High-speed wavelength tuning laser made of lithium niobate material

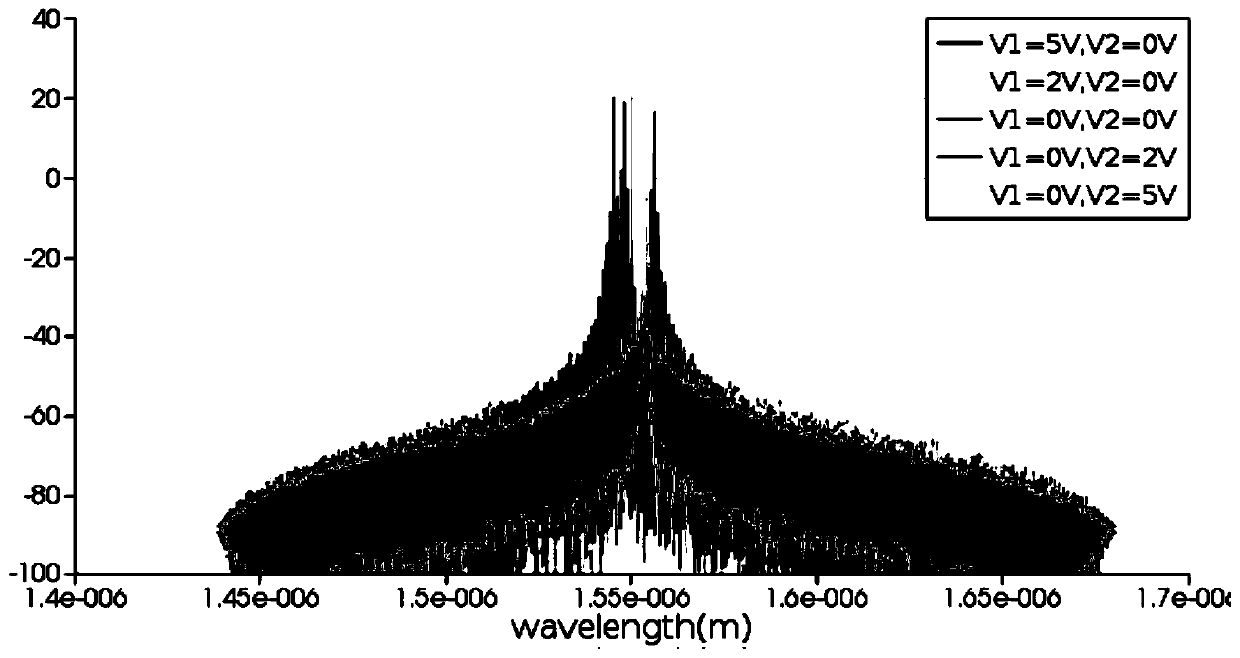

A lithium niobate and laser technology, applied in the field of high-speed wavelength tuning lasers, can solve the problems of unsatisfactory electro-optic effect, and achieve the effect of fast response speed and fast wavelength tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

