A kind of fast composting method and application of biogas residue

A composting method and biogas residue technology, which are applied in the application, fertilization device, organic fertilizer and other directions, can solve the problems such as the rapid utilization of biogas residues by microorganisms, unfavorable sustainable utilization of biogas residues, and increase in the cost of biogas residue treatment, so as to achieve human health. And the effect of increasing the added value of agricultural products, low cost and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]Method for fast composting of biogas residue

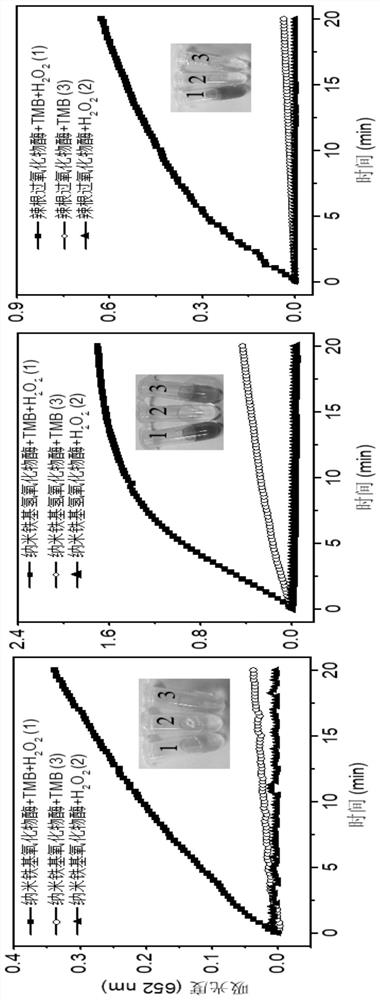

[0028](1) Synthesis of nano-iron-based hydroxide enzyme: Stir to 0.5mol / L ferric chloride hexahydrate solution and slowly add 1mol / L sodium hydroxide solution, adjust the pH to 7.0, the solution is suspended at room temperature Let stand for 4 hours to fully precipitate the iron-based hydroxide suspension; centrifuge the iron-based hydroxide suspension at 4℃ and 8000r / min for 30min, then rinse the precipitate with deionized water and centrifuge again , Repeatedly washing the precipitate and centrifuging 8 times, until the chloride ion concentration in the iron-based hydroxide suspension is less than 1mmol / L, to obtain a synthetic nano-iron-based hydroxide enzyme with an average particle size of 7nm for use;

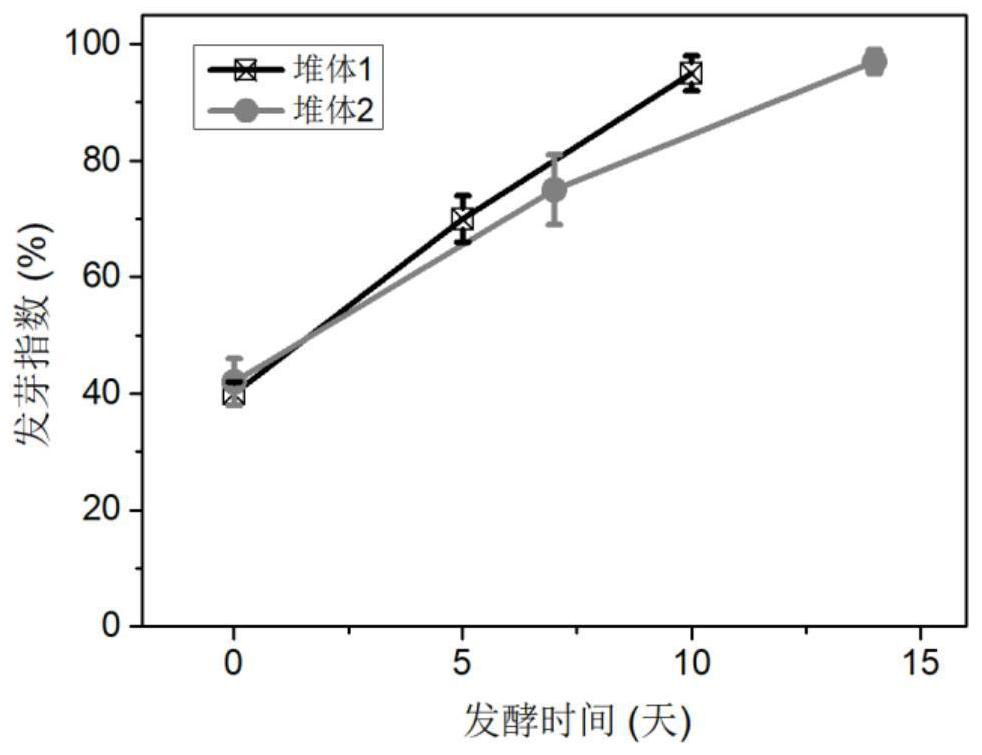

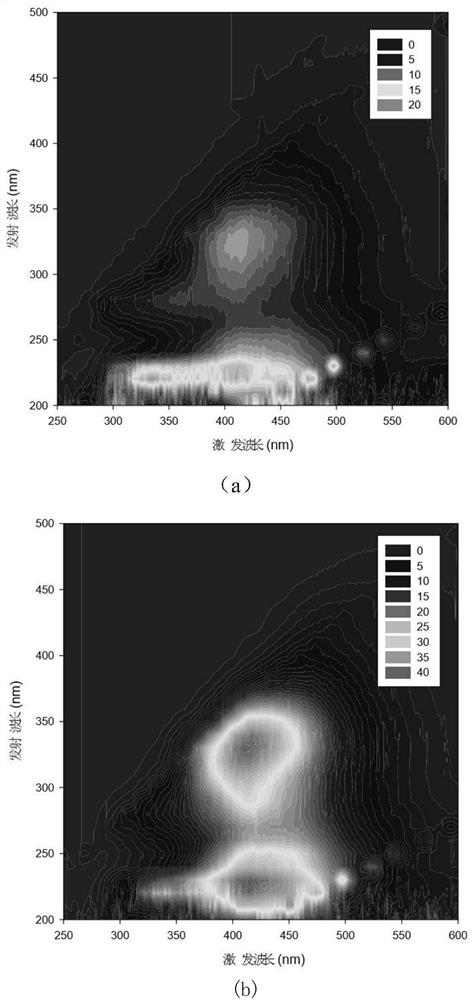

[0029](2) Compost maturity: Add the use amount of 0.01‰ of the biogas residue weight ratio and the average particle size of 7nm nano iron-based hydroxide enzyme into the biogas residue with a carbon to nitrogen ratio of 25:1, and a...

Embodiment 2

[0031]Method for fast composting of biogas residue

[0032](1) Synthesis of nano-iron-based oxidase: Stir in 0.5mol / L ferric chloride hexahydrate solution and slowly add 1mol / L sodium hydroxide solution, adjust the pH to 7.0, the solution is in a suspended state and stay at room temperature Leave for 4 hours to fully precipitate the iron-based hydroxide suspension; centrifuge the iron-based hydroxide suspension at 4°C and 8000r / min for 30 minutes, then rinse the precipitate with deionized water and centrifuge again. The precipitate was washed repeatedly and centrifuged 8 times until the chloride ion concentration in the iron-based hydroxide suspension was less than 1mmol / L to obtain synthetic nano-iron-based hydroxide enzyme; then the synthesized nano-iron-based hydroxide enzyme was heated at 98°C Aging for 7 days under high temperature conditions to obtain nano-iron-based oxidase with an average particle size of 20nm for use;

[0033](2) Compost maturity: Add the use amount of 0.1‰ of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com