Machining process of large welding gear

A technology of welding gear and processing technology, which is applied in the field of gears, can solve the problems of unfavorable large-scale welding gears, short stable working time of welding gears, and short service life of gears, etc., and achieve lively overall performance, convenient operation, and improved hardness and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

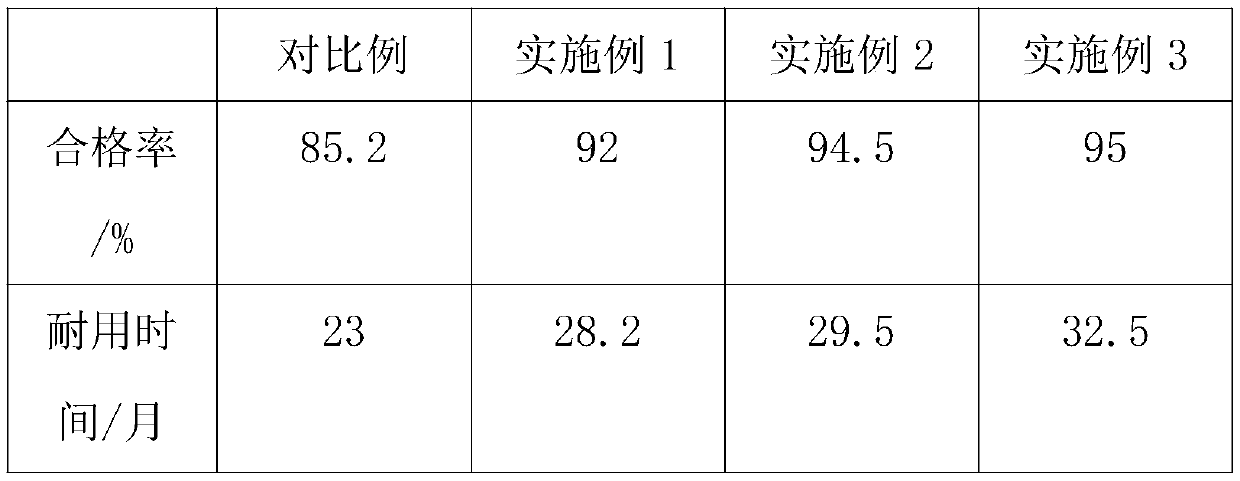

Embodiment 1

[0031] Step 1: Preliminary machining of the gear blank: clamp the blank of the gear on a vertical turning machine, install an auxiliary stabilizing device on the other side of the main shaft, and then check the precision of the inner hole and end surface of the gear blank by machining equipment preliminary processing;

[0032] Step 2: Blank preparatory heat treatment: carbon steel and alloy steel with a carbon content of 0.5% are annealed, that is, the metal is slowly heated to a specified temperature, and the steel is heated to 30 degrees Celsius above the critical temperature, kept for 30 minutes, and then heated with the furnace cool down;

[0033] Step 3: Preliminary machining of gear tooth profile: Secondary machining of the inner hole and end face of the heat-treated gear;

[0034] Step 4: Turning of the gear tooth shape: Fix the above-mentioned gear blank with a CNC machine tool, and process the inner hole and end face of the gear blank through the CNC machine tool;

...

Embodiment 2

[0040] Step 1: Preliminary machining of the gear blank: clamp the blank of the gear on a vertical turning machine, install an auxiliary stabilizing device on the other side of the main shaft, and then check the precision of the inner hole and end surface of the gear blank by machining equipment preliminary processing;

[0041] Step 2: Blank preparatory heat treatment: carbon steel and alloy steel with a carbon content of 1% are annealed, that is, the metal is slowly heated to a specified temperature, and the steel is heated to 40 degrees Celsius above the critical temperature, kept for 40 minutes, and then heated with the furnace cool down;

[0042] Step 3: Preliminary machining of gear tooth profile: Secondary machining of the inner hole and end face of the heat-treated gear;

[0043]Step 4: Turning of the gear tooth shape: Fix the above-mentioned gear blank with a CNC machine tool, and process the inner hole and end face of the gear blank through the CNC machine tool;

[0...

Embodiment 3

[0049] Step 1: Preliminary machining of the gear blank: clamp the blank of the gear on a vertical turning machine, install an auxiliary stabilizing device on the other side of the main shaft, and then check the precision of the inner hole and end surface of the gear blank by machining equipment preliminary processing;

[0050] Step 2: Blank preparatory heat treatment: carbon steel and alloy steel with a carbon content of 1.5% are annealed, that is, the metal is slowly heated to a specified temperature, and the steel is heated to 50 degrees Celsius above the critical temperature, kept for 50 minutes, and then heated with the furnace cool down;

[0051] Step 3: Preliminary machining of gear tooth profile: Secondary machining of the inner hole and end face of the heat-treated gear;

[0052] Step 4: Turning of the gear tooth shape: Fix the above-mentioned gear blank with a CNC machine tool, and process the inner hole and end face of the gear blank through the CNC machine tool;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com