Three-layer all-dielectric rectangular grating for realizing -2 level broadband high efficiency

A rectangular grating, all-dielectric technology, applied in the field of three-layer all-dielectric rectangular grating, to achieve the effects of mature technology, small aspect ratio and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

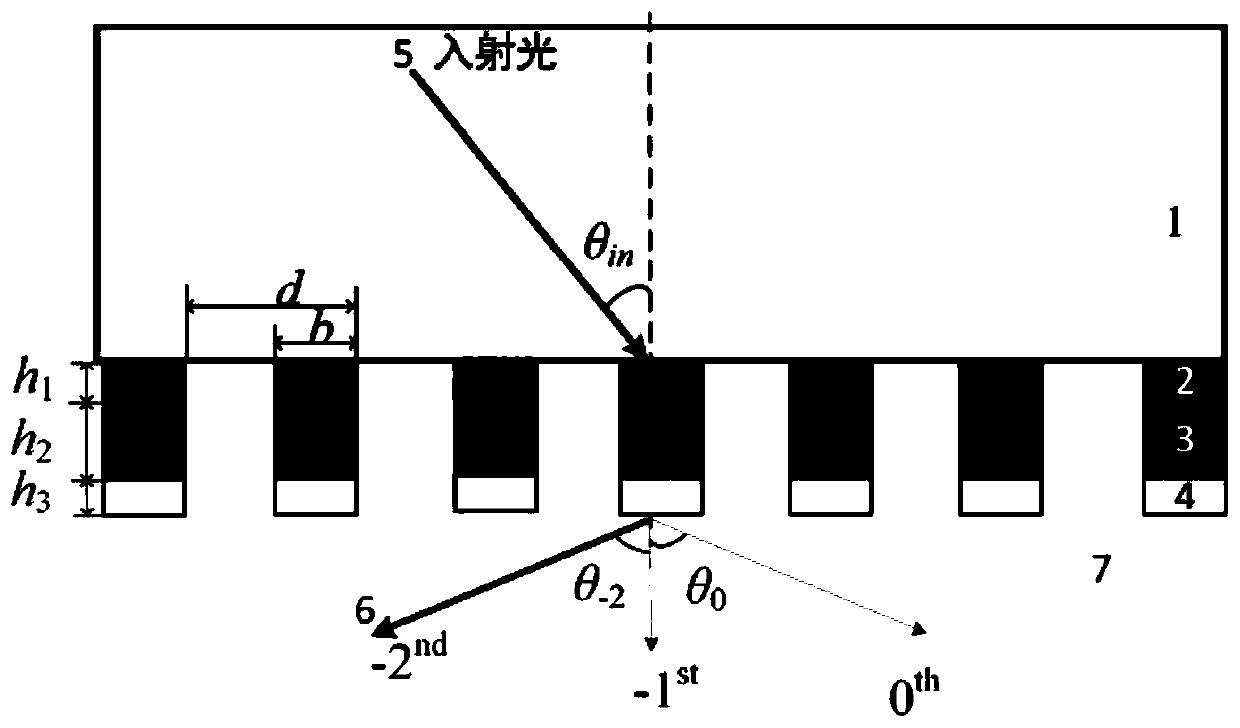

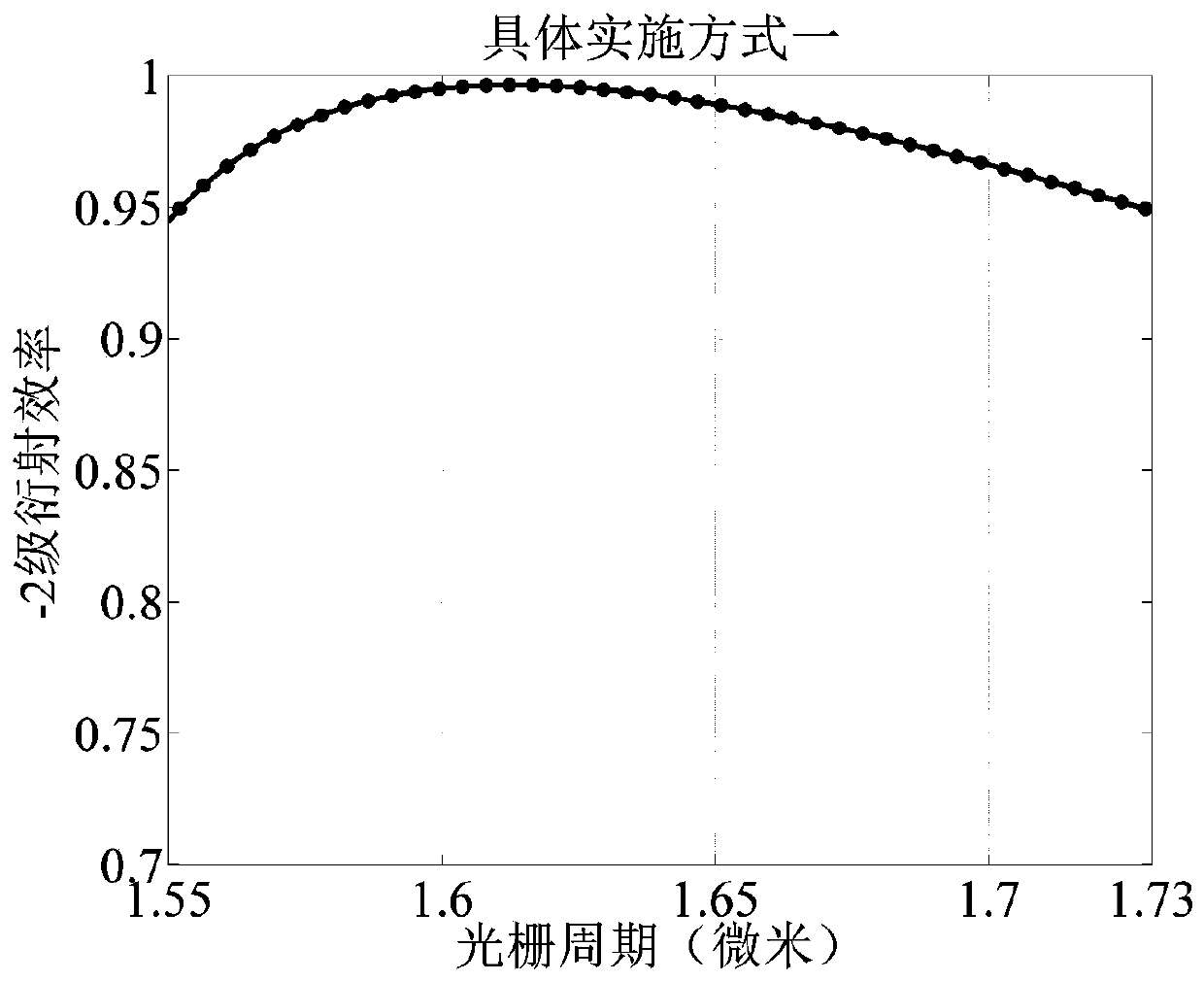

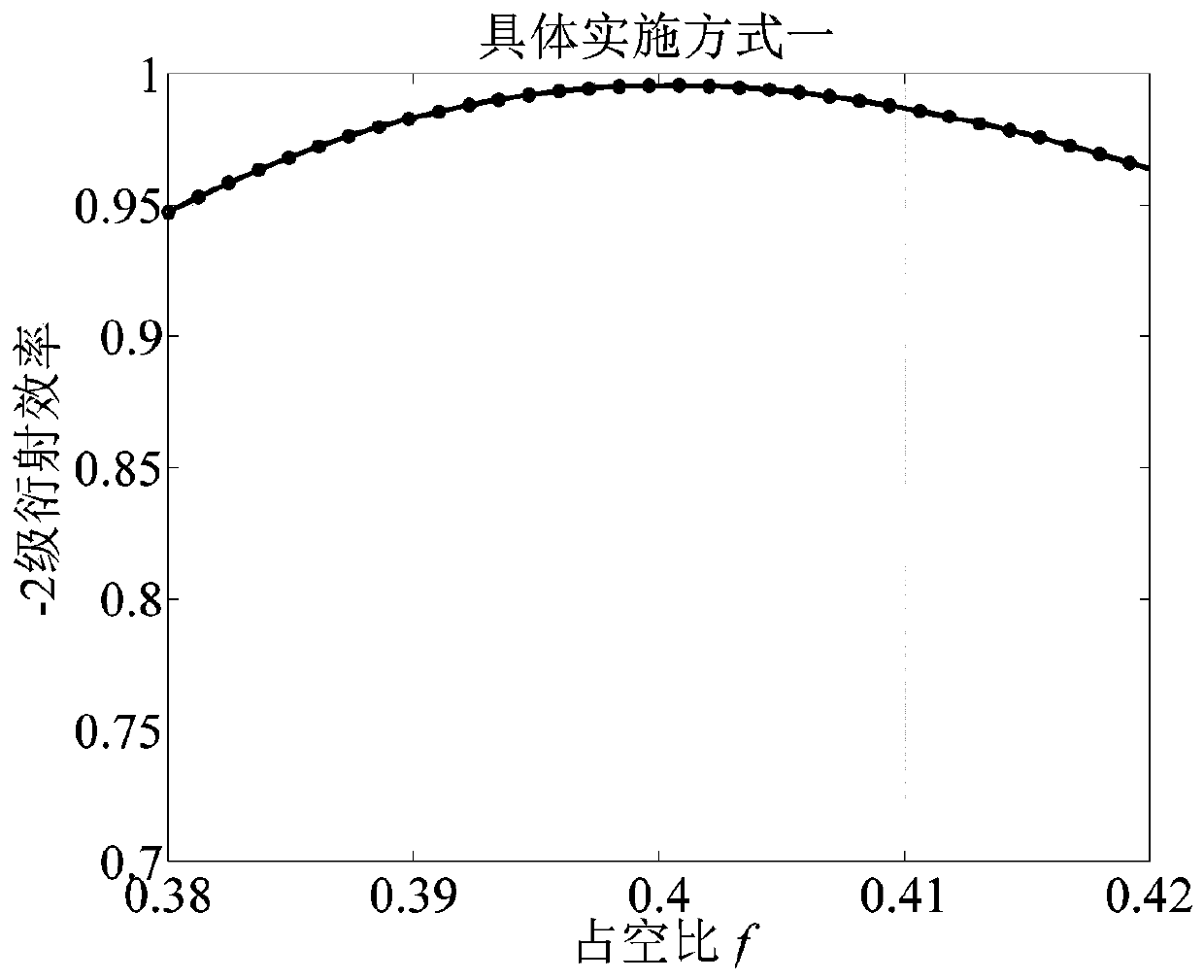

[0034] see first figure 1 , figure 1 It is a schematic diagram of a negative secondary high-efficiency three-layer all-dielectric rectangular grating in the 1.5 micron band of the present invention, in the figure: θ in represents the angle of incidence, θ -2 , θ 0 are the diffraction angles of -2 order and 0 order respectively, h 1 、h 2 and h 3 are the layer thicknesses