Silk fibroin fiber hollow nerve catheter, preparation method and application thereof

A silk fibroin, nerve conduit technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of poor mechanical properties and compression resilience, difficult cell growth preparation process, low porosity, etc., to achieve good mechanical properties. Performance and compression resilience, good biodegradability, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

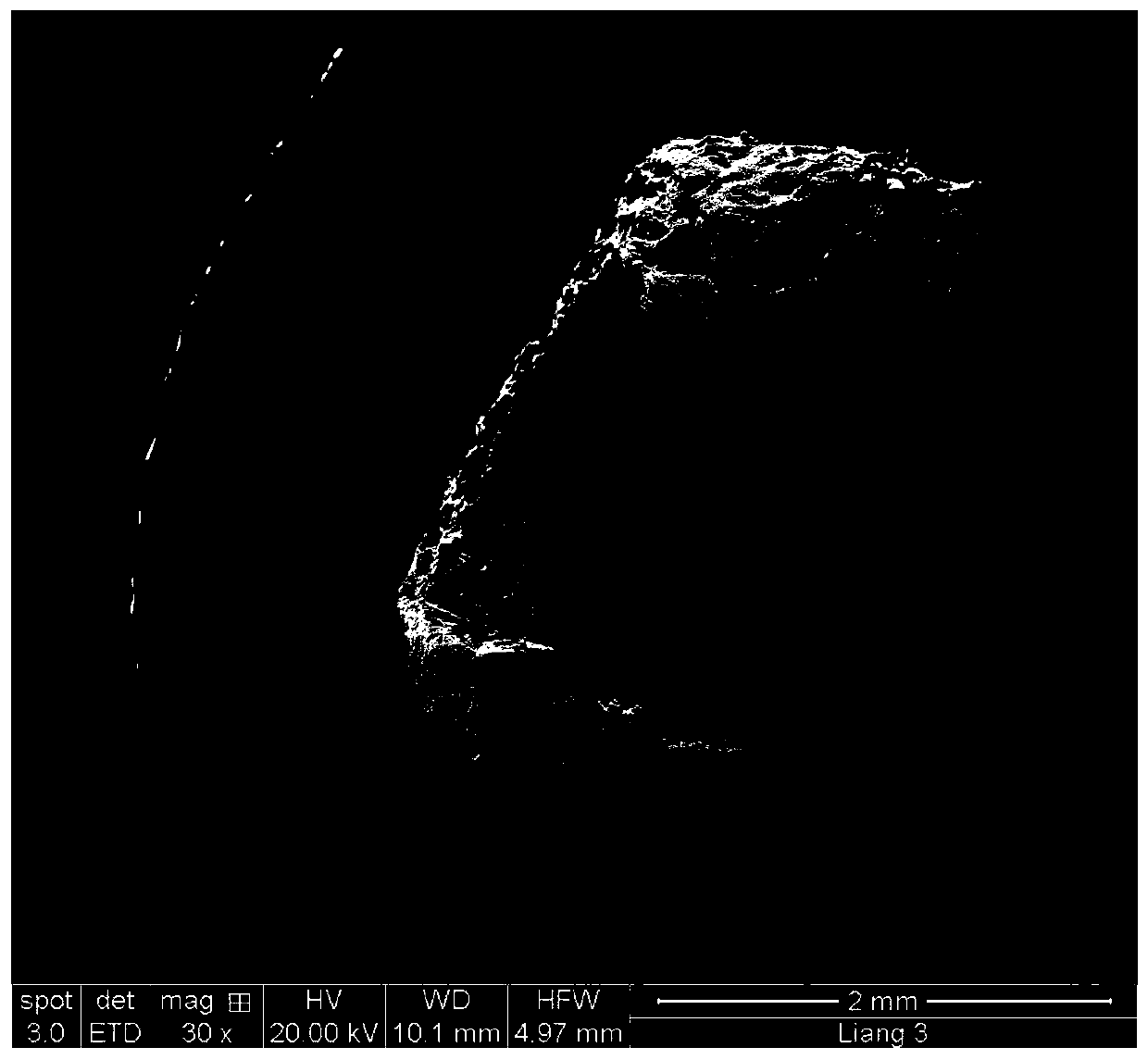

Image

Examples

Embodiment 1

[0039] Step 1: The silkworm cocoons are made of silkworm cocoons, and the silkworm cocoons are removed, and the silkworm cocoons are cut into pieces with scissors, and 1 part of the cut silkworm cocoons is weighed for later use; 0.5 parts of deionized water are taken with a measuring cylinder and added to a stainless steel iron pot, and heated in a microwave oven Until the deionized water boils; put 1 part of the cut cocoon into boiling deionized water and stir continuously with a glass rod, weigh 0.1 part of sodium carbonate and add it to a stainless steel pot, boil the cocoon for 10 minutes to remove the sericin; remove it with a glass rod Squeeze excess water out of silk fibroin fiber, wash silk fibroin fiber once with 1 part of deionized water to remove excess sodium carbonate in silk fiber; squeeze out excess water in silk fibroin fiber, put silk fibroin fiber by hand Tear it apart and spread it loosely on the aluminum foil, then place it in a fume hood for 1 day to allow ...

Embodiment 2

[0044]Step 1: The silkworm cocoon is made of silkworm cocoon, remove the silkworm cocoon, cut the silkworm cocoon into pieces with scissors, weigh 5 parts of the cut silkworm cocoon for later use; measure 1 part of deionized water with a measuring cylinder, add it to a stainless steel iron pot, and heat it on a microwave oven Until the deionized water boils; put 5 parts of silkworm cocoons into boiling deionized water and stir continuously with a glass rod, weigh 5 parts of sodium carbonate and add them to a stainless steel pot, boil the cocoons for 30 minutes to remove sericin; remove them with a glass rod Squeeze excess water out of silk fibroin fibers, wash silk fibroin fibers with 2 parts of deionized water for 3 times to remove excess sodium carbonate in silk fibers; squeeze out excess water in silk fibroin fibers, and wash silk fibroin fibers Tear it apart and spread it loosely on the aluminum foil, then place it in a fume hood for 2 days to allow the silk fibroin fiber t...

Embodiment 3

[0049] Step 1: The silkworm cocoon is made of silkworm cocoon, remove the silkworm cocoon, cut the silkworm cocoon into pieces with scissors, weigh 10 parts of the cut silkworm cocoon for later use; measure 2 parts of deionized water with a measuring cylinder, add it to a stainless steel iron pot, and heat it on a microwave oven Until the deionized water boils; put 10 parts of cut silkworm cocoons into boiling deionized water and stir continuously with a glass rod, weigh 10 parts of sodium carbonate and add it to a stainless steel pot, boil the silkworm cocoons for 60 minutes to remove sericin; fish out with a glass rod Squeeze excess water out of silk fibroin fiber, wash silk fibroin fiber with 3 parts of deionized water 3 times to remove excess sodium carbonate in silk fiber; squeeze out excess water in silk fibroin fiber, and wash silk fibroin fiber Tear it apart and spread it loosely on the aluminum foil, then place it in a fume hood for 3 days to allow the silk fibroin fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com