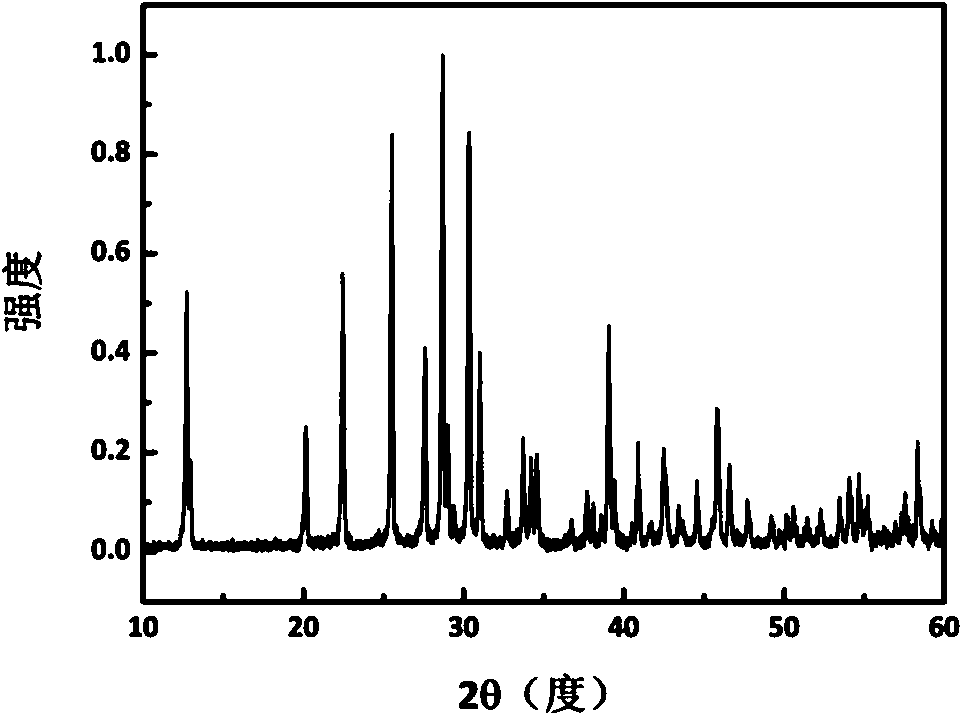

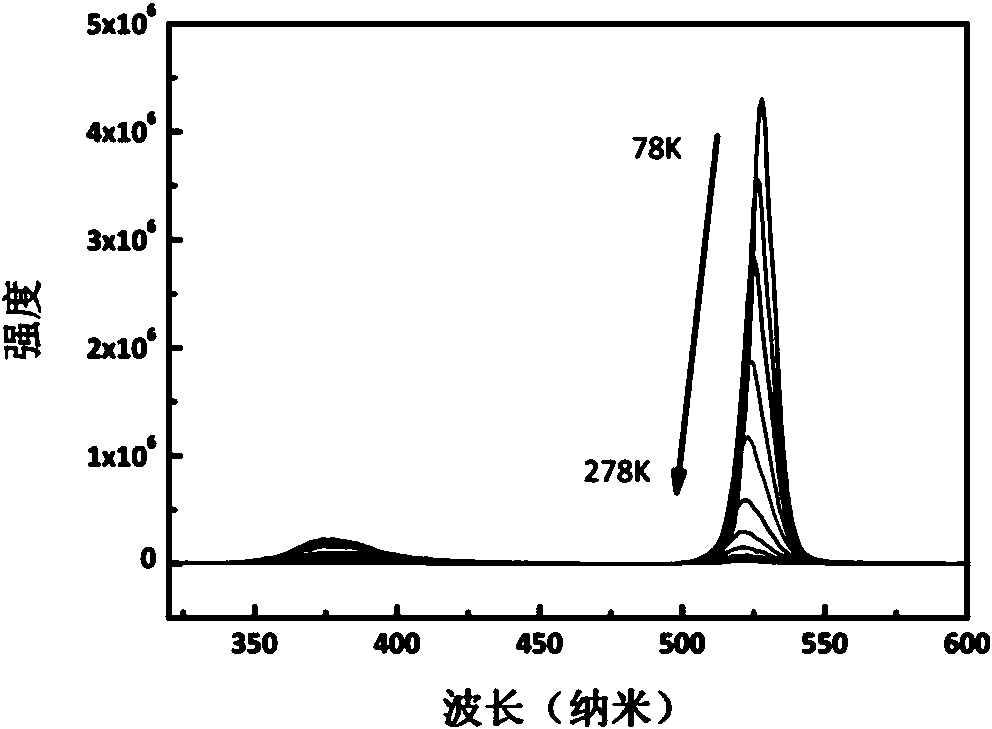

Cs4PbBr6/CsPbBr3 perovskite nanocrystalline scintillation powder and preparation method of Cs4PbBr6/CsPbBr3 perovskite nanocrystalline scintillation powder

A nanocrystal and perovskite technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of inability to collect radioactive signals, insufficient energy deposition, and limited material thickness, and achieve strong controllability, Simple preparation method and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) 25ml dimethyl sulfoxide is added to the container, and CsBr and PbBr 2 The powder is mixed into the solution according to the ratio of 1mol:1mol;

[0026] (2) Put the solution obtained in step (1) into an oil bath to heat and rotate, the heating temperature is set at 80° C., the rotation speed is 500 rpm, and the rotation time is 30 minutes;

[0027] (3) In the solution prepared in step (2), continue to add the powder added last time (that is, CsBr and PbBr mixed according to the ratio of 1mol:1mol 2 powder), continue to heat and rotate until the solution turns orange-yellow at high temperature;

[0028] (4) Leave the solution prepared in step (3) at room temperature of 20°C for 30 minutes to turn yellow-green;

[0029] (5) The solution prepared in step (4) is placed on the conical flask with a sand core funnel of 2 μm aperture and plugged tightly with a rubber stopper, and the conical flask is connected to a vacuum pump for suction filtration;

[0030] (6) The p...

Embodiment 2

[0033] (1) 25ml dimethyl sulfoxide is added to the container, and CsBr and PbBr 2 The powder is mixed into the solution according to the ratio of 1mol:1.5mol;

