Calcification resistance control method and system for anaerobic treatment of high-calcium organic wastewater

A technology for organic wastewater and anaerobic treatment, applied in aerobic and anaerobic process treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of increased calcified sand particles mixed with sludge, high cost and installation cost, Problems such as pipeline scaling and blockage, to achieve the effect of preserving sludge particle size, reducing crushing, and enhancing buffering capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

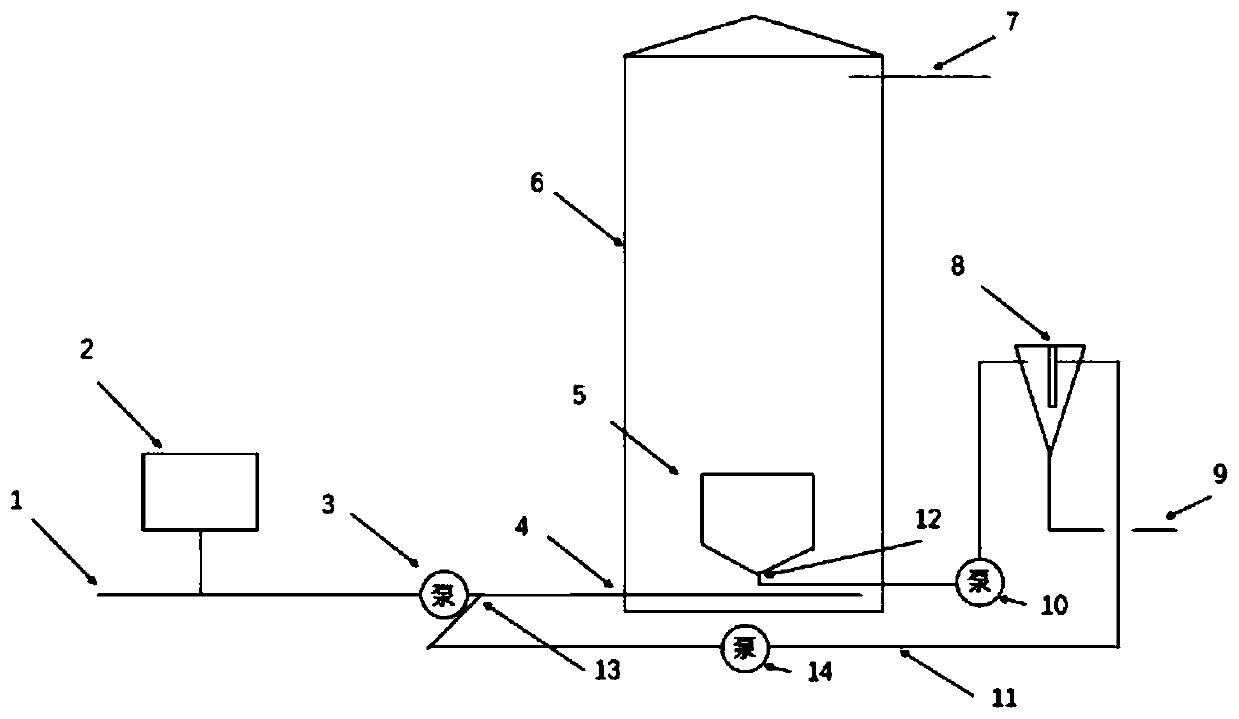

Method used

Image

Examples

example 1

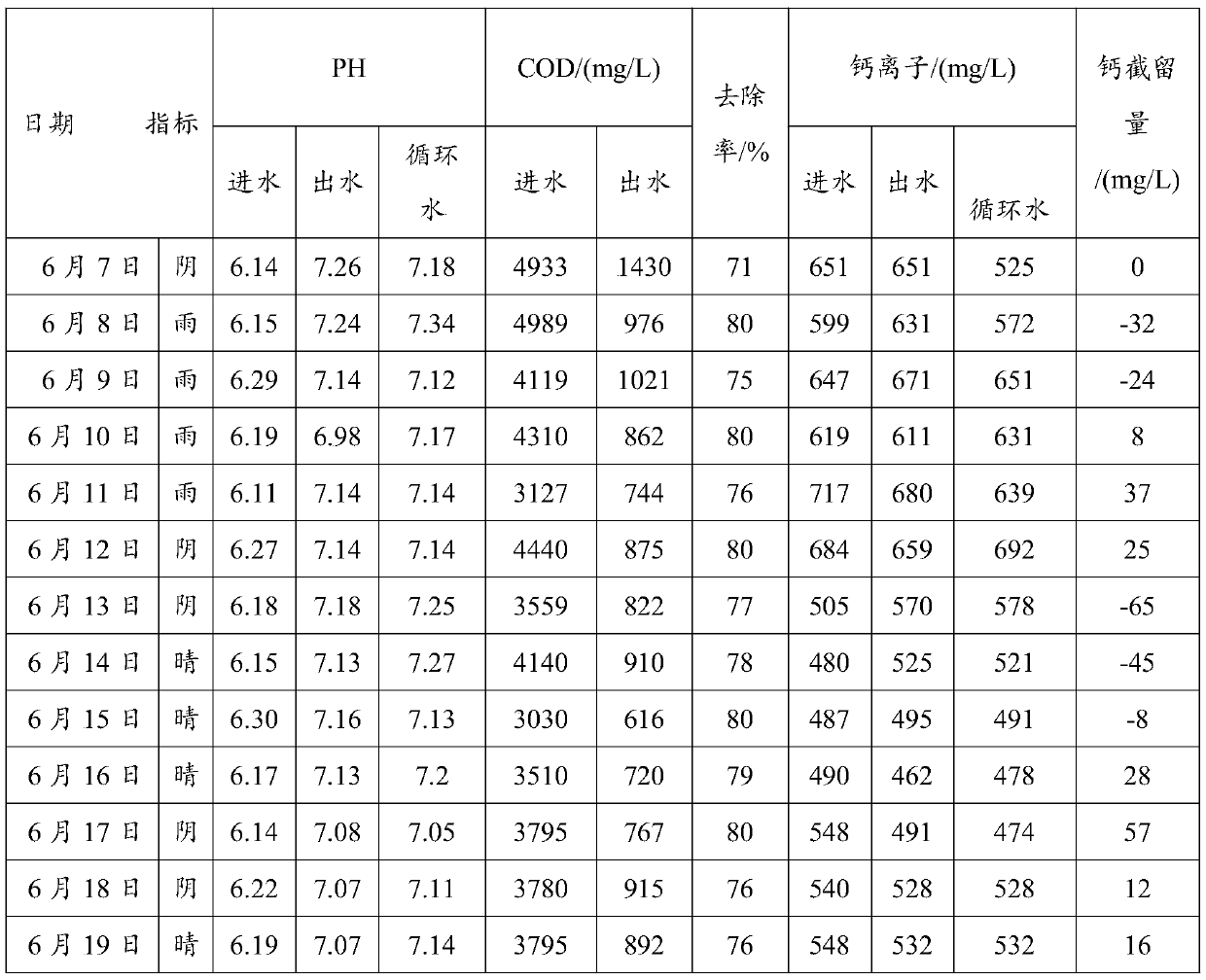

[0037] A recycled paper and papermaking enterprise in northern Guangdong, Guangdong, has an average daily sewage discharge of 1,000 tons, wastewater COD concentration of 4500mg / L, calcium ion concentration of 900mg / L, and wastewater pH of about 6.2 before entering the system. In June 2019, phosphoric acid and disodium hydrogen phosphate were added during the pre-acidification to the anaerobic tower, and the dosage of 85% phosphoric acid was 0.025kg / m 3 , the dosage of disodium hydrogen phosphate is 0.045kg / m 3 , the converted mass ratio of phosphoric acid to disodium hydrogen phosphate is about 2.12, and the ratio of molar concentration of calcium ions to molar concentration of phosphate is 43:1; the test data are shown in Table 1.

[0038] Table 1

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com