Predicting method for chamfering tool machined fiber-reinforced composite material burr length

A technology of chamfering tools and composite materials, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as inapplicable models, and achieve the effect of saving tool and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] In this embodiment, a grinding wheel is used to carry out experiments, that is, the chamfering tool is a grinding wheel with chamfering, to further illustrate and verify the reliability of the method of the present invention.

[0092] A method for predicting the burr length of fiber-reinforced composite materials with a chamfering tool, comprising the following steps:

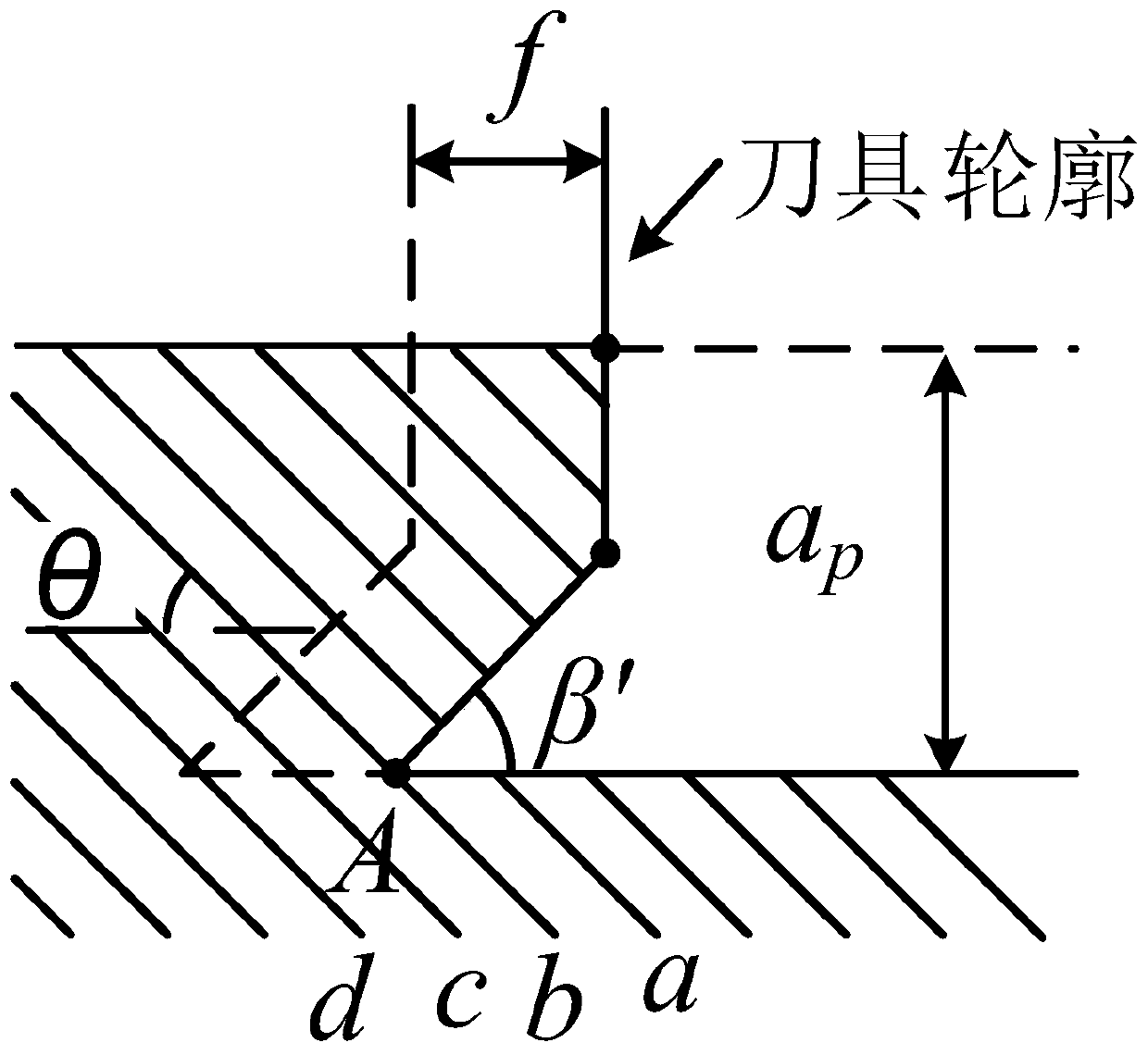

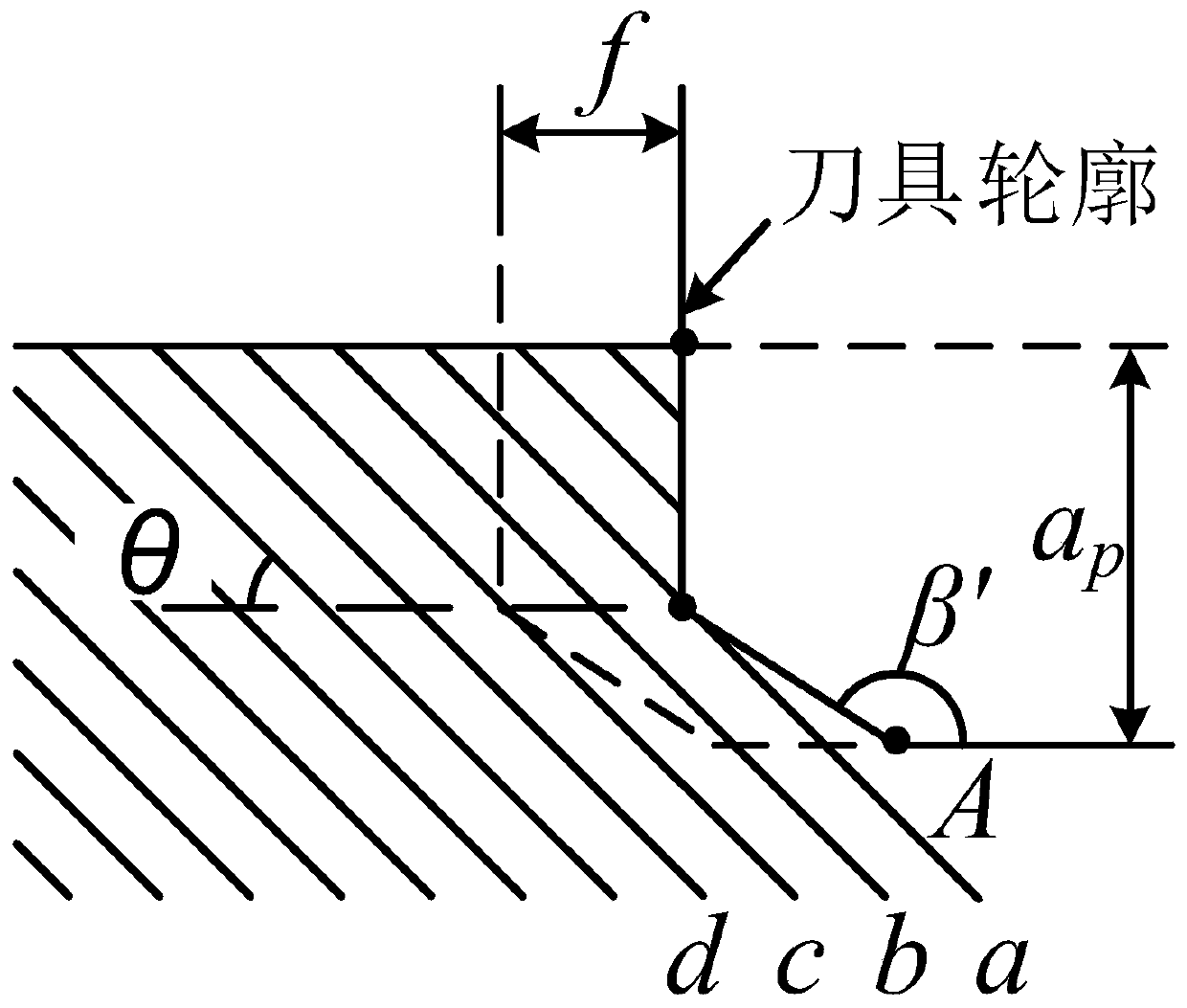

[0093] Step 1: Measure the chamfering angle β and chamfering length b of the chamfering grinding wheel ∈ and grinding wheel end face radius r s , Figure 4 It is a schematic diagram of the relative dimensions