Prussian blue analogue nanosheet array material and water electrolysis application thereof

A technology of nanosheet array and Prussian blue, which is applied in the field of Prussian blue analog nanosheet array material, preparation and electrolysis of water, can solve the problems of low active site utilization, poor conductivity of PBA, and low electrocatalytic performance. Achieve the effects of fast mass transfer and electron transport capacity, high stability, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

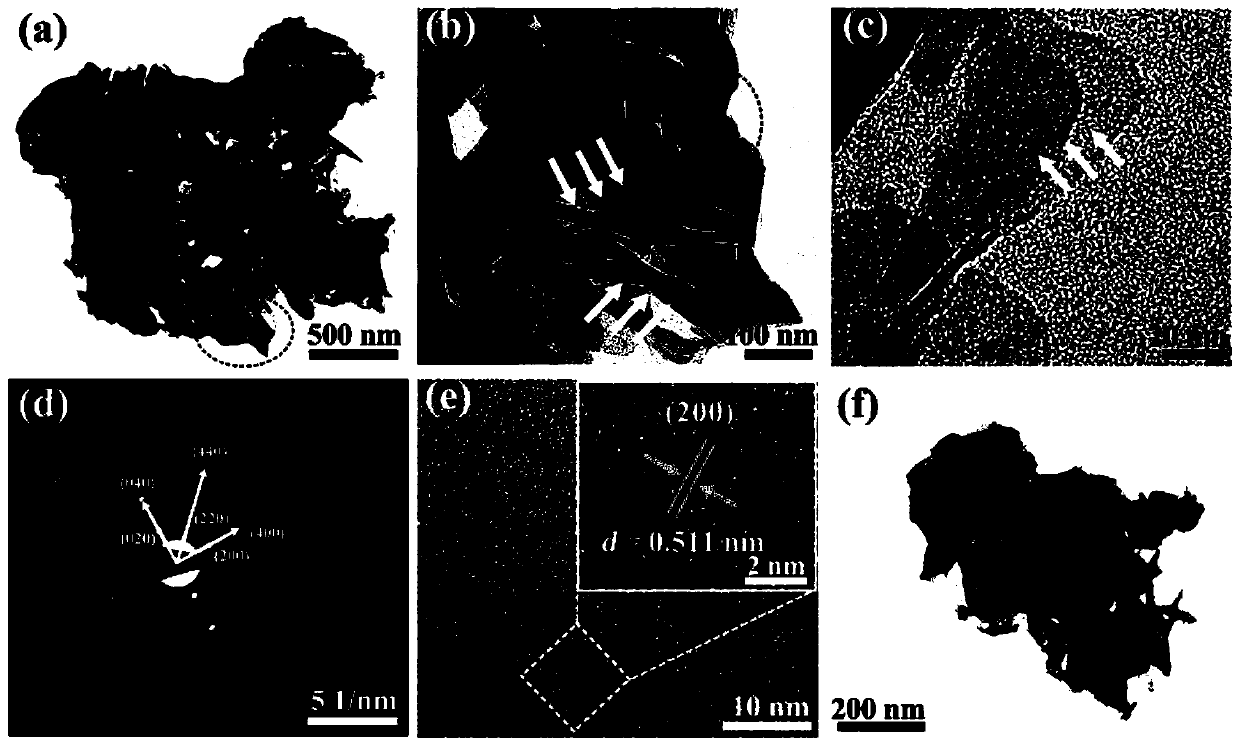

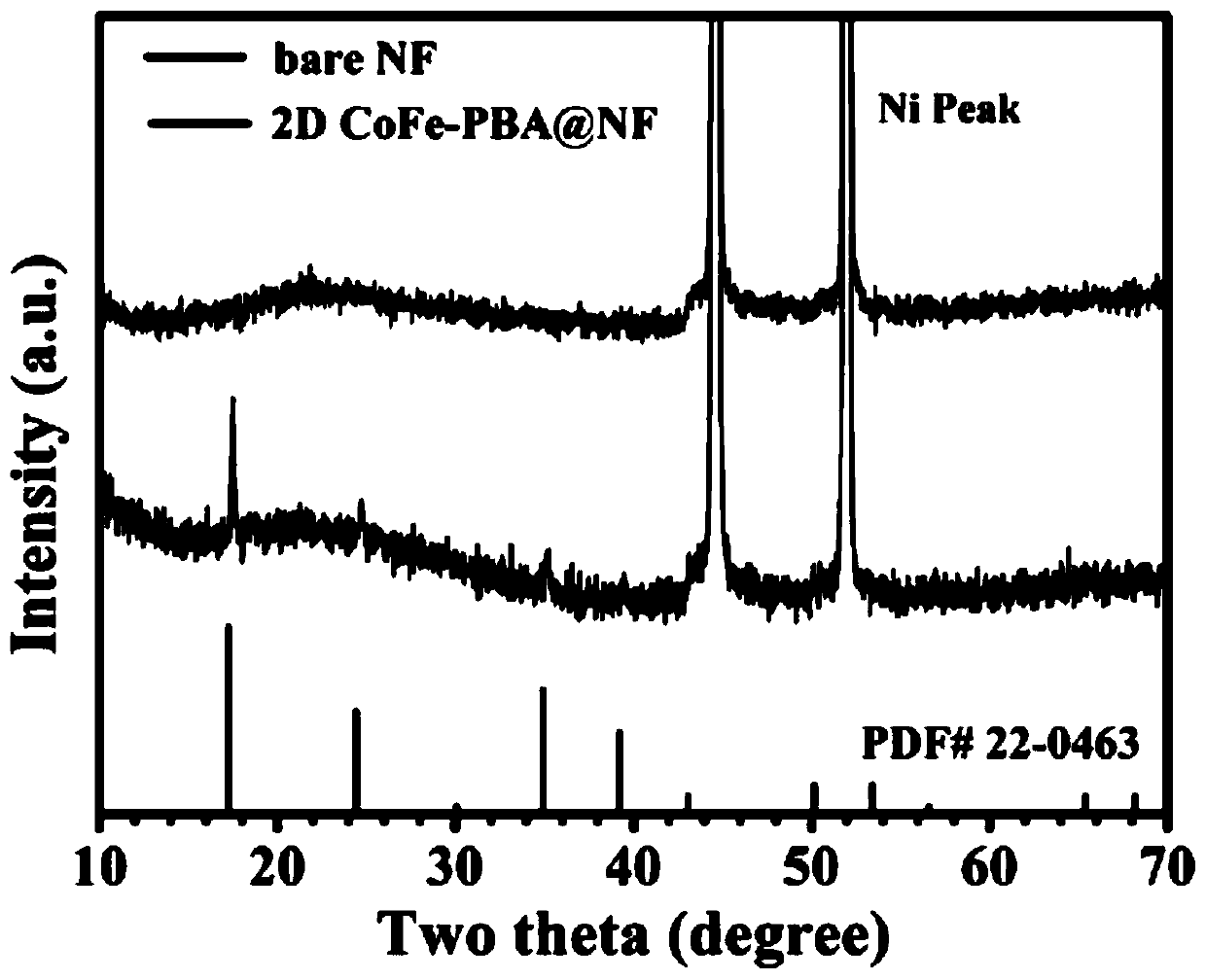

[0037] The preparation process of ultrathin Prussian blue analog nanosheet catalyst (2D CoFe-PBA@NF-24) is as follows:

[0038] 1) Cut blank nickel foam (1cm×2cm) and use acetone, ethanol, and deionized water to sonicate for 15 minutes respectively to remove surface pollutants, and put it in a 60°C oven for 6 hours before using it as a substrate.

[0039] 2) 100mL Co(NO 3 ) 2 ·6H 2 O (3mmol) aqueous solution was added to 100mL Na 2 Fe(CN) 5 NO·H 2 O (1 mmol) aqueous solution, the resulting solution was stirred at room temperature for 1 min until the solution became cloudy. Put the treated foamed nickel substrate into it, and let it stand in a dark place at room temperature for 24 hours. Finally, the nickel foam obtained by the reaction was rinsed with deionized water, and dried in an oven at 60°C for 12 hours to obtain the product 2D CoFe-PBA@NF-24.

[0040] When the 2D CoFe-PBA@NF-24 electrocatalyst prepared in this example is used to catalyze the hydrogen evolution re...

Embodiment 2

[0054] In this example, when Co(NO 3 ) 2 ·6H 2 O solution and Na 2 Fe(CN) 5 NO·H 2 After the O solution was mixed, the nickel foam substrate was put into the mixed solution, and left to react for 2 hours at room temperature in the dark, and the rest was the same as in Example 1 to prepare a 2D CoFe-PBA@NF-2 electrocatalyst.

Embodiment 3

[0056] In this example, when Co(NO 3 ) 2 ·6H 2 O solution and Na 2 Fe(CN) 5 NO·H 2 After the O solution was mixed, the nickel foam substrate was put into the mixed solution, and left to react for 12 hours at room temperature in the dark, and the rest was the same as in Example 1 to prepare a 2D CoFe-PBA@NF-12 electrocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com