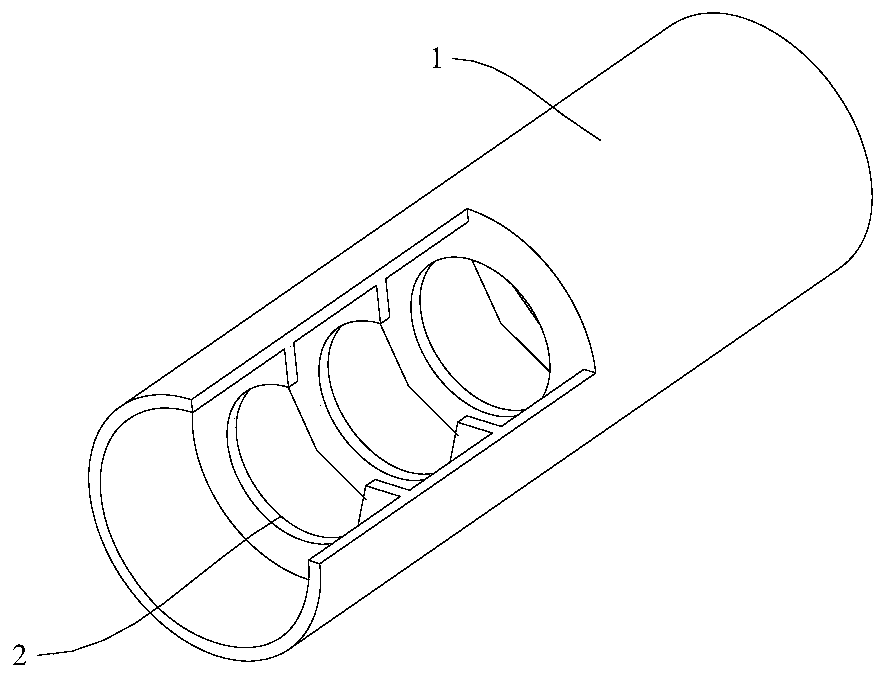

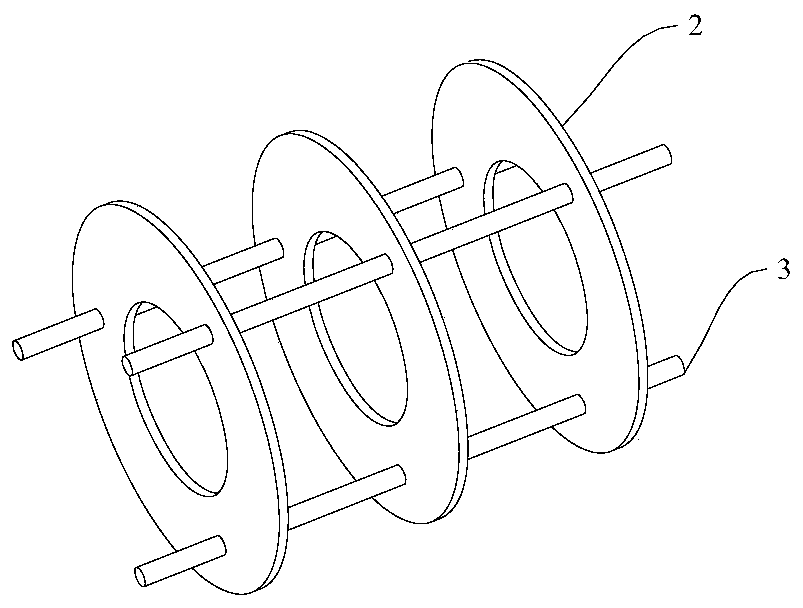

Heat exchange tube of waste heat boiler

A waste heat boiler and heat exchange tube technology, applied in boiler water tubes, boiler smoke tubes/fire tubes, steam boilers, etc., can solve problems such as limiting the use range of heat exchange tubes and unstable fluoroplastic films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

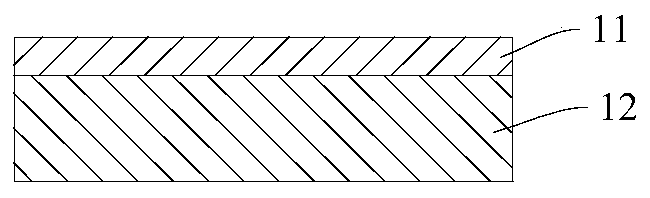

[0040] The nano-alumina anti-corrosion coating 3 includes the following five ingredients: nano-alumina, calcium aluminate, calcium phosphate, nano-aluminum powder and nano-alumina sol; the average particle size of the nano-alumina is 20nm, and the purity is ≥99.9%; The average particle size of the nano-aluminum powder is 50nm; the average particle size of the nano-alumina sol is 10-15nm, the solid content is 25%, and the pH value is 4; the purity of the calcium aluminate and calcium phosphate is ≥99%. Raw materials were obtained commercially.

[0041]The nano-alumina anti-corrosion coating consists of the following ingredients in parts by mass: 50 parts of nano-alumina, 5 parts of calcium aluminate, 5 parts of calcium phosphate, and 20 parts of nano-aluminum powder. Add 20 parts of nano-alumina sol to the coating ingredients mixed in proportion, and grind in a ball mill for 2 hours to obtain a homogeneous phase mixture. The homogeneous phase mixture is sprayed on the outer su...

Embodiment 2

[0044] The nano-alumina anti-corrosion coating 3 includes the following five ingredients: nano-alumina, calcium aluminate, calcium phosphate, nano-aluminum powder and nano-alumina sol; the average particle size of the nano-alumina is 20nm, and the purity is ≥99.9%; The average particle size of the nano-aluminum powder is 50nm; the particle size of the nano-alumina sol is 10-15nm, the solid content is 25%, and the pH value is 4; the purity of the calcium aluminate and calcium phosphate is ≥99%.

[0045] The nano-alumina anti-corrosion coating consists of the following ingredients in parts by mass: 40 parts of nano-alumina, 10 parts of calcium aluminate, 10 parts of calcium phosphate, and 30 parts of nano-aluminum powder. Add 10 parts of nano-alumina sol to the coating ingredients mixed in proportion, and grind in a ball mill for 2 hours to obtain a homogeneous phase mixture. The homogeneous phase mixture is sprayed on the outer surface of the heat exchange tube 1 that has been ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com