Production method of super-hydrophobic film

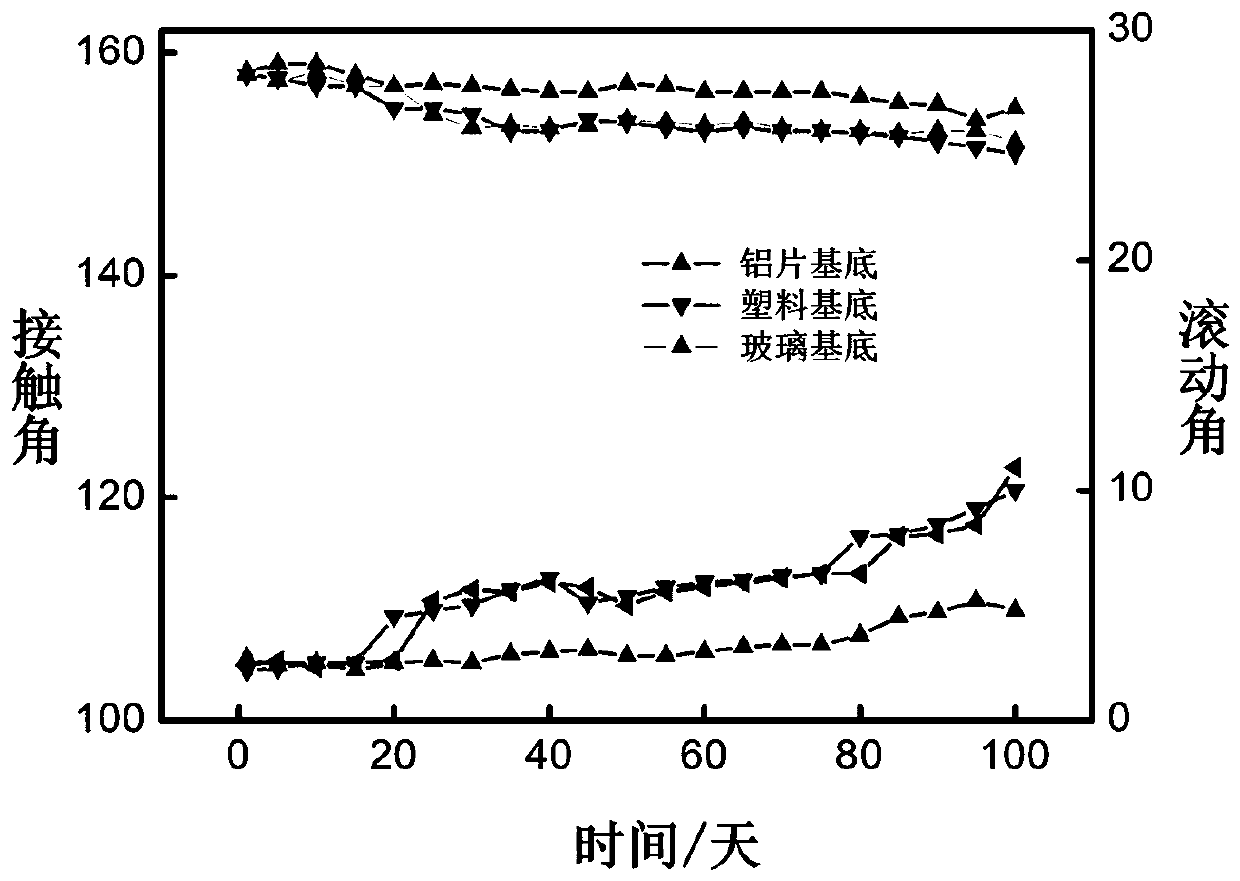

A hydrophobic film and super-hydrophobic technology, which is applied in the direction of surface coating liquid devices, coatings, special surfaces, etc., can solve the problems of not achieving the desired effect, single protection function, high maintenance cost, etc., and achieve good anti-corrosion Anti-icing performance, preventing surface icing, and prolonging the effect of icing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of silicon dioxide and PVDF hydrophobic film and its preparation method, comprising the following materials: 10ml of DMF solution, 0.5g of PVDF powder, 0.7g of silica particles, 1ml of hydrophobic modification liquid.

[0024] The preparation of the hydrophobic film at room temperature includes the following steps:

[0025] (1) Preparation of silicon dioxide and PVDF film: add 0.7g of hydrophobic silicon dioxide particles to 0.5g of PVDF solution, fully stir for a period of time to obtain its mixed solution;

[0026] (2) Preparation of PVDF solution: add 10ml of DMF to the weighing bottle, and then add 0.5g of PVDF to the weighing bottle, and stir at room temperature for 6 hours until the whole solution becomes clear.

[0027] (3) Stir the obtained PVDF solution with 0.7 g of hydrophobic silica particles for 3 hours to obtain a silica and PVDF mixed coating;

[0028] (4) Preparation of hydrophobic modification solution: mix hexadecyltrimethoxysilane and absol...

Embodiment 2

[0036] A preparation method of silicon dioxide and PVDF hydrophobic film and its preparation method, comprising the following substances: 10ml of DMF solution, 0.5g of PVDF powder, 0.5g of silica particles, 1.5ml of hydrophobic modification solution.

[0037] The preparation of the hydrophobic film at room temperature includes the following steps:

[0038] (1) Preparation of silica and PVDF film: add 0.5 g of hydrophobic silica particles to 0.5 g of PVDF solution, and stir for a period of time to obtain the mixed solution;

[0039] (2) Preparation of PVDF solution: add 10ml of DMF to the weighing bottle, and then add 0.5g of PVDF to the weighing bottle, and stir at room temperature for 6 hours until the whole solution becomes clear.

[0040] (3) Stir the obtained PVDF solution with 0.5 g of hydrophobic silica particles for 3 hours to obtain a silica and PVDF mixed coating;

[0041] (4) Preparation of hydrophobic modification solution: mix hexadecyltrimethoxysilane and anhydrous ethanol ...

Embodiment 3

[0046] The product obtained in Example 2 was subjected to different pH detection steps.

[0047] (1) Dilute concentrated hydrochloric acid in a certain amount of water into solutions with pH=1, pH=2, pH=3, pH=4, pH=5, and pH=6; prepare 3.5wt% sodium chloride solution as Solution with pH=7; Dissolve a certain amount of sodium hydroxide in water to prepare solutions with pH=8, pH=9, pH=10, pH=11, and pH=12.

[0048] (2) The product in Example 2 was immersed in the solution prepared in step (1), and the contact angle was measured after 24h and 120h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com