Method for extracting and separating polysaccharide from codium fragile

A technology of pine algae and polysaccharides, applied in the direction of antiviral agents, etc., can solve the problems of difficult separation and low extraction rate of polysaccharides, and achieve the effect of large adsorption capacity, low viscosity of slurry, and easy filtration and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Dried P. chinensis at 40°C and crushed through a 60-mesh sieve for later use. Take pine algae powder, degrease by 85% ethanol reflux for 2 h, repeat twice, and then dry to obtain degreasing pine algae powder. Then carry out the treatment of destroying the cell wall: heat a small amount of water to 50 ° C, add 100 g of defatted pine algae powder and stir, add water in batches until the defatted pine algae powder just dissolves, mix 0.5 g of fatty acid ether sodium sulfate and 5 g of polysorbate- 80 was dissolved in ethanol whose volume was 5% of that of water, and the ethanol solution was added to the aqueous solution of degreased pine algae powder, stirred vigorously for 2 hours, centrifuged to obtain the water phase, filtered to obtain the filter cake, and dried for later use;

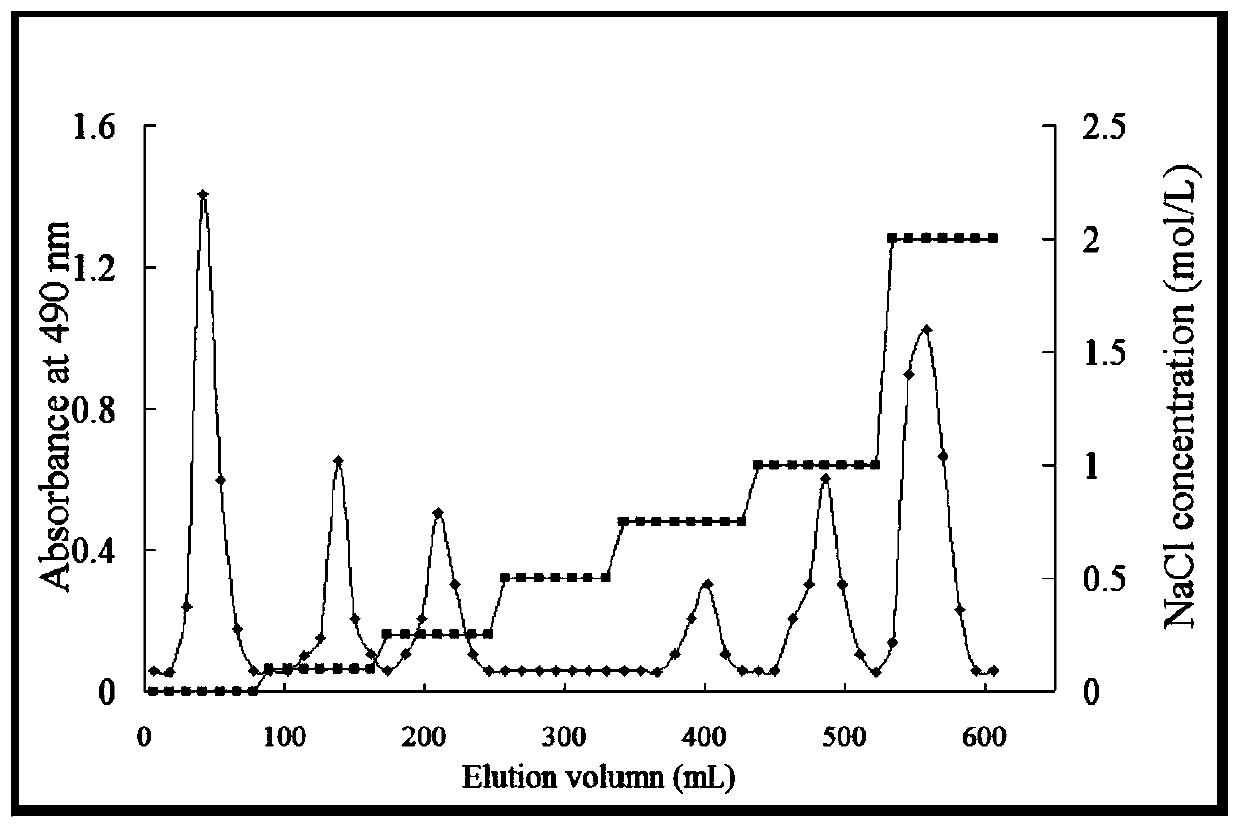

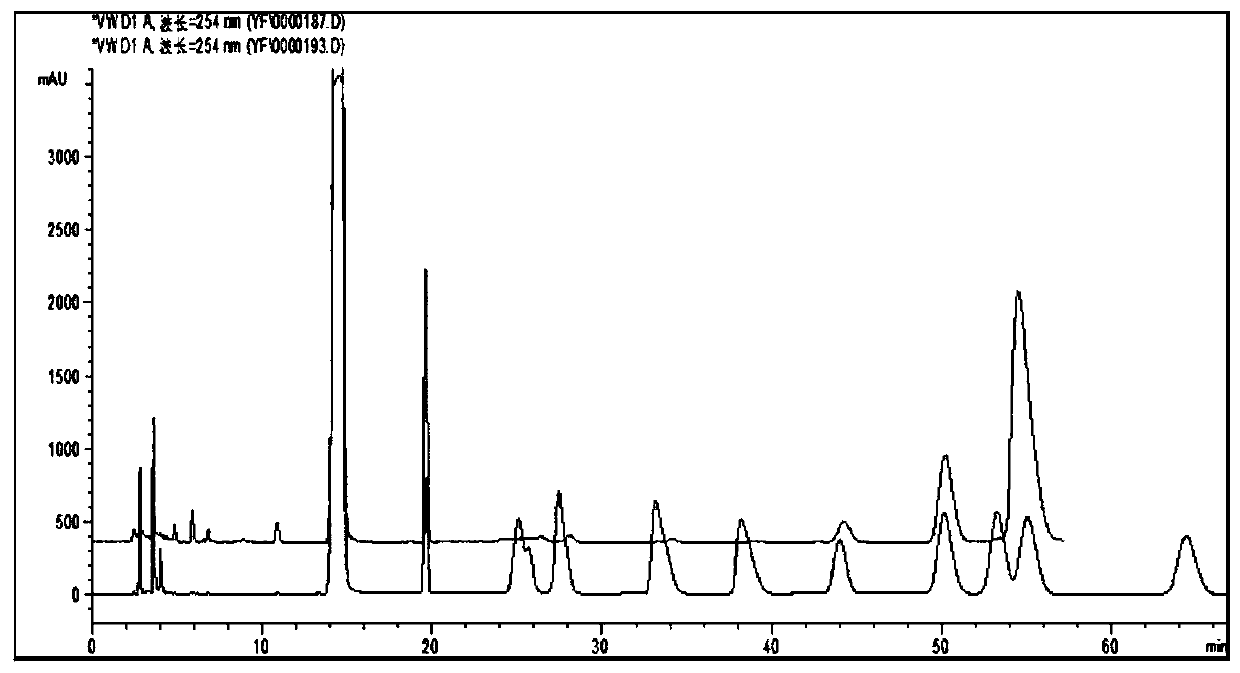

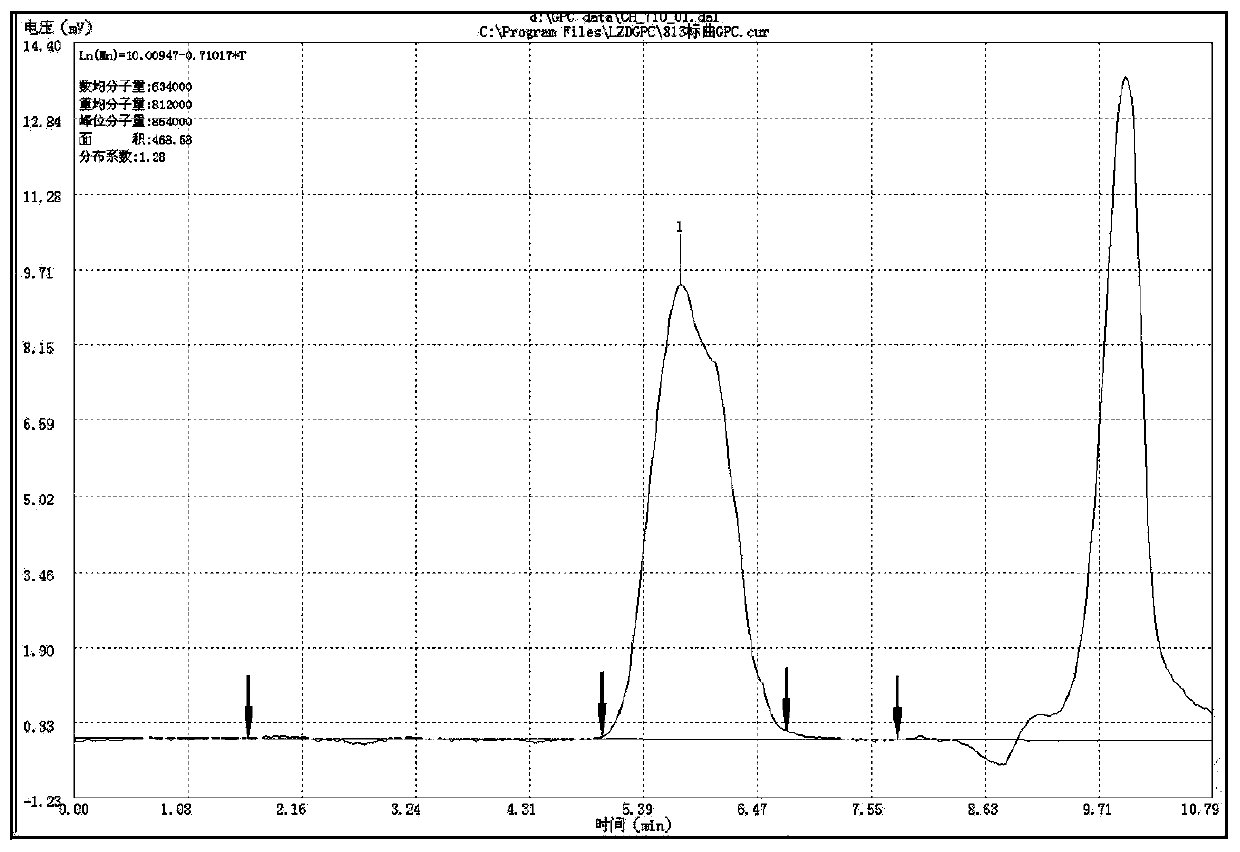

[0024] 2) Add about 20 times the volume of water to the dried pine algae, stir and extract with an electronic mixer in a water bath at 100 °C for 2 h, centrifuge, repeat the extraction of th...

Embodiment 2

[0031] 1) Take the degreased pine algae powder of Example 1, and carry out the treatment of destroying the cell wall: heat a small amount of water to 70°C, add 100g of the defatted pine algae powder and stir, add water in batches until the defatted pine algae powder just dissolves, and 2 1 g of fatty acid ether sodium sulfate and 3 g of polysorbate-80 were dissolved in ethanol whose volume was 20% of that of water, and the ethanol solution was added to the aqueous solution of degreased pine algae powder, stirred vigorously for 3 h, centrifuged to obtain the water phase, and filtered to obtain the filter cake , dry for later use;

[0032] 2) Add about 30 times the volume of water to the dried pine algae, stir and extract with an electronic mixer in a water bath at 80°C for 4 hours, centrifuge, repeat the extraction of the algae residue twice, combine the supernatants to concentrate and alcohol precipitation, and place in a refrigerator at 9°C Stand in the middle overnight, filt...

Embodiment 3

[0036] Take the degreased pine algae powder of Example 1, and carry out the treatment of destroying the cell wall: heat a small amount of water to 60 ° C, add 100 g of the defatted thorn pine algae powder and stir, add water in batches until the defatted thorn pine algae powder just dissolves, and 1 g Fatty acid ether sodium sulfate and 4 g polysorbate-80 were dissolved in ethanol whose volume was 10% of the volume of water, and the ethanol solution was added to the aqueous solution of degreased pine algae powder, stirred vigorously for 3 h, centrifuged to obtain the water phase, filtered to obtain the filter cake, Dry and reserve;

[0037] 2) Add about 20 times the volume of water to the dried pine algae, stir and extract with an electronic mixer in a water bath at 90 °C for 1 h, centrifuge, repeat the extraction of the algae residue twice, combine the supernatants to concentrate and alcohol precipitation, and store in a refrigerator at 3 °C Stand in the middle overnight, fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com