Solid-liquid phase change energy storage device for separately-filled molten salt

An energy storage device, solid-liquid phase change technology, applied in heat exchanger types, heat storage equipment, lighting and heating equipment, etc. The energy temperature should not be too high, etc., to achieve high thermoelectric conversion efficiency, reduce heat loss, and simple heat release method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments.

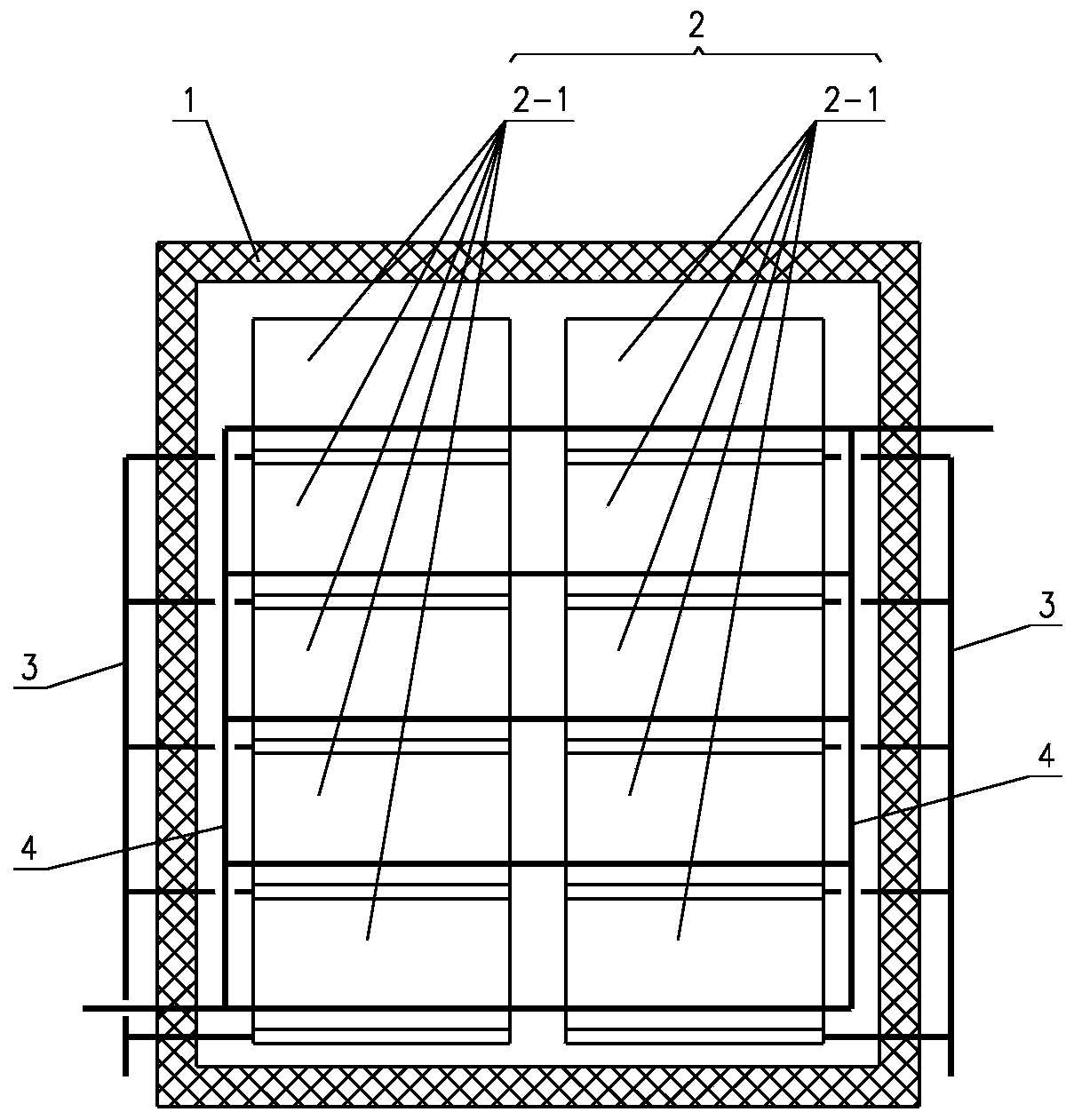

