Anion adsorbent and preparation method thereof

An anion and adsorbent technology, which is applied in the field of anion adsorbents in industrial sewage, can solve the problems of low adsorption efficiency, and achieve the effect of simple preparation scheme, good adsorption performance, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

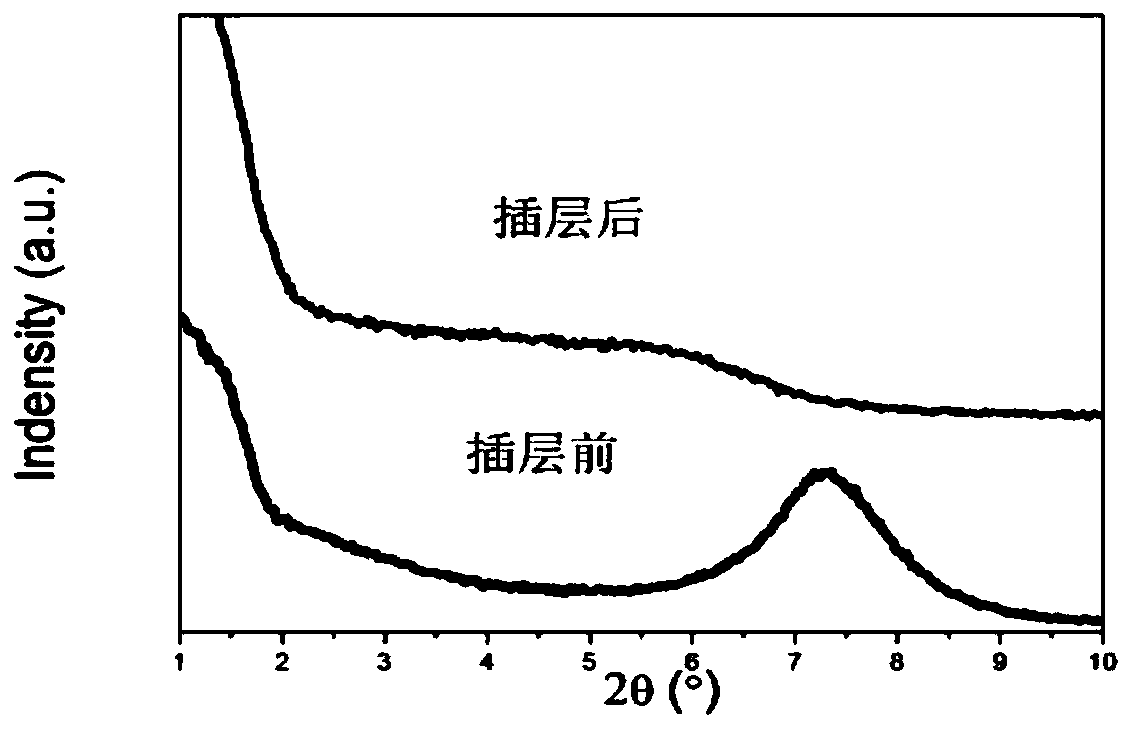

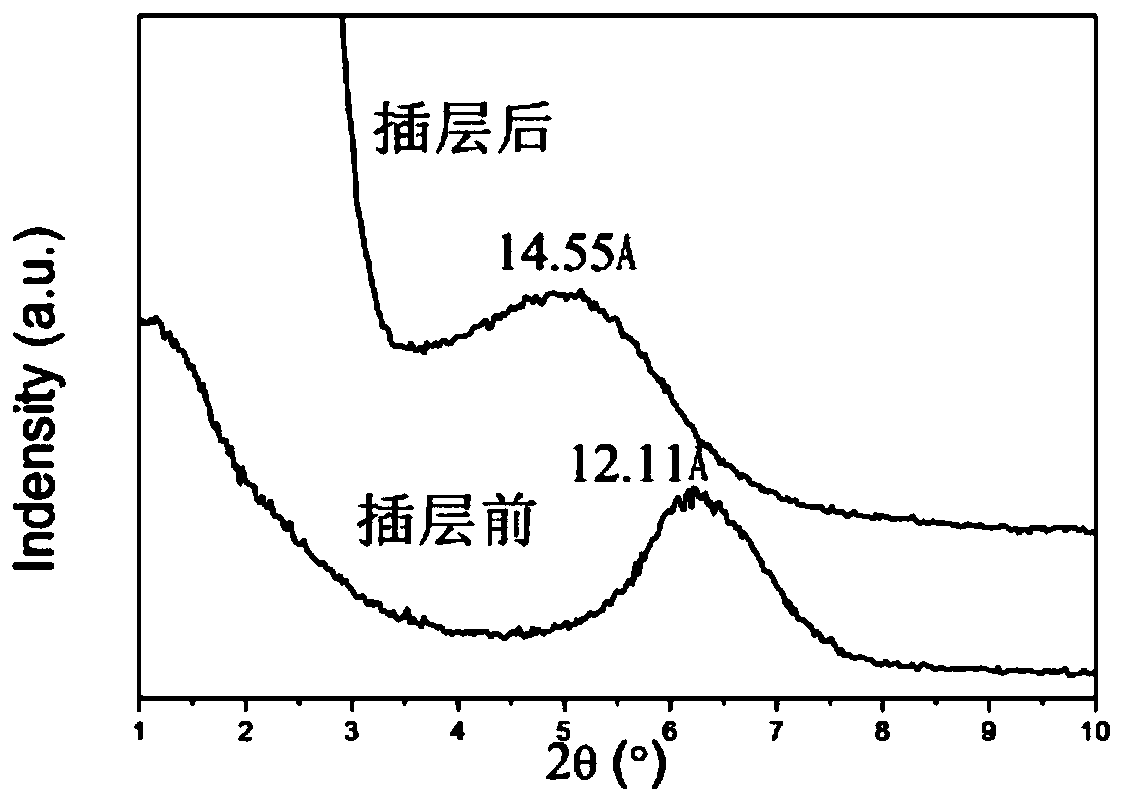

Method used

Image

Examples

Embodiment 1

[0025] Take 10 g of high-quality sodium-based montmorillonite and 90 g of water to make slurry, disperse at room temperature at high speed for 24 hours, and obtain smectite slurry. Add 1000g of polydiallyldimethylammonium chloride (PDDA) into the montmorillonite slurry, continue to disperse at a high speed under normal temperature conditions, centrifuge and wash three times with water after 24 hours, place it in a dryer at 60°C for drying, and grind Pass through a 200-mesh sieve to obtain an anion adsorbent.

[0026] The application effect is shown in the table below:

[0027] Add the anion adsorbent to the anion wastewater, stir and adsorb for 4 hours, and the adsorption is balanced. The anionic adsorbent is separated by centrifugation. To detect the concentration of anions in the supernatant. The results showed that after the treatment with anion adsorbent, the concentration of anion substances in sewage decreased significantly.

[0028]

Embodiment 2

[0030] Take 20g of high-quality sodium-based montmorillonite and 180g of water to make slurry, disperse at a high speed at room temperature for 24 hours, and obtain montmorillonite slurry. Add 2400g of polydiallyldimethylammonium chloride (PDDA) into the montmorillonite slurry, continue to disperse at a high speed under normal temperature conditions, centrifuge and wash three times with water after 24 hours, place it in a dryer at 60°C for drying, and grind Pass through a 200-mesh sieve to obtain an anion adsorbent.

[0031] The application effect is shown in the table below:

[0032] Add the anion adsorbent to the anion wastewater, stir and adsorb for 4 hours, and the adsorption is balanced. The anionic adsorbent is separated by centrifugation. To detect the concentration of anions in the supernatant. The results showed that after the treatment with anion adsorbent, the concentration of anion substances in sewage decreased significantly.

[0033]

Embodiment 3

[0035] Take 30g of high-quality sodium-based montmorillonite and 270g of water to make slurry, and disperse at high speed for 24 hours at room temperature to obtain montmorillonite slurry. Add 4500g of polydiallyldimethylammonium chloride (PDDA) into the montmorillonite slurry, continue to disperse at a high speed under normal temperature conditions, centrifuge and wash three times with water after 24 hours, place it in a dryer at 60°C for drying, and grind Pass through a 200-mesh sieve to obtain an anion adsorbent.

[0036] The application effect is shown in the table below:

[0037] Add the anion adsorbent to the anion wastewater, stir and adsorb for 4 hours, and the adsorption is balanced. The anionic adsorbent is separated by centrifugation. To detect the concentration of anions in the supernatant. The results showed that after the treatment with anion adsorbent, the concentration of anion substances in sewage decreased significantly.

[0038]

[0039] The above exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com