Phosphorescent compound and preparation method thereof and application of compound to electroluminescent device

A compound and phosphorescence technology, which is applied in the direction of electric solid-state devices, indium organic compounds, platinum group organic compounds, etc., can solve the problems of increased phosphorescence life, short device life, and low luminous efficiency of devices, achieving long phosphorescence life and high luminescence The effect of high efficiency and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

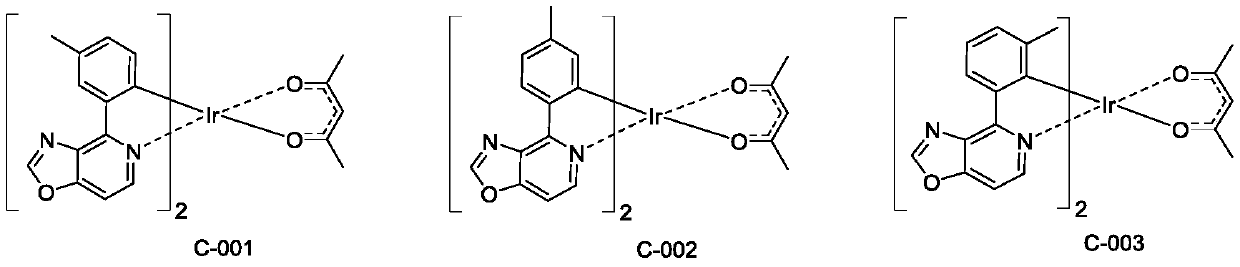

[0046] Embodiment 1 prepares compound C-001

[0047]

[0048] Step 1. Weigh A-001 (48mmol, 10.1g), IrCl 3 ·3H 2 O (19.2mmol, 6.8g), ethylene glycol ether (60mL), water (20mL) joins reaction system respectively, under N 2 Heated to reflux for 24h under protection, then cooled to room temperature, precipitates were precipitated, filtered under reduced pressure, rinsed with absolute ethanol and petroleum ether, and dried to obtain intermediate B-001 (7.5g, yield: 60.5 %).

[0049] Step 2, weigh intermediate B-001 (3.8mmol, 4.9g), K 2 CO 3 (26mmol, 3.6g), ethylene glycol ether (30mL) joins reaction system respectively, under N 2 Add 2,4-pentanedione (11.4mmol, 1.1g) under protection, raise the temperature to 120°C, heat to reflux for 24h, cool to room temperature, filter under reduced pressure, rinse the filter cake with ethanol at -0.1Mpa, Dry at 50° C., pass through a silica gel column, and spin dry the obtained filtrate to obtain the target product C-001 (2.7 g, yield ...

Embodiment 2

[0055] Embodiment 2 prepares compound C-004

[0056]

[0057] Step 1. Weigh A-004 (45mmol, 10.1g), IrCl 3 ·3H 2 O (18mmol, 6.3g), ethylene glycol ether (60mL), water (20mL) joins reaction system respectively, under N 2 Heated to reflux for 24h under protection, then cooled to room temperature, precipitates were precipitated, filtered under reduced pressure, rinsed with absolute ethanol and petroleum ether, and dried to obtain intermediate B-004 (6.5g, yield 53.4 %).

[0058] Step 2, weigh intermediate B-004 (3.7mmol, 5.0g), K 2 CO 3 (26mmol, 3.6g), ethylene glycol ether (30mL) joins reaction system respectively, under N 2 Add 2,4-pentanedione (11.1mmol, 1.1g) under protection, raise the temperature to 120°C, heat to reflux for 24h, cool to room temperature, filter under reduced pressure, rinse the filter cake with ethanol, at -0.1Mpa, Dry at 50°C, pass through a silica gel column, and spin dry the obtained filtrate to obtain the target product C-004 (2.1 g, yield 38.8...

Embodiment 3

[0064] Embodiment 3 prepares compound C-007

[0065]

[0066] Step 1. Weigh A-007 (42mmol, 10.0g), IrCl 3 ·3H 2 O (16.8mmol, 5.9g), ethylene glycol ether (60mL), water (20mL) joins reaction system respectively, under N 2 Heated to reflux for 24h under protection, then cooled to room temperature, precipitates were precipitated, filtered under reduced pressure, rinsed with absolute ethanol and petroleum ether, and dried to obtain intermediate B-007 (5.7g, yield 48.5 %).

[0067] Step 2, weigh intermediate B-007 (3.5mmol, 4.9g), K 2 CO 3 (26mmol, 3.6g), ethylene glycol ether (30mL) joins reaction system respectively, under N 2 Add 2,4-pentanedione (10.5mmol, 1.0g) under protection, increase the temperature to 120°C, heat to reflux for 24h, cool to room temperature, filter under reduced pressure, and rinse the filter cake with ethanol at -0.1Mpa, Dry at 50°C, pass through a silica gel column, and spin dry the obtained filtrate to obtain the target product C-007 (2.2 g, yi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com