High-fouling-resistance low-temperature-resistant polyester monofilament and production method thereof

A production method and low temperature-resistant technology, applied in the direction of single-component polyester rayon, rayon manufacturing, fiber chemical characteristics, etc., can solve problems affecting work performance, service life and scope of use, and high corrosion resistance requirements. , to achieve the effect of improving anti-fouling ability, improving corrosion resistance and low temperature performance, and using a wide range of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

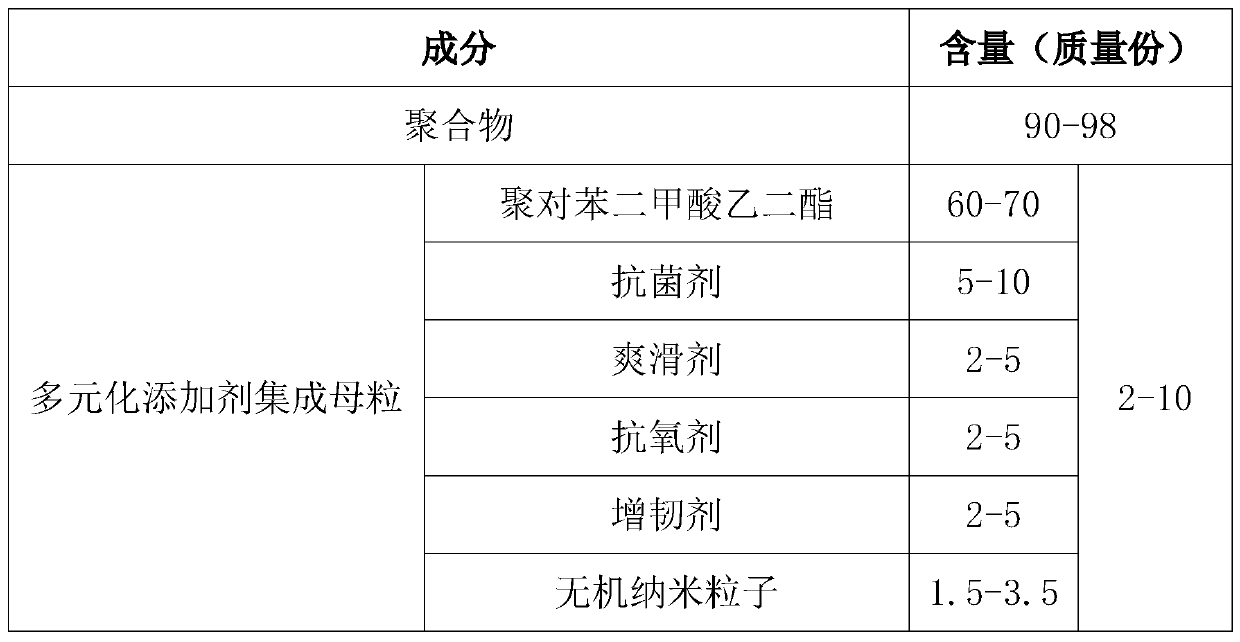

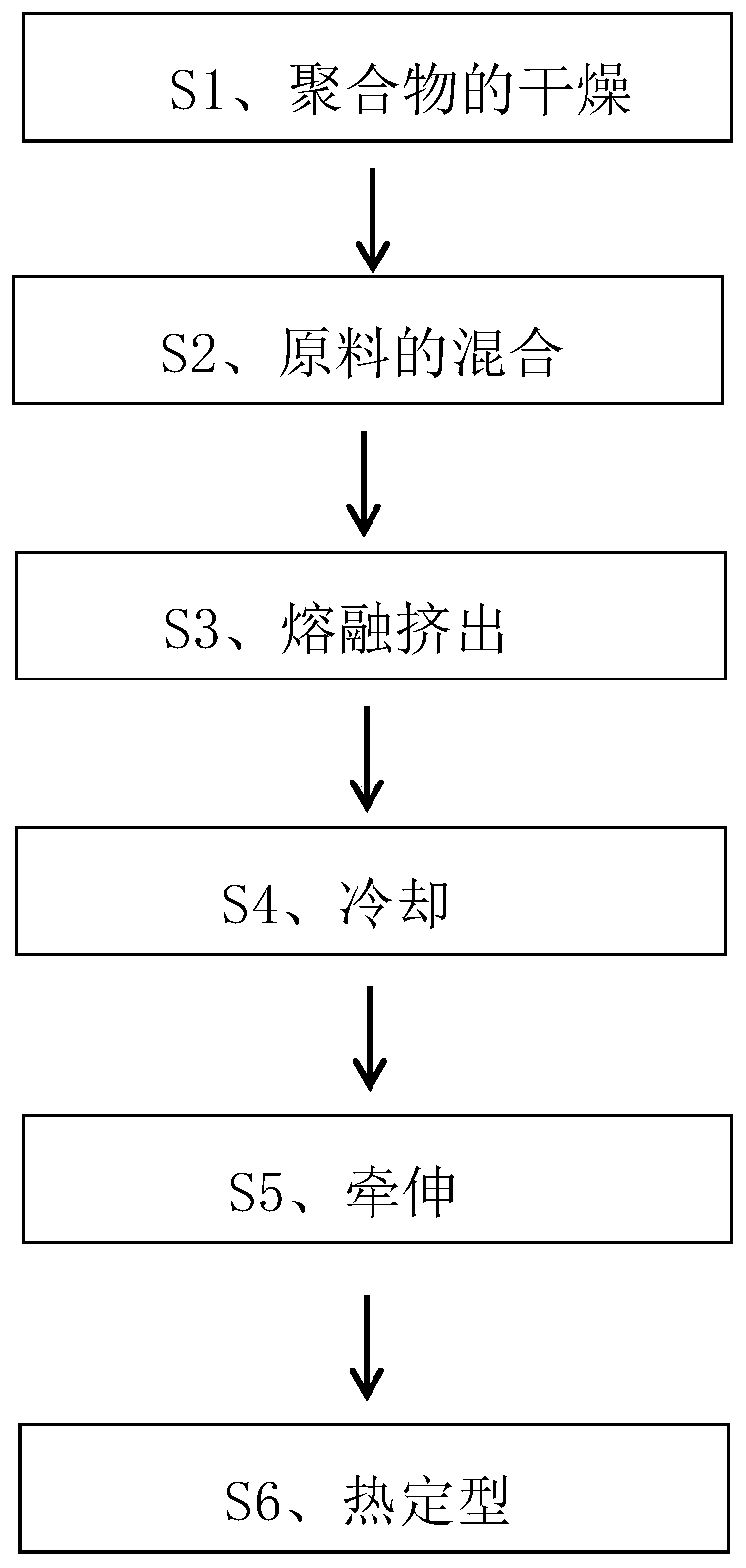

[0061] Such as figure 1 Said, a polyester monofilament with high anti-fouling and low temperature resistance, the polyester monofilament includes a polymer and a multi-component additive integrated masterbatch; the weight part of the polymer is 90-98 parts, and the multi-component additive The integrated masterbatch is 2-10 parts by weight. The polymer is a glass fiber reinforced polymer, especially a 30% glass fiber reinforced polymer.

[0062] The polymer is high viscosity high viscosity polyethylene terephthalate. The composition and content of the multi-component additive integrated masterbatch are 60-70 parts of high-viscosity polyethylene terephthalate, 5-10 parts of antibacterial agent, 2-5 parts of slip agent, 2-5 parts of antioxidant parts, 2-5 parts of toughening agent. The above ingredients are mixed in proportion, extruded into strips by a screw extruder, cooled, and pelletized to obtain a diversified additive integrated masterbatch.

[0063] The antibacterial ...

Embodiment 2

