Preparation method of nascent state in-situ modified reverse osmosis membrane

An in-situ modification and reverse osmosis membrane technology, which is applied in reverse osmosis, semipermeable membrane separation, chemical instruments and methods, etc., can solve problems such as easy shedding of nanoparticles, difficulty in research and development of new monomers, and secondary pollution of the environment. The effect of reducing defects, enhancing selective permeability, and increasing flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

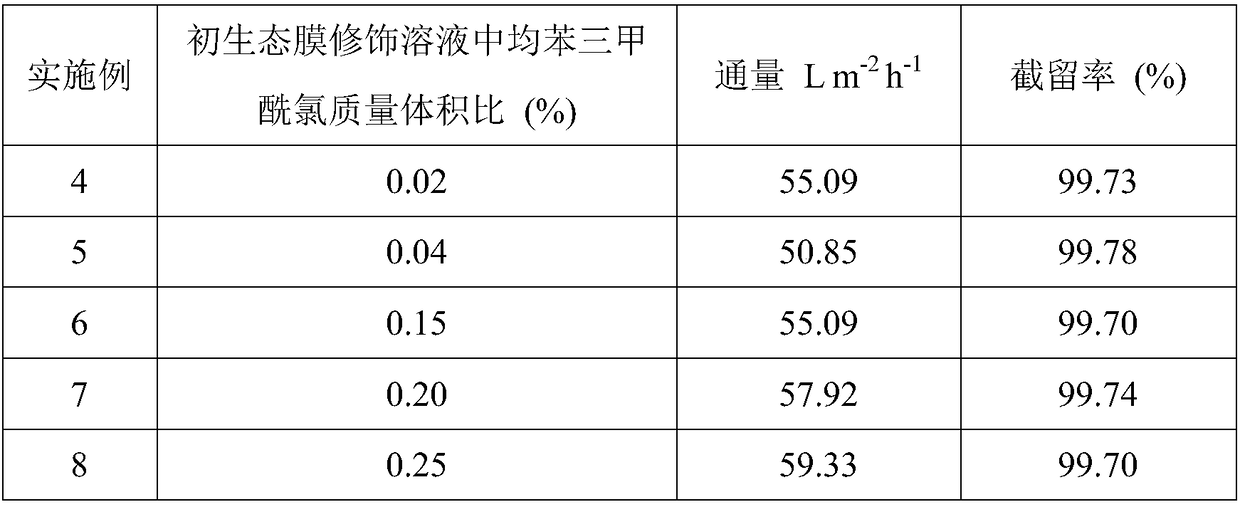

Examples

Embodiment 1

[0021] Trimelliticoyl chloride is added into n-hexane, stirred and dissolved to form a uniform transparent organic phase, and the mass volume fractions are 0.1% and 0.01%. The m-phenylenediamine was dissolved to prepare an aqueous solution with a mass volume fraction of 2.0% (triethylamine and camphorsulfonic acid adjusted to pH=10, wherein the mass volume fraction of camphorsulfonic acid was 4.0%). Pour the aqueous phase solution on the polysulfone support membrane, let it stand for 5 minutes, then remove the excess aqueous phase, drain until there is no visible water stain on the surface of the membrane, and then pour the organic phase containing 0.1% trimesoyl chloride to react for 30s , then pour out the organic phase to form a nascent reverse osmosis membrane, then pour into the organic phase solution containing 0.01% trimesoyl chloride to modify the reaction in situ for 30s, then pour out the organic phase, and finally put it into an oven to dry to form a film (heat treat...

Embodiment 2

[0024] Add trimesoyl chloride into cyclohexane, stir and dissolve to form a uniform transparent organic phase, with a mass volume ratio of 0.1%. The m-phenylenediamine was dissolved to prepare an aqueous solution with a mass volume fraction of 2.0% (triethylamine and camphorsulfonic acid adjusted to pH=10, wherein the mass volume fraction of camphorsulfonic acid was 4.0%). Pour the aqueous phase solution on the polysulfone support membrane, let it stand for 5 minutes, then remove the excess aqueous phase solution, drain until there is no visible water stain on the surface of the membrane, and then pour into the organic phase containing 0.1% trimesoyl chloride for reaction 30s, then pour out the organic phase to form a nascent reverse osmosis membrane, then pour into the organic phase cyclohexane solution without trimesoyl chloride for in-situ modification reaction for 30s, then pour out the organic phase, and then put it in an oven and dry it into Film (heat treatment temperat...

Embodiment 3

[0027] Without nascent membrane modification, the rest of the operating steps are the same as in Example 1. Under the pressure of 1.55MPa, the permeation flux of the membrane is 45.32(L m -2 h -1 ), the retention rate to sodium chloride is 99.77%. Under the pressure of 5.5MPa, the permeation flux of the membrane is 69.22(Lm -2 h -1 ), the retention rate to sodium chloride is 99.03%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com