of aluminum oxide, titanium dioxide and silicon dioxide in the three-layer all-dielectric rectangular grating structure, respectively. b represents the width of the grating ridge, and d represents the grating period (the duty cycle is f=b / d). Areas 1, 2, 3, 4, and 7 are homogeneous media. The grating vector K is located in the incident plane, the vibration direction of the TE polarized light corresponding to the electric field vector is perpendicular to the incident plane, and the TE polarized light is at a certain angle θ in =arcsin(λ / n 1 d) (defined as the quadratic Bragg angle) incident on the grati...

specific Embodiment approach 2

[0038] Due to different wavelengths, the corresponding refractive index of the material is also different. The three-layer structure is re-optimized below, and the grating structure is still used figure 1 Structure, re-optimize the structural parameters, when the grating duty cycle is 0.4263, the period is 0.8647 microns, and the depth h 1 184.2 nm, h 2 506 nm, h 3 When it is 186.1 nanometers, the effect is the best. Figure 9 , Figure 10 , Figure 11 , Figure 12 with Figure 13 , are the control variables for the duty cycle, duty cycle f, h1, h2, and h3 respectively, and study the influence of its tolerance on the value of the -2 order diffraction efficiency. It can be seen that for each parameter variable, the diffraction efficiency output of more than 95% can be achieved within a large tolerance range. For the diffraction efficiency above 95% is the standard, the tolerance intervals are, period (833.9-924.2 nanometers), duty cycle (0.4076-0.4494), h1 (113.9-257.9 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com