[0083] A polyester monofilament with high anti-fouling and low temperature resistance, the polyester monofilament includes a polymer and a diversified additive integrated masterbatch; the weight part of the polymer is 90-98 parts, and the diversified additive integrated masterbatch The parts by weight are 2-10 parts. The polymer is a glass fiber reinforced polymer, especially a 30% glass fiber reinforced polymer.

[0084] The polymer is high viscosity high viscosity polyethylene terephthalate. The composition and content of the multi-component additive integrated masterbatch are 60-70 parts of high-viscosity polyethylene terephthalate, 5-10 parts of antibacterial agent, 2-5 parts of slip agent, 2-5 parts of antioxidant parts, 2-5 parts of toughening agent. The above ingredients are mixed in proportion, extruded into strips by a screw extruder, cooled, and pelletized to obtain a diversified additive integrated masterbatch.

[0085] The multiple additive integrated masterbatc...

Embodiment 3

[0106] A polyester monofilament with high anti-fouling and low temperature resistance, the polyester monofilament includes a polymer and a diversified additive integrated masterbatch; the weight part of the polymer is 90-98 parts, and the diversified additive integrated masterbatch The parts by weight are 2-10 parts. The polymer is a glass fiber reinforced polymer, especially a 30% glass fiber reinforced polymer.

[0107] The polymer is high viscosity high viscosity polyethylene terephthalate. The composition and content of the multi-component additive integrated masterbatch are 60-70 parts of high-viscosity polyethylene terephthalate, 5-10 parts of antibacterial agent, 2-5 parts of slip agent, 2-5 parts of antioxidant parts, 2-5 parts of toughening agent. The above ingredients are mixed in proportion, extruded into strips by a screw extruder, cooled, and pelletized to obtain a diversified additive integrated masterbatch.

[0108] The multiple additive integrated masterbatc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Monofilament strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com