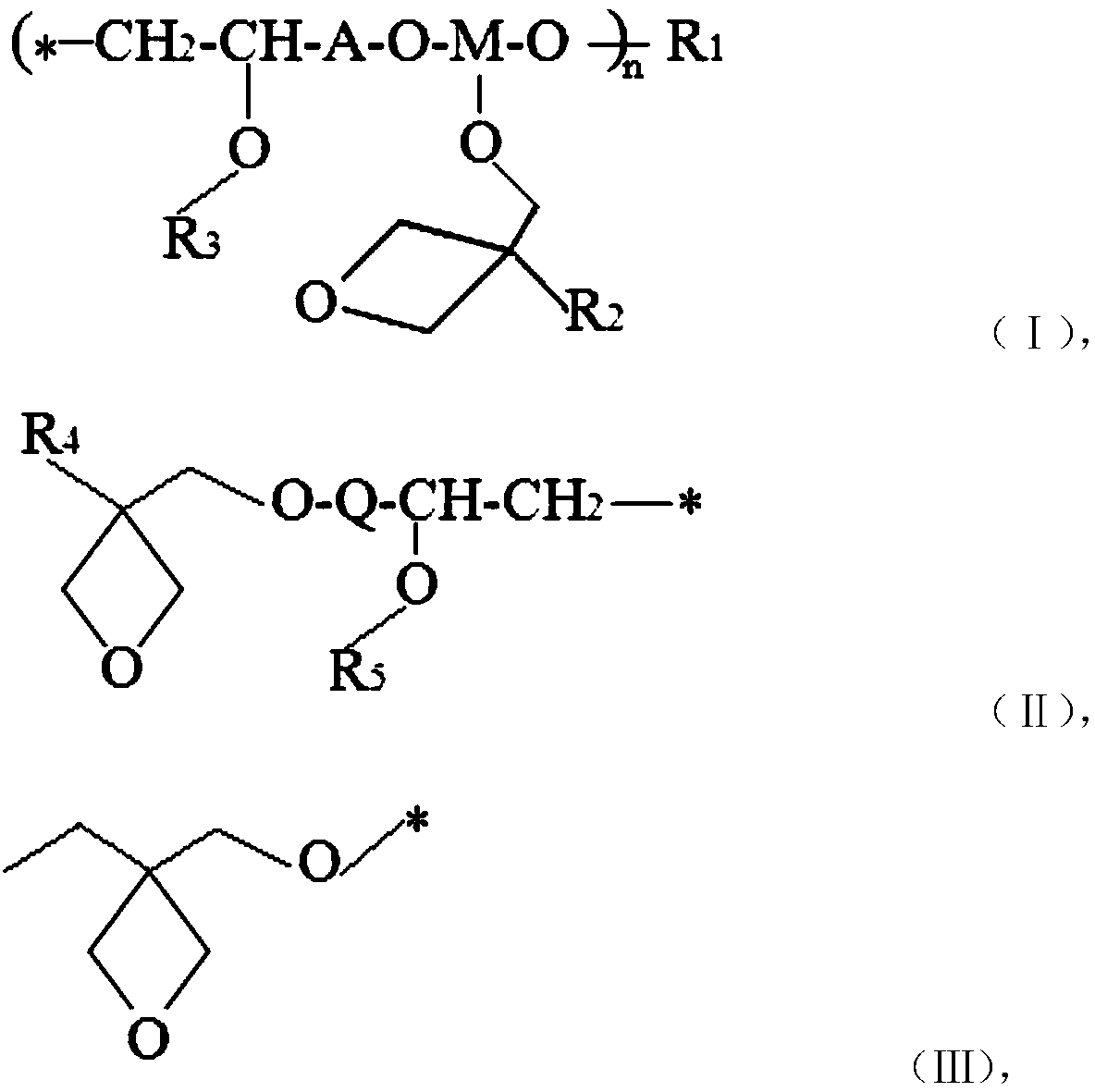

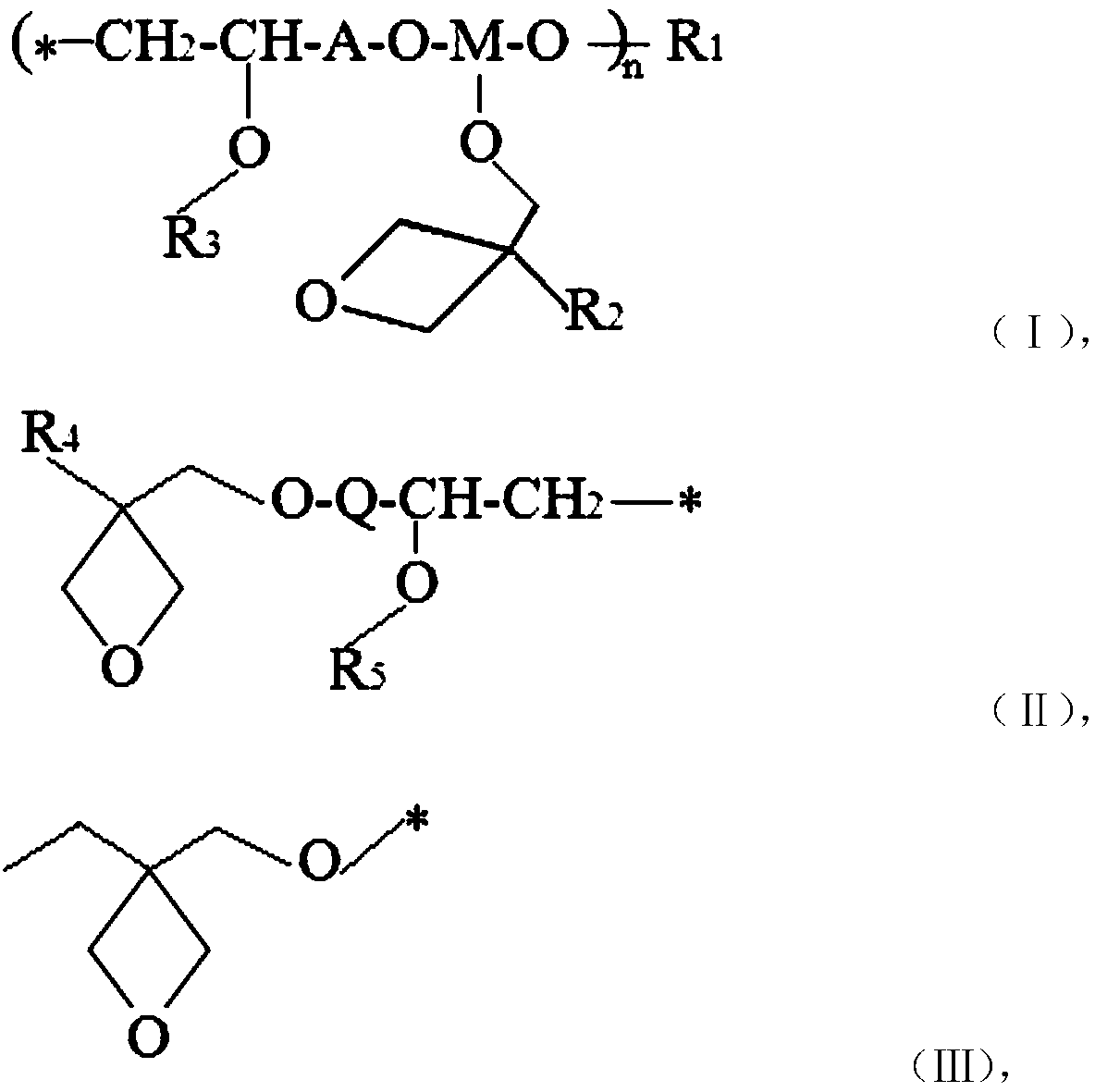

[0094] (1) Preparation of epoxy-modified acrylic resin

[0095] Preparation of starting materials 1-11:

[0096] Raw material 1:

[0097] Reaction: Add 58g (0.5mol) 3-hydroxymethyl-3-ethyloxetane, 46g (0.5mol) epichlorohydrin and 20g (0.5mol) sodium hydroxide successively in the three-necked flask, and React at 40°C for 12 hours, and follow the gas phase until the complete reaction of 3-hydroxymethyl-3-ethyloxetane. After the reaction was completed, it was washed with water, extracted, and distilled under reduced pressure to obtain 86 g of raw material 1.

[0098]

[0099] Raw material 2:

[0100] Reaction 1: Add 58g (0.5mol) 3-hydroxymethyl-3-ethyloxetane, 4g (0.1mol) sodium hydroxide and 100g toluene in sequence in a three-necked flask, stir and heat up to 80°C, drop Add 86g (0.5mol) of raw material 1, and drop it in 1.5h. Continue to stir the reaction, follow the gas phase until the content of 3-hydroxymethyl-3-ethyloxetane does not change, and stop heating. Adjust...

Embodiment 1

[0110] Reaction 1: Preparation of acrylic resin: Copolymerize with methacrylic acid monomer (MAA) and methyl methacrylate monomer (MMA) as raw materials: add 43g (0.5mol) of MAA and 200mL propylene glycol methyl into the reaction bottle Ether acetate, and heated to 60 ° C, and then the mixture of MMA 50g (0.5mol) and azobisisobutyronitrile 2.5g (3wt%) was slowly added dropwise to the reaction flask, and the feeding time was 0.5h. After the reactants were added, the reaction was continued for 6 h, and a white polymer precipitate was obtained. The above precipitate was filtered and dried to obtain 85 g of MAA-MMA acrylic resin.

