A shape memory polymer with high temperature resistance and high performance, its preparation method and application

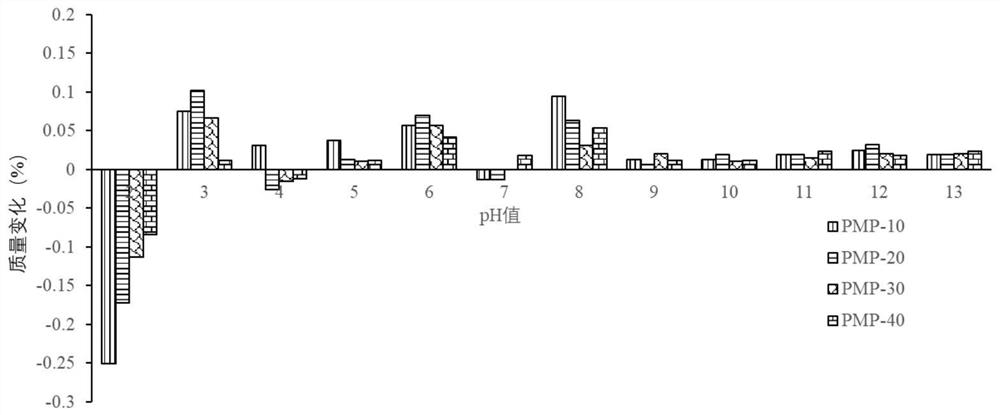

A memory polymer, high-performance technology, applied in the field of smart materials, can solve the problems of low cross-linking density, low material ambient temperature, shape memory properties, mechanical properties and chemical stability effects, etc. Link density, improve the effect of lower application temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