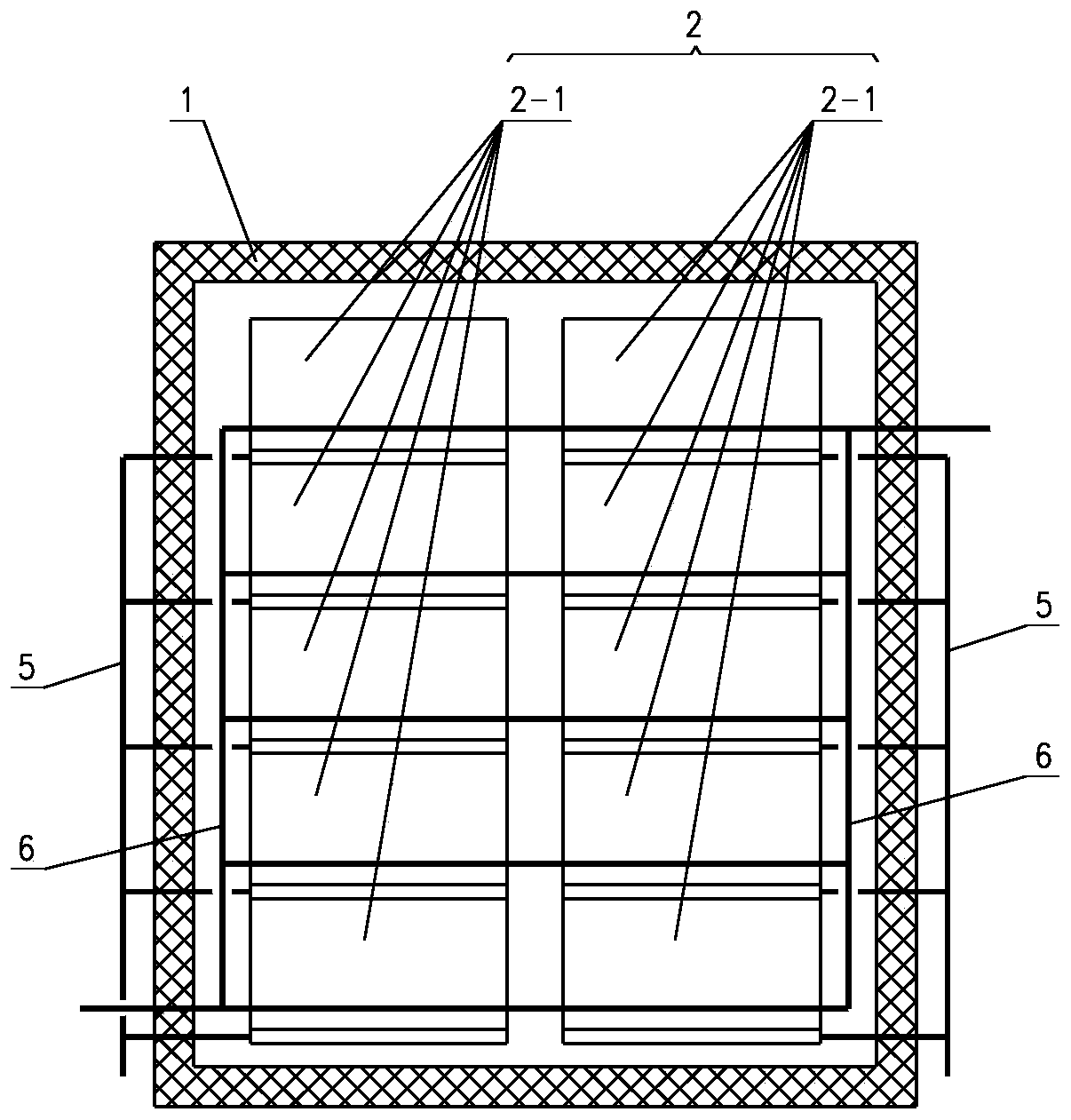

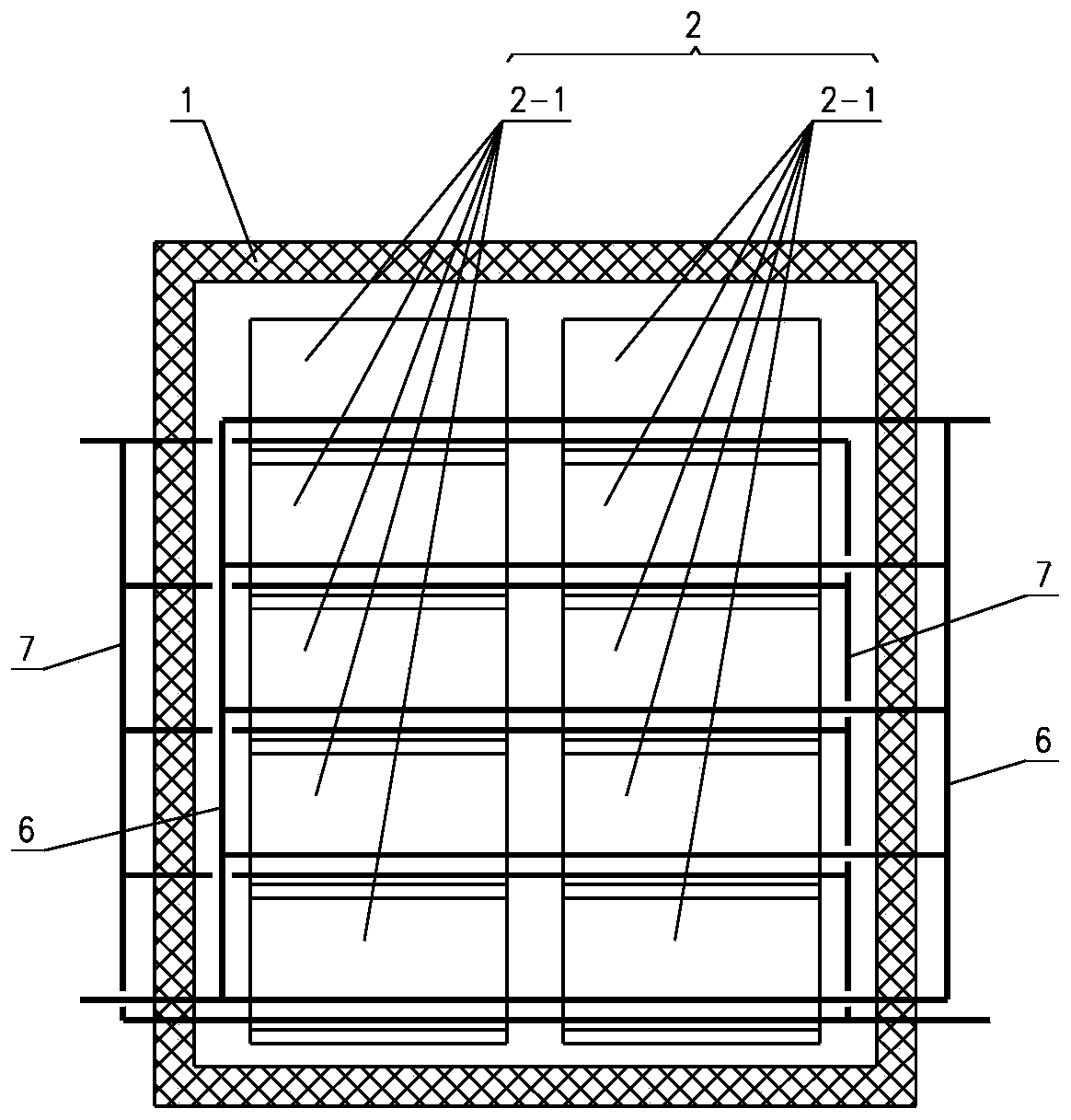

[0051] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, a solid-liquid phase change energy storage device for dispersed filling molten salt, including a thermal insulation shell 1, an energy storage body 2, a heat storage circuit 3, and a heat release circuit 4. The energy storage body 2 is arranged in the thermal insulation shell 1, and the energy storage body 2 is formed by stacking several energy storage body units 2-1, and the energy storage body unit 2-1 is filled in the The molten salt 2-1-2 in the molten salt box 2-1-1 is composed of heat storage circuit 3 and heat release circuit 4 and several energy storage units 2-1, the purpose of which is to store heat Heat energy is transferred between the heating working medium in the circuit 3 and the heat releasing working medium in the heat releasing circuit 4 and the energy storage unit 2-1.

[0052]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com