[0111] Reaction 2: Add 100 g (containing 0.5 mol of carboxyl groups) MAA-MMA acrylic resin into a three-necked flask, add 500 mL of toluene, and heat to dissolve at 70° C. After dissolving, add 8g of triphenylphosphine and 170g (0.50mol) of raw material 2, react for 8h, extract, and distill under reduced pressure to obtain 250g of epoxy-modified acrylic ...

Embodiment 1-1

[0116] Reaction 1: Add 43g (0.5mol) of methacrylic acid monomer into a three-necked flask, add 200mL of toluene, and heat to dissolve at 70°C. After dissolving, add 6.5 g of triphenylphosphine and 170 g (0.50 mol) of raw material 2, react for 8 hours, extract, and distill under reduced pressure to obtain 200 g of intermediate 1.

[0117] Reaction 2: Add 85g (0.2mol) of intermediate 1, 21g (0.2mol) of isobutyryl chloride, 200mL of toluene and 10g of sodium hydroxide to a three-necked flask in sequence, and react at 40°C for 12h. After the reaction, wash with water, extract, and reduce Pressure distillation afforded 95 g of intermediate 2.

[0118] Reaction 3: Preparation of acrylic resin: add 245g (0.5mol) of intermediate 2 and 500mL of propylene glycol methyl ether acetate into the reaction bottle, preheat to 60°C, add 50g (0.5mol) of MMA and 9g of azobisisobutyronitrile (3wt%) mixed and slowly added dropwise to the reaction flask, the feeding time is about 0.5h. Continue to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com