of the chamfering wheel geometry. The measured chamfering angle of the chamfering grinding wheel β=132°, the chamfering length b ∈ =1.5mm, grinding wheel end face radius r s 20mm.

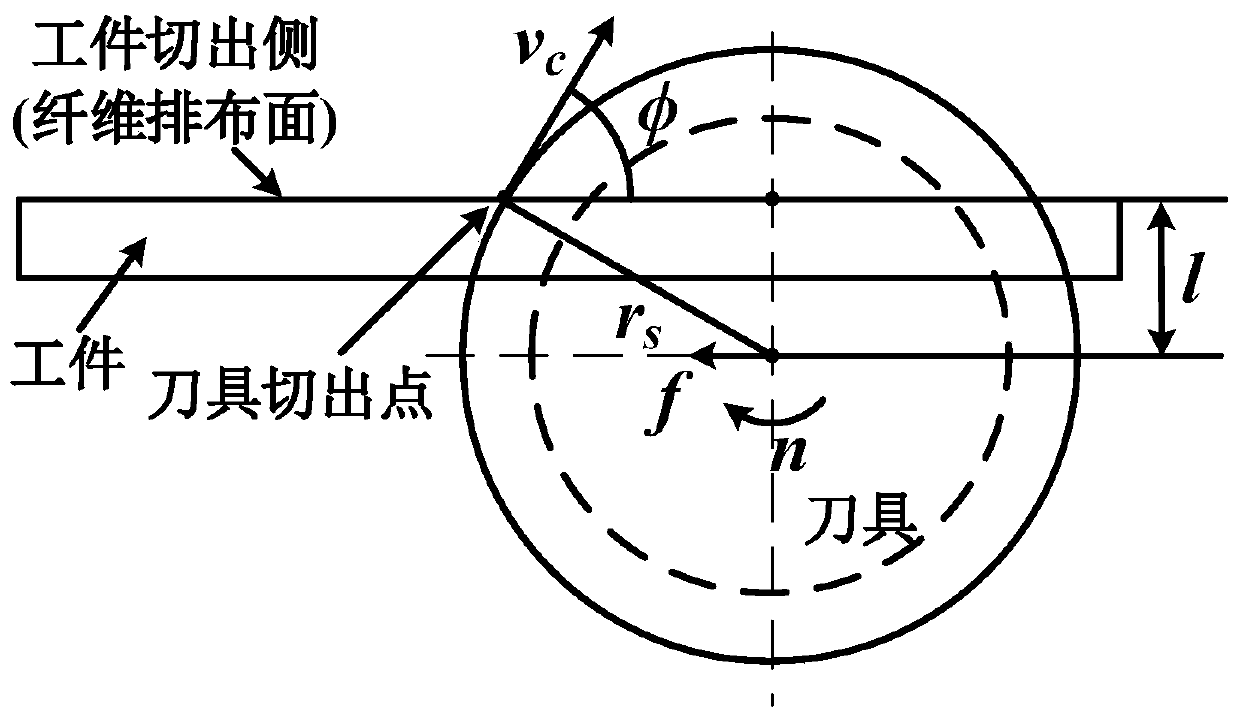

[0094] The second step: establish the tool-workpiece contour geometric model, and set up the single-factor experiment according to the calculation results of the cutting angle φ. The single-factor experiment paramet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com