A kind of sulfur quantum dot/manganese dioxide nanosheet composite material and its preparation method and application

A manganese dioxide and composite material technology, applied in the field of nano-analysis, can solve the problems of low detection sensitivity of BchE, toxicity of detection materials and reagents, etc., and achieve the effects of strong anti-interference ability, low biological toxicity and wide detection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Mix 2.5 μL of sulfur quantum dot solution with 14 μL of manganese dioxide nanosheet aqueous solution, add deionized water to make the total volume of the system 60 μL, so that the concentration of sulfur quantum dots is 6.67 mg / mL, and the concentration of manganese dioxide nanosheets is 163.3 μg / mL, using NaOH aqueous solution to adjust the pH of the mixed solution to 7.1, and reacting at 30 °C for 1 hour to obtain the sulfur quantum dot / manganese dioxide nanosheet composite material.

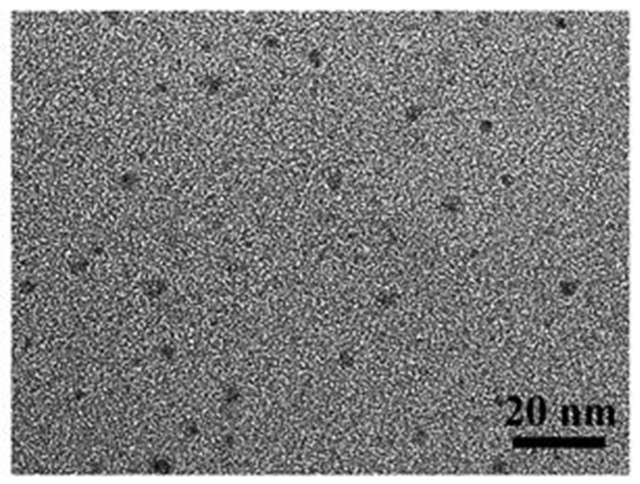

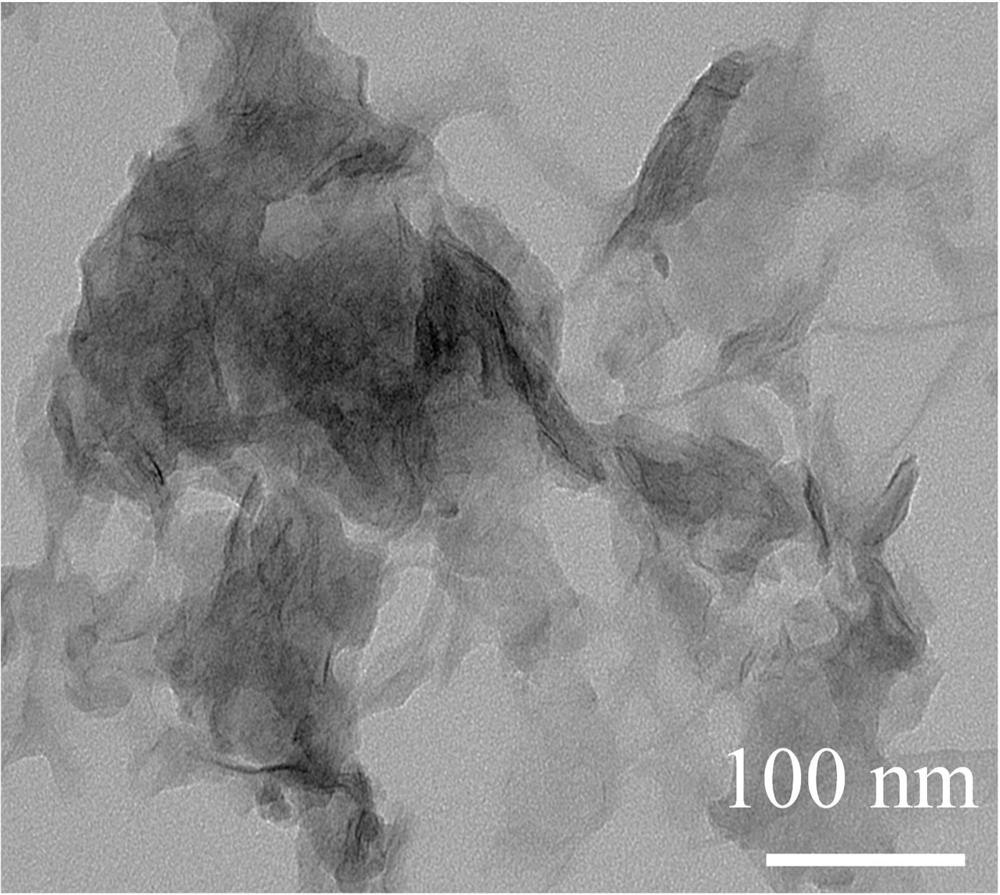

[0072] After the obtained product was ultrasonically dispersed and mixed in a certain proportion, it was dropped on a copper mesh, and then air-dried naturally. The sulfur quantum dots / manganese dioxide nanosheet composites were characterized by TEM-Mapping, and the obtained results were as follows: Figures 5~8 shown. It can be seen from the figure that the sulfur quantum dots / manganese dioxide nanosheet composites were successfully synthesized, and the sulfur quantum dots were uniform...

Embodiment 2

[0074] Mix 2.5 μL sulfur quantum dot solution with 14 μL manganese dioxide nanosheet aqueous solution, add deionized water to make the total volume of the system 60 μL, so that the concentration of sulfur quantum dots is 4 mg / mL, and the concentration of manganese dioxide nanosheets is 163.3 μg / mL, adjust the pH of the mixed solution to 7.1, and react at 30 °C for 1 hour to obtain the sulfur quantum dot / manganese dioxide nanosheet composite material.

Embodiment 3

[0076] Mix 2.5 μL of sulfur quantum dot solution with 14 μL of manganese dioxide nanosheet aqueous solution, add deionized water to make the total volume of the system 60 μL, so that the concentration of sulfur quantum dots is 6.67 mg / mL, and the concentration of manganese dioxide nanosheets is 116.7 μg / mL, adjust the pH of the mixed solution to 7.1, and react at 30 °C for 1 hour to obtain the sulfur quantum dot / manganese dioxide nanosheet composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com