[0034] (2) Put the solution obtained in step (1) into an oil bath for heating and rotating, the heating temperature is set at 70° C., the rotating speed is 1000 rpm, and the rotating time is 30 minutes;

[0035] (3) In the solution prepared in step (2), continue to add the powder added last time (that is, CsBr and PbBr mixed according to the ratio of 1mol:1.5mol 2 powder), continue to heat and rotate until the solution turns orange-yellow at high temperature;

[0036](4) Leave the solution prepared in step (3) at room temperature of 22°C for 45 minutes to turn yellow-green;

[0037] (5) The solution prepared in step (4) is placed on the conical flask with a sand core funnel of 2.5 μm aperture and plugged tightly with a rubber stopper, and the conical flask is connected to a vacuum pump for suction filtration;

[003...

Embodiment 3

[0041] (1) 25ml dimethyl sulfoxide is added to the container, and CsBr and PbBr 2 The powder is mixed into the solution according to the ratio of 1mol:0.8mol;

[0042] (2) Put the solution obtained in step (1) into an oil bath for heating and rotating, the heating temperature is set at 75° C., the rotating speed is 1500 rpm, and the rotating time is 30 minutes;

[0043] (3) In the solution prepared in step (2), continue to add the powder added last time (that is, CsBr and PbBr mixed according to the ratio of 1mol:0.8mol 2 powder) repeat step (2), until the solution turns orange at high temperature;

[0044] (4) Put the solution prepared in step (3) at room temperature of 24° C. for 1 hour to turn yellow-green;

[0045] (5) The solution prepared in step (4) is placed on the conical flask with a sand core funnel of 2.5 μm aperture and plugged tightly with a rubber stopper, and the conical flask is connected to a vacuum pump for suction filtration;

[0046] (6) Wash the powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com