Method for preventing tobacco sheets from being adhered during storage

A technology of tobacco flakes and protective agents, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment. It can solve the problems of flakes and flakes without a good diaphragm, molecular motion adhesion, and large contact area, so as to achieve long retention time, reduce adhesion, The effect of enhancing the stability of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of water-soluble rosin pentaerythritol ester:

[0027] Weigh 300 g of refined rosin, grind it into a 500 mL four-neck flask, heat and melt it, when the temperature rises to about 160-170°C, stir, slowly add a certain amount of maleic anhydride, and keep it at about 185-190°C , react for 2 hours, add a certain amount of pentaerythritol and 0.3g of a common esterification catalyst, heat up to 210-250°C, react for 2-5h, remove moisture and low boiling point substances, cool down to about 200°C, and discharge to obtain water-soluble rosin pentaerythritol esters.

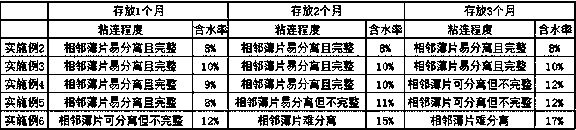

Embodiment 2

[0029] Preparation of anti-adhesive tobacco sheets:

[0030] Tobacco waste is manually cleaned, pretreated by washing stems, and dried;

[0031] Weigh 500g of the raw material after removal of impurities and put it into 2.5L extract solution, the extract solution is 2% urine solution aqueous solution, ultrasonic extraction at 40-60°C, the ultrasonic extraction frequency is 3KHz-5KHz, the extraction time is 4-6h, solid-liquid Extraction obtained after separation and treatment;

[0032] Centrifuge the extract with a butterfly centrifuge at 12000r / min, centrifuge for 3-5min, reduce the slag content, and take the supernatant;

[0033] Concentrate the purified extract to 40% using a double-effect rising film evaporator to obtain a concentrate;

[0034] Filter the concentrated solution through a 200-mesh rectangular sieve to obtain a filtered concentrated solution; according to the "Technical Specifications for Reconstituted Tobacco Leaf by Papermaking Method", add flavors and fra...

Embodiment 3

[0041] Preparation of anti-adhesive tobacco sheets:

[0042] Tobacco waste is manually cleaned, pretreated by washing stems, and dried;

[0043] Weigh 500g of the raw material after removal of impurities and put it into 2.5L extract solution, the extract solution is 2% urine solution aqueous solution, ultrasonic extraction at 40-60°C, the ultrasonic extraction frequency is 3KHz-5KHz, the extraction time is 4-6h, solid-liquid Extraction obtained after separation and treatment;

[0044] Centrifuge the extract with a butterfly centrifuge at 12000r / min, centrifuge for 3-5min, reduce the slag content, and take the supernatant;

[0045] Concentrate the purified extract to 40% using a double-effect rising film evaporator to obtain a concentrate;

[0046] Filter the concentrated solution through a 200-mesh rectangular sieve to obtain a filtered concentrated solution; according to the "Technical Specifications for Reconstituted Tobacco Leaf by Papermaking Method", add flavors and fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com