Compound purely natural hair dye and production method thereof

A production method and technology for hair dyes, which are applied in pharmaceutical formulations, hair care, cosmetic preparations, etc., can solve the problems of unresolved dyeing fastness, single dyeing type, etc., so as to improve the color fastness, expand the scope of application, and avoid excitement. or inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

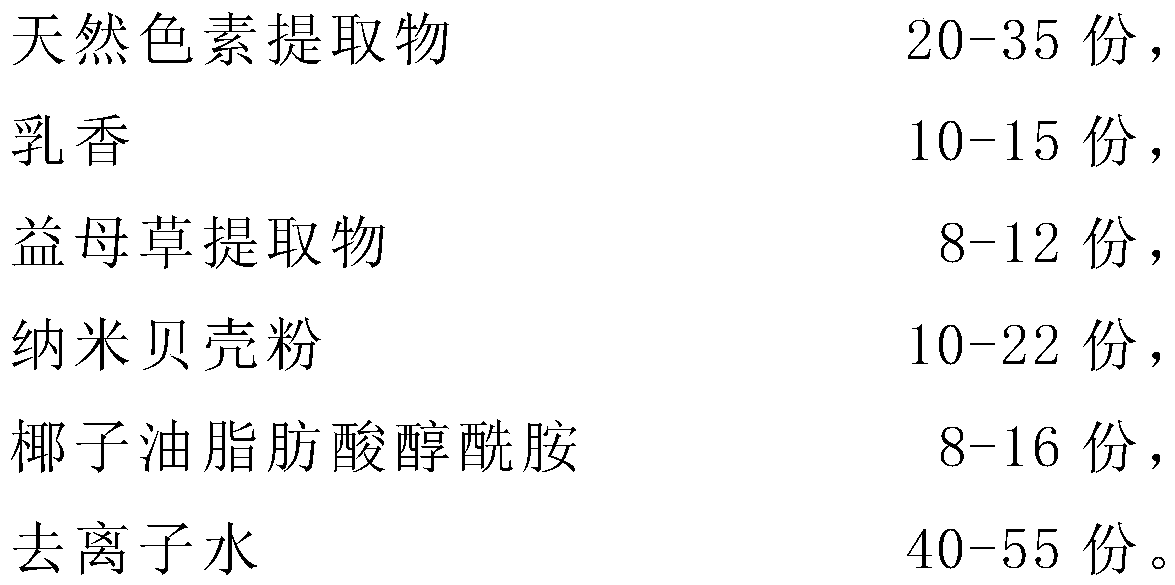

Embodiment 1

[0028] A, prepare each raw material component.

[0029] Preparation of natural pigment extract: In this example, Polygonum multiflorum rehmanniae complex extract was selected as the natural pigment.

[0030] (1) Take 15kg Polygonum multiflorum and 35kg Rehmannia glutinosa and dry until the moisture content is ≤10%;

[0031] (2) After the dried Radix Polygoni Multiflori and Rehmannia glutinosa are pulverized, pass through an 80-mesh sieve;

[0032] (3) re-grind the unsifted components and sieve, repeat step (2) 3 to 4 times;

[0033] (4) Utilize ethanol as a solvent to carry out ultrasonic extraction, the extraction time can be selected from 25-45min, and this embodiment selects 25min; the extraction temperature can be selected from 55-75°C, this embodiment selects 55°C; the extraction power can be selected from 60-75w, This embodiment selects 60w; repeat 2-3 times to obtain the filtrate.

[0034] (5) Concentrate the filtered filtrate under reduced pressure: use a double-eff...

