Water-boiled-type environment-friendly surface printing polyamide white ink and preparation method thereof

A surface printing technology of polyamide and white ink, which is applied in the field of plastic surface printing printing ink, can solve the problems of not being resistant to temperature and boiling, high friction coefficient, slow printing machine speed, etc., to achieve smooth surface, small friction coefficient, Excellent printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

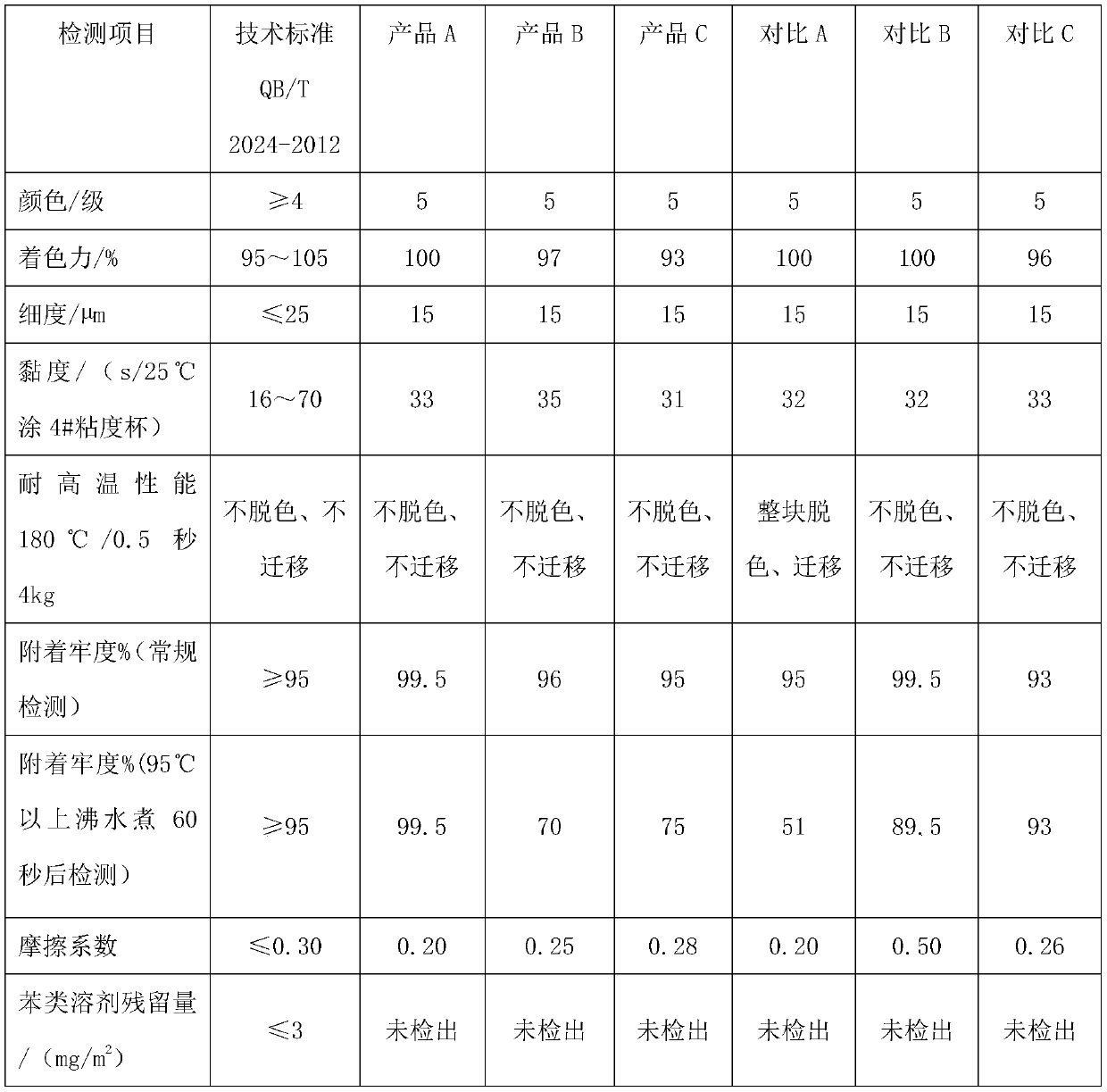

Examples

Embodiment 1

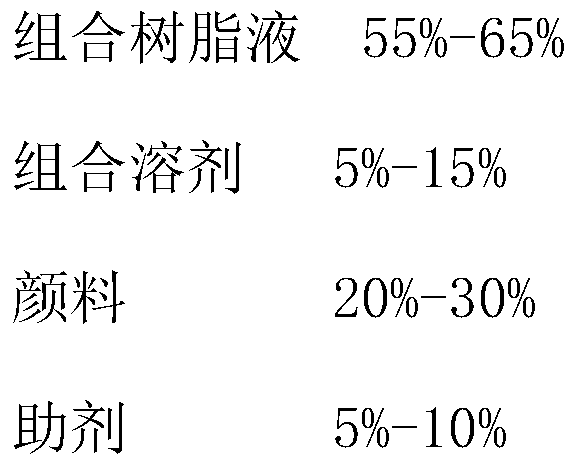

[0042] A kind of polyamide white ink that is used for boiling type environment-friendly surface printing, is made up of the raw material of following weight part:

[0043]30 parts of polyamide resin solution, 20 parts of nitrocellulose resin solution, 3 parts of rosin modified maleic acid resin solution, 3 parts of polyketone resin solution, 4 parts of EVA resin solution, 25 parts of rutile titanium dioxide, 0.8 part of erucamide , 1.0 parts of fumed silica, 0.6 parts of anionic surfactant, 1.8 parts of crosslinking agent, 2 parts of absolute ethanol, 3.8 parts of ethyl acetate, 5 parts of butyl acetate;

[0044] The preparation method is:

[0045] (1) Polyamide resin liquid: take 40 parts by weight of polyamide, dissolve in 30 parts of absolute ethanol and 30 parts of ethyl acetate to emulsify and disperse in the mixed solvent that forms, and make the polyamide resin liquid that mass percent concentration is 40% ;

[0046] (2) Nitrocellulose resin liquid: take 35 parts by w...

