Natural dye dyeing method

A technology of natural dyes and dyeing methods, which is applied in dyeing methods, textiles and papermaking, etc. It can solve the problems of unsatisfactory dyeing effect, unconsidered metal ion hydrolysis and coordination, etc., and achieve the effect of improving fastness and facilitating penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

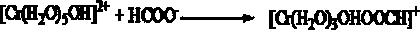

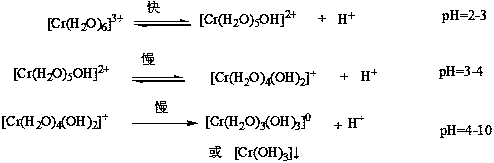

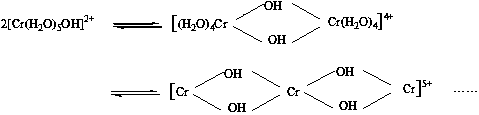

Method used

Image

Examples

Embodiment 1

[0025] Step 1): Dye the silk fabric with curcumin, the amount of natural dye is 0.5% (o.m.f), the liquor ratio is 1:20, the dyeing temperature is 50°C, and the dyeing time is 30 minutes. After dyeing, the fabric is washed 3 times with water and aired naturally dry, spare;

[0026] Step 2): Dissolve the mordant ferrous sulfate in deionized water, adjust the pH value to 3 with formic acid, add anhydrous sodium sulfate, and wait until it is completely dissolved for later use.

[0027] Step 3): Immerse the fabric dyed in step (1) into the above-mentioned mordant bath. The dosage of each component in the mordant bath is: ferrous sulfate dosage 2% (o.m.f), anhydrous sodium sulfate 5g / L; liquor ratio 1:5 , treat at 20°C for 90 minutes, add deionized water to dilute to a bath ratio of 1:30; then raise the temperature to 50°C, and after 60 minutes of treatment, adjust the pH value of the solution to 6 with baking soda, keep warm for 10 minutes, take out the fabric, and wash the fabric ...

Embodiment 2

[0032] Step 1): Dye the wool fabric with chestnut shell pigment, the amount of natural dye is 5% (o.m.f), the bath ratio is 1:40, the dyeing temperature is 80°C, and the dyeing time is 30 minutes. dry, ready for use;

[0033] Step 2): Dissolve the mordant ferric chloride in deionized water, adjust the pH value to 4 with formic acid, add anhydrous sodium sulfate, and wait until it is completely dissolved for later use.

[0034] Step 3): Immerse the fabric dyed in step (1) into the above-mentioned mordant bath. The dosage of each component in the mordant bath is: ferric chloride dosage 4% (o.m.f), anhydrous sodium sulfate 10g / L; liquor ratio 1:8 , treated at 25°C for 45 minutes, added deionized water to dilute to a bath ratio of 1:40; then raised the temperature to 60°C, and after 30 minutes of treatment, adjusted the pH value of the solution to 7 with baking soda. After rinsing with the solution, wash it with water 5 times and let it dry naturally.

Embodiment 3

[0039] Step 1): Dye silk / wool blended fabrics with gardenia yellow pigment, the amount of natural dyes is 1% (o.m.f), the liquor ratio is 1:30, the dyeing temperature is 60°C, and the dyeing time is 40 minutes. After dyeing, the fabric is washed with water 4 times, dry naturally, and set aside;

[0040] Step 2): Dissolve the mordant aluminum sulfate in deionized water, adjust the pH value to 3.5 with formic acid, add anhydrous sodium sulfate, and wait until it is completely dissolved for later use.

[0041] Step 3): Immerse the fabric dyed in step (1) into the above-mentioned mordant bath. The dosage of each component in the mordant bath is: aluminum sulfate dosage 3% (o.m.f), anhydrous sodium sulfate 6g / L; liquor ratio 1:6, Treat at 22°C for 60 minutes, add deionized water to dilute to a bath ratio of 1:35; then raise the temperature to 55°C, after 45 minutes of treatment, adjust the pH of the solution to 6.5 with baking soda, keep warm for 12 minutes, take out the fabric, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com