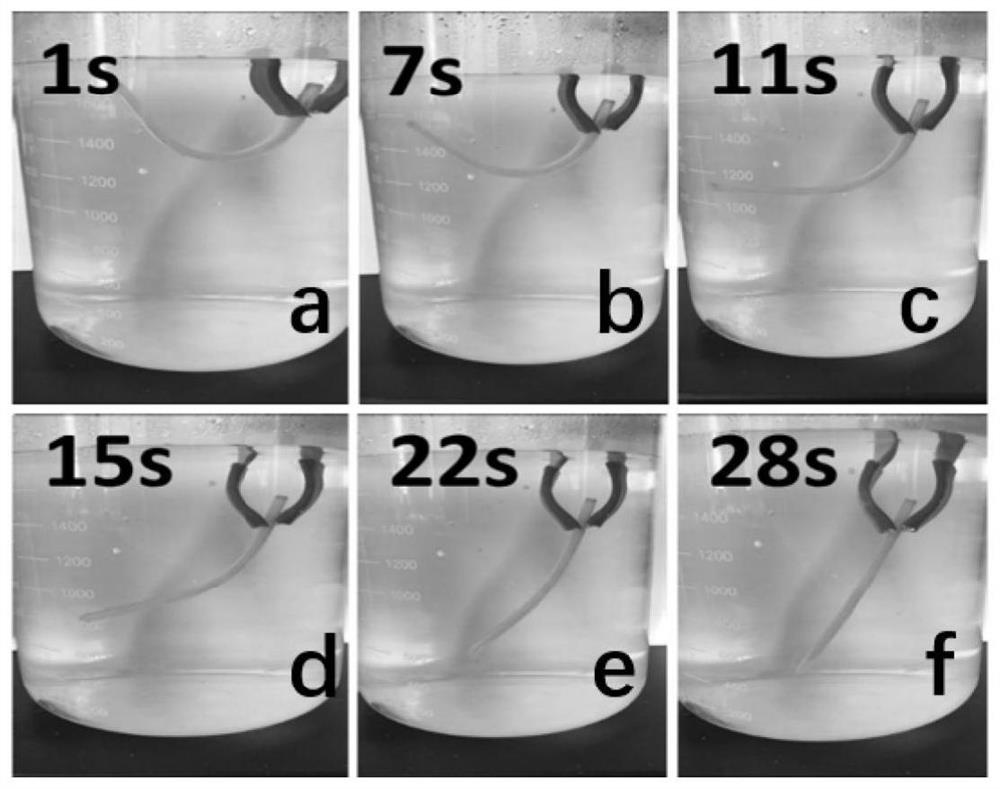

Examples

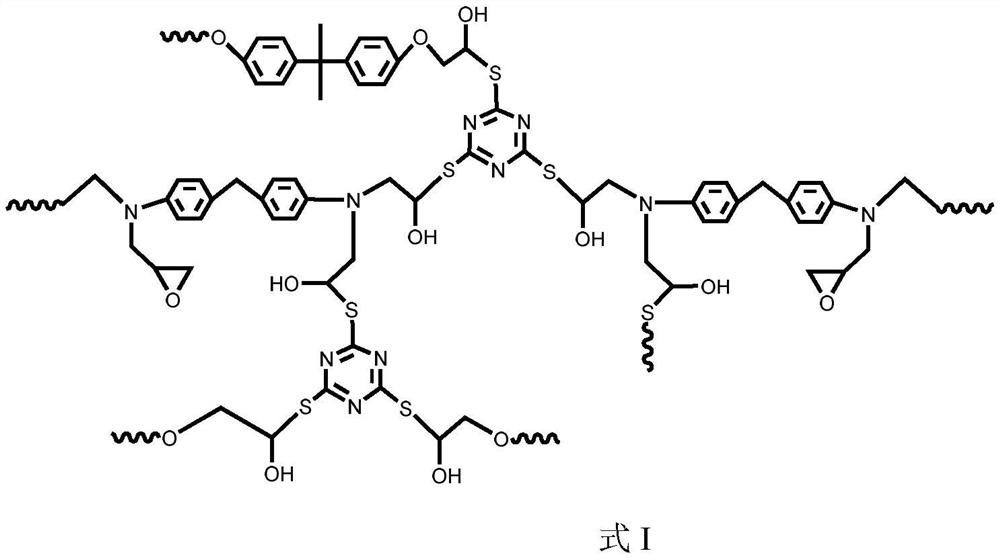

Embodiment 1

[0036] The mass of epoxy resin E51, N,N,N',N'-tetraepoxypropyl-4,4'-diaminodiphenylmethane was 9g and 1g respectively, and the mass of thiocyanuric acid was 4.8g, Mix with 0.075 g of the catalyst 2-methylimidazole, place it under vacuum condition of -0.08 MPa and stir for 30 min. Pour the uniformly stirred mixture into a polytetrafluoroethylene mold, and place it under vacuum conditions, react at 80°C for 3h, at 120°C for 2h, and at 150°C for 1h, and after 24 hours of subsequent natural cooling treatment, high temperature resistant Epoxy resin shape memory polymer material.

Embodiment 2

[0038] Epoxy resin E51, N,N,N',N'-tetraepoxypropyl-4,4'-diaminodiphenylmethane were 8g, 2g, thiocyanate 5.1g, and catalyst 2- Mix 0.075 g of methylimidazole and stir for 30 min under vacuum condition of -0.08 MPa. Pour the uniformly stirred mixture into a polytetrafluoroethylene mold, and place it under vacuum conditions, react at 80°C for 3h, at 120°C for 2h, and at 150°C for 1h, and after 24 hours of subsequent natural cooling treatment, high temperature resistant Epoxy resin shape memory polymer material.

Embodiment 3

[0040] 7g of epoxy resin E51, 3g of N,N,N',N'-tetraepoxypropyl-4,4'-diaminodiphenylmethane, 5.3g of trithiocyanuric acid and catalyst 2-methylimidazole 0.075g was mixed, placed under vacuum condition of -0.08MPa and stirred for 30min. Pour the uniformly stirred mixture into a polytetrafluoroethylene mold, and place it under vacuum conditions, react at 80°C for 3h, at 120°C for 2h, and at 150°C for 1h, and after 24 hours of subsequent natural cooling treatment, high temperature resistant Epoxy resin shape memory polymer material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com