A kind of hydrophilic polymer film and its preparation method and application

A technology of hydrophilic polymers and polymer membranes, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problems of poor hydrophilicity and low porosity of pure PBT membranes, and achieve enhanced selective permeability and environmental protection. Friendly, simple and economical preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

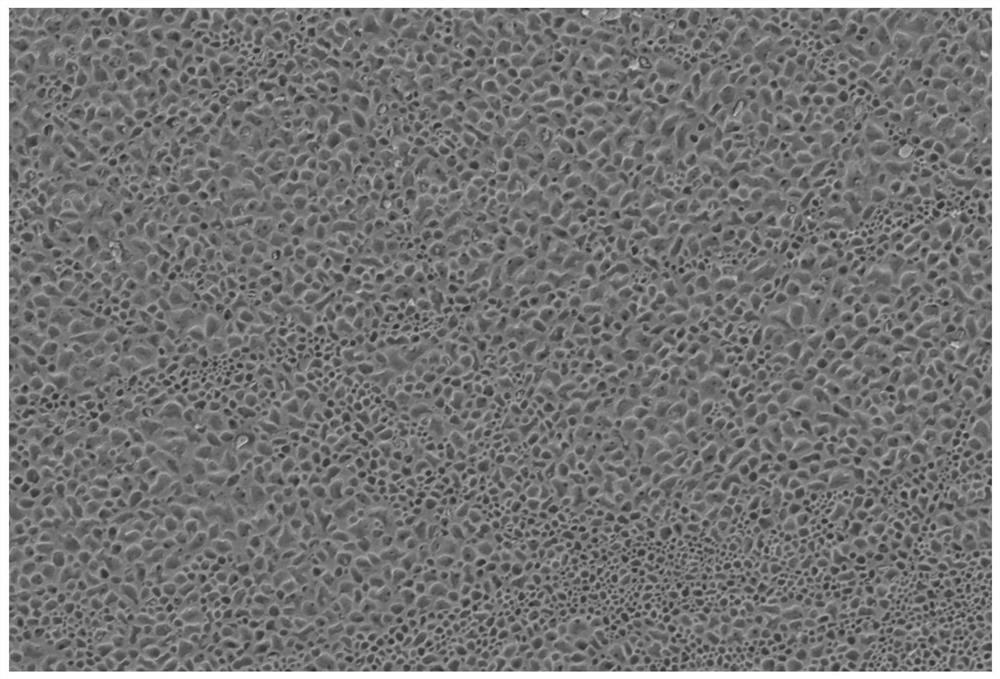

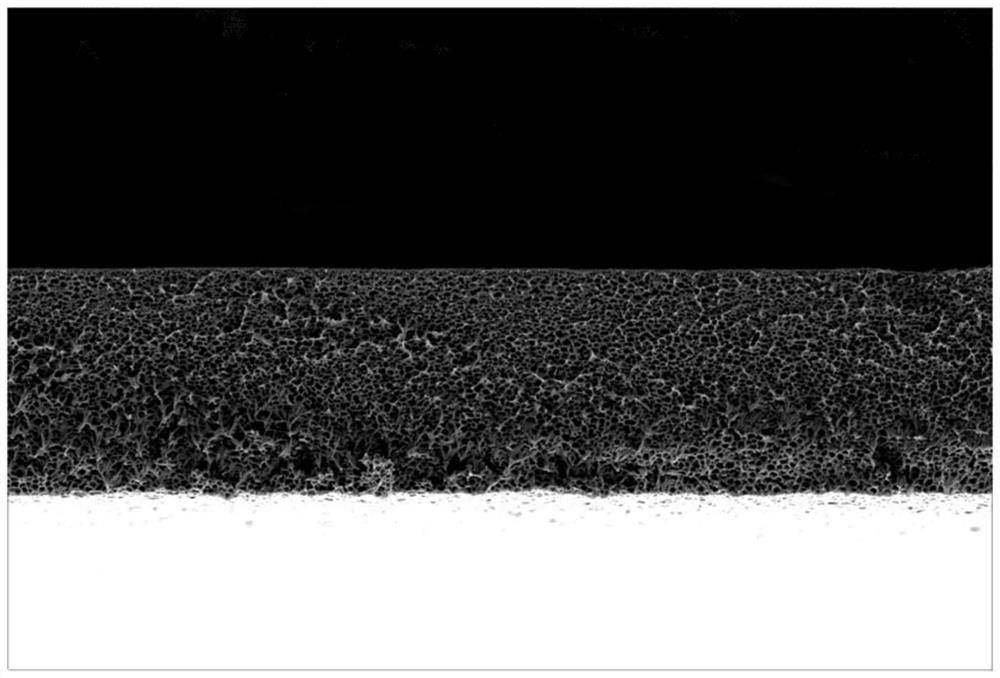

[0053] The present embodiment provides a kind of preparation method of hydrophilic polymer membrane, comprises the following steps:

[0054] 1) Dissolve the mixture of PBT and PEG1000 in the organic solvent HFIP, and stir at 50°C for 5 hours to obtain a uniform transparent casting solution; let the casting solution stand for 12 hours to remove the bubbles in the casting solution;

[0055] In parts by weight, in the casting solution, PBT and PEG1000 account for 15 parts, HFIP accounts for 85 parts, and the mass ratio of PBT and PEG1000 is 7:3;

[0056] 2) Pour the casting solution obtained in step 1) onto a glass plate, and scrape the film at a constant speed with a film scraper with a thickness of 200 μm to obtain a wet polymer film;

[0057] 3) Put the glass plate formed with the wet polymer film into the coagulation bath, phase inversion occurs, and after solidification for 1min, a nascent film is formed; in parts by weight, deionized water accounts for 70 parts in the coagu...

Embodiment 2

[0064] The present embodiment provides a kind of preparation method of hydrophilic polymer membrane, comprises the following steps:

[0065] 1) Dissolve the mixture of PBT and PEG1000 in the organic solvent HFIP, and stir at 50°C for 5 hours to obtain a uniform transparent casting solution; let the casting solution stand for 12 hours to remove the bubbles in the casting solution;

[0066] In parts by weight, in the casting solution, PBT and PEG1000 account for 15 parts, HFIP accounts for 85 parts, and the mass ratio of PBT and PEG1000 is 7:3;

[0067] 2) Pour the casting solution obtained in step 1) onto a glass plate, and scrape the film at a constant speed with a film scraper with a thickness of 200 μm to obtain a wet polymer film;

[0068] 3) put the glass plate formed with the wet state polymer film into the coagulation bath, phase inversion occurs, and after solidification for 1min, a nascent film is formed; in parts by weight, in the coagulation bath, deionized water acc...

Embodiment 3

[0072] The present embodiment provides a kind of preparation method of hydrophilic polymer membrane, comprises the following steps:

[0073] 1) Dissolve the mixture of PBT and PEG1000 in the organic solvent HFIP, and stir at 50°C for 5 hours to obtain a uniform transparent casting solution; let the casting solution stand for 12 hours to remove the bubbles in the casting solution;

[0074] In parts by weight, in the casting solution, PBT and PEG1000 account for 15 parts, HFIP accounts for 85 parts, and the mass ratio of PBT and PEG1000 is 7:3;

[0075] 2) Pour the casting solution obtained in step 1) onto a glass plate, and scrape the film at a constant speed with a film scraper with a thickness of 200 μm to obtain a wet polymer film;

[0076] 3) Put the glass plate formed with the wet state polymer film into the coagulation bath, phase inversion occurs, and after solidification for 1min, a primary film is formed; in parts by weight, in the coagulation bath, PEG400 accounts for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com