Embodiment 2

[0052] A kind of polyamide white ink that is used for boiling type environment-friendly surface printing, is made up of the raw material of following percentage by weight:

[0053] 25 parts of polyamide resin solution, 25 parts of nitrocellulose resin solution, 3 parts of rosin modified maleic acid resin solution, 3.8 parts of polyketone resin solution, 4 parts of EVA resin solution, 25 parts of rutile titanium dioxide, 0.8 part of erucamide , 1.0 parts of fumed silica, 0.6 parts of anionic surfactant, 1.0 parts of crosslinking agent, 2 parts of ethanol, 3.8 parts of ethyl acetate, 5.0 parts of butyl acetate;

[0054] The preparation method of its resin liquid and product is identical with embodiment 1, and the product of gained is " product B ".

Embodiment 3

[0056] A kind of polyamide white ink that is used for boiling type environment-friendly surface printing, is made up of the raw material of following percentage by weight:

[0057] 25 parts of polyamide resin solution, 25 parts of nitrocellulose resin solution, 5 parts of rosin modified maleic acid resin solution, 4 parts of polyketone resin solution, 4 parts of EVA resin solution, 22 parts of rutile titanium dioxide, 1.0 parts of erucamide , 1.0 parts of fumed silica, 0.9 parts of anionic surfactant, 1.3 parts of crosslinking agent, 2 parts of ethanol, 3.8 parts of ethyl acetate, 5 parts of butyl acetate;

[0058] Its resin liquid and product preparation method are identical with embodiment 1, and the product of gained is " product C ".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com