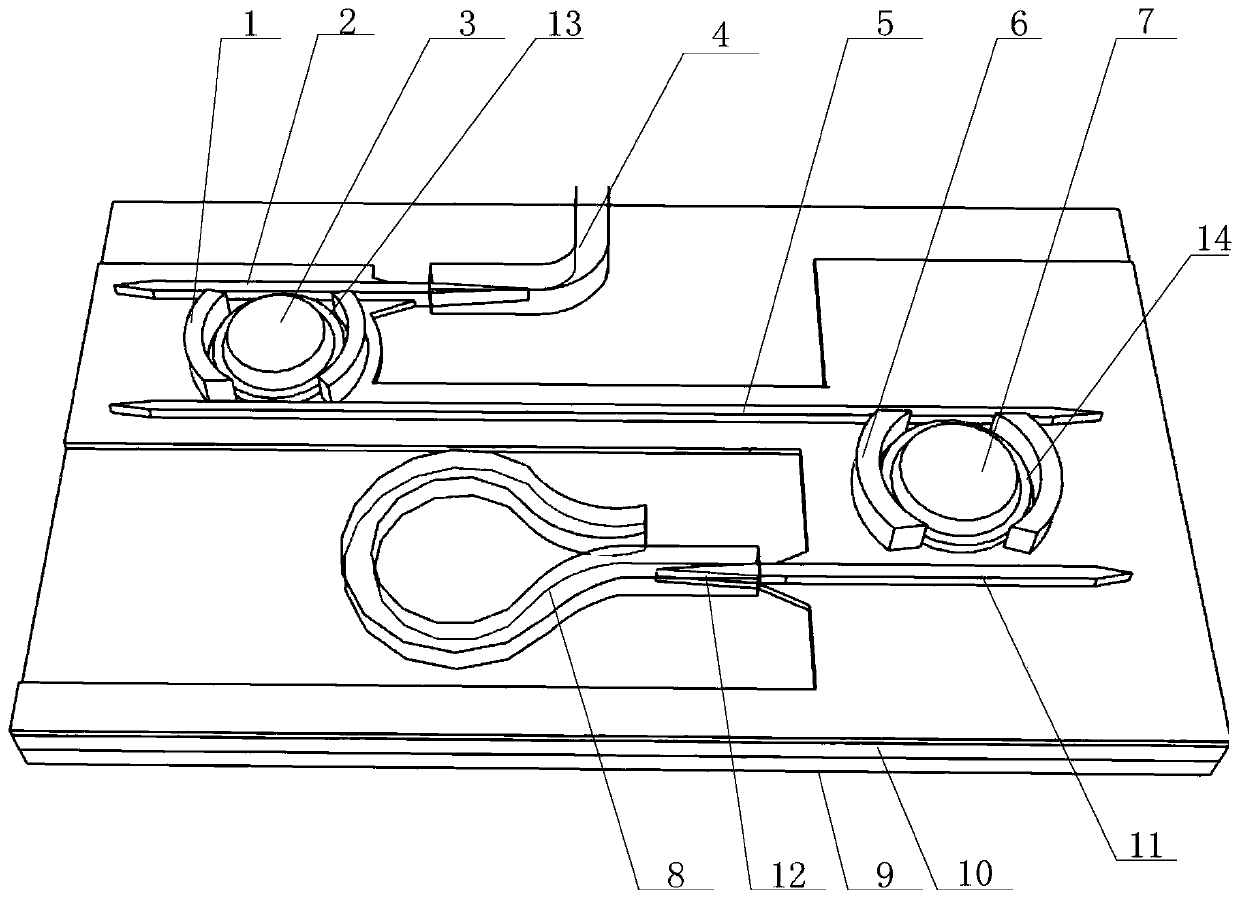

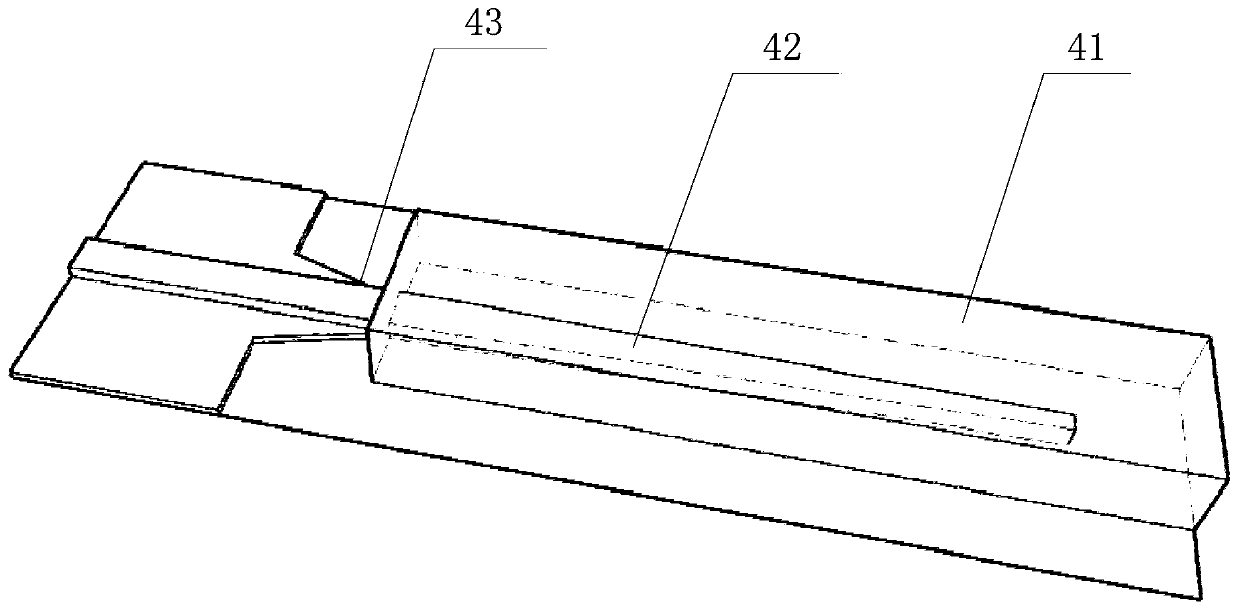

[0041] Such as figure 1 As shown, a high-speed wavelength-tunable laser made of lithium niobate material includes: a lithium niobate thin film chip (that is, an LNOI chip); a first mode spot converter 4 (SSC , spot sizeconverter); the composite resonant cavity connected to the first mode spot converter 4, the composite resonant cavity is made of lithium niobate material. Lithium niobate thin film chip comprises silicon substrate 9, the SiO that arranges silicon substrate 9 2 Buried oxide layer 10 and set on SiO 2 The lithium niobate thin film on the buried oxide layer 10 (that is, the lithium niobate film with a thickness of 10-999 nm).

[0042] The compound resonant cavity comprises: the input end waveguide 2 that is connected with the mode spot converter 4; The first ring resonator 13 that is coupled and connected with the input end waveguide 2; The cascade waveguide 5 that is coupled and connected with the first ring resonant cavity 13 (for light output); the second ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com