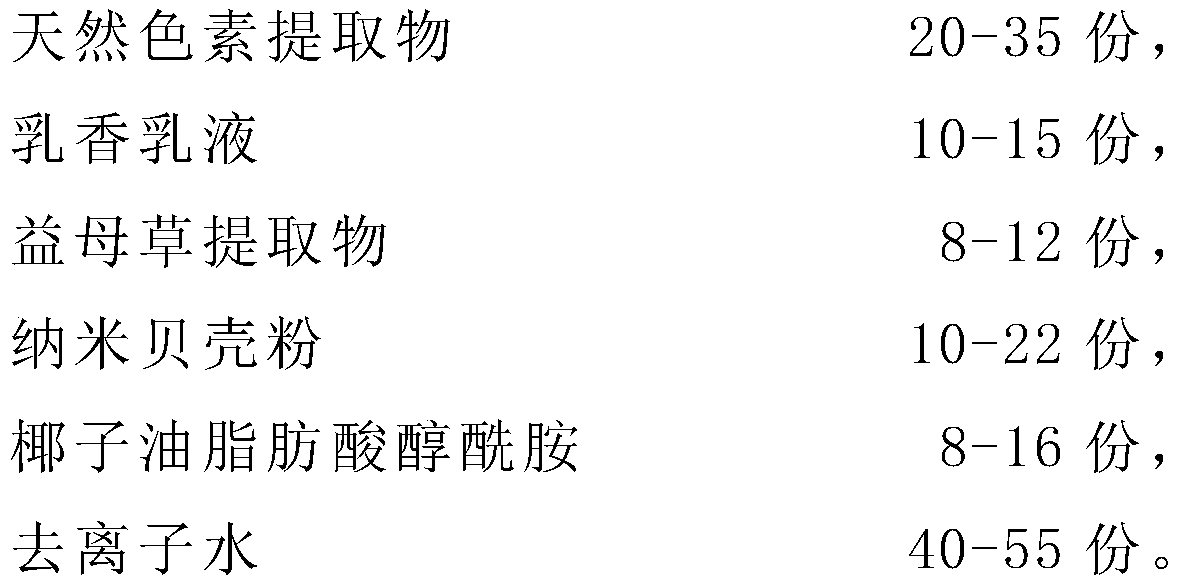

Embodiment 2

[0046] A, prepare each raw material component.

[0047] Preparation of natural pigment extract: In this example, Polygonum multiflorum rehmanniae complex extract was selected as the natural pigment.

[0048] (1) Take 15kg Polygonum multiflorum and 35kg Rehmannia glutinosa and dry until the moisture content is ≤10%;

[0049] (2) After the dried Radix Polygoni Multiflori and Rehmannia glutinosa are pulverized, pass through an 80-mesh sieve;

[0050] (3) re-grind the unsifted components and sieve, repeat step (2) 3 to 4 times;

[0051] (4) Using ethanol as a solvent, carry out ultrasonic extraction, the extraction time is 45min, the extraction temperature is 75°C, the extraction power is 75w, repeat 2-3 times to obtain the filtrate;

[0052] (5) Concentrate the filtered filtrate under reduced pressure: use a double-effect concentrator to concentrate to 0.8-1.2, use a spherical decompressor to concentrate the concentrated solution under reduced pressure, and finally obtain a rel...

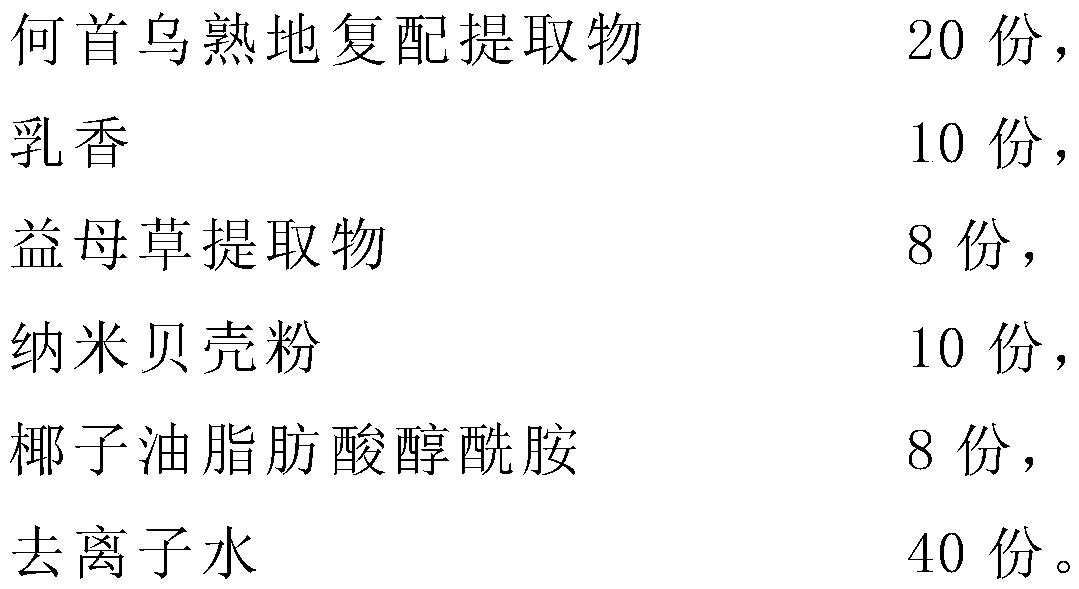

Embodiment 3

[0064] A, prepare each raw material component.

[0065] Preparation of natural pigment extract: In this example, Polygonum multiflorum rehmanniae complex extract was selected as the natural pigment.

[0066] (1) Take 15kg Polygonum multiflorum and 35kg Rehmannia glutinosa and dry until the moisture content is ≤10%;

[0067] (2) After the dried Radix Polygoni Multiflori and Rehmannia glutinosa are pulverized, pass through an 80-mesh sieve;

[0068] (3) re-grind the unsifted components and sieve, repeat step (2) 3 to 4 times;

[0069] (4) Using ethanol as a solvent, carry out ultrasonic extraction, the extraction time is 30min, the extraction temperature is 60°C, the extraction power is 65w, repeat 2-3 times to obtain the filtrate;

[0070] (5) Concentrate the filtered filtrate under reduced pressure: use a double-effect concentrator to concentrate to 0.8-1.2, use a spherical decompressor to concentrate the concentrated solution under reduced pressure, and finally obtain a rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com