Strong grinding coated abrasive tool preparation method and strong grinding coated abrasive tool prepared through strong grinding coated abrasive tool preparation method

A grinding-coated, strong technology, applied in abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems of easy falling off of abrasives and easy deformation of abrasives with strong grinding and coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of a strong grinding coated abrasive provided by the present invention includes raw cloth treatment, large roll manufacturing and large roll post-processing. The raw fabric treatment includes a shaving and singeing step, a desizing and degreasing step, a dyeing and dipping step, a stretching step, a reinforcing coating step and a calendering step. The production of large rolls includes the steps of printing trademarks, applying primer, sanding, pre-drying, gluing and main drying. Optionally, jumbo post-processing includes a post-curing step, a storage step, a humidification step, a flexing step, and a converting step.

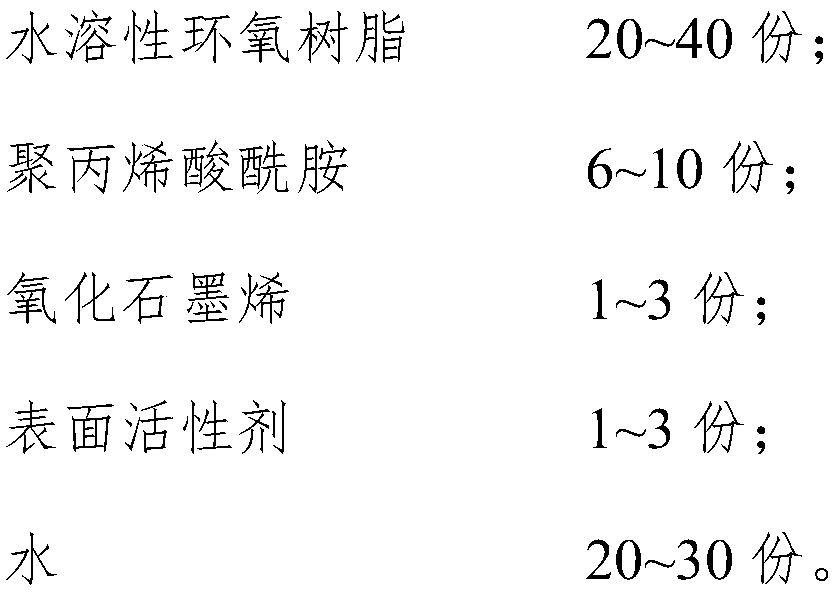

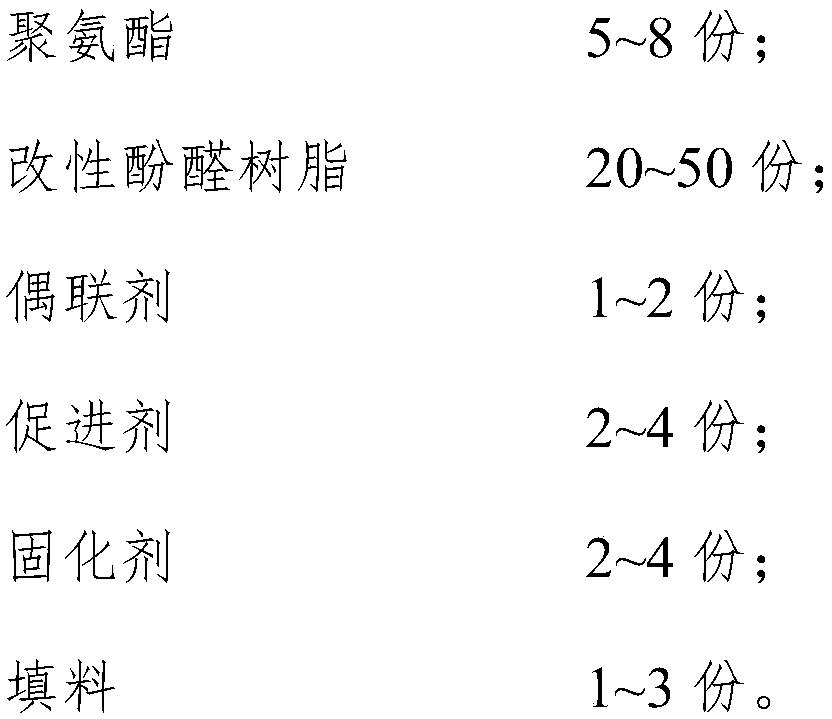

[0023] Wherein, the strengthening coating step is to coat the reinforcing agent on the surface of the original cloth after the stretching step. The impregnating solution in the dyeing and impregnating step contains water-soluble epoxy resin. The reinforcing agent comprises the following raw materials in parts by weight:

[0024]...

Embodiment 1

[0042] Put 2kg of graphene oxide and 2kg of surfactant into 25kg of water for ultrasonic dispersion, then add 30kg of water-soluble epoxy resin and 8kg of polyacrylamide and stir at 1400r / min for 2 to 4 hours to prepare the reinforcing agent.

[0043] Take 50kg of water-soluble epoxy resin, add 1.5kg of coupling agent, 3kg of accelerator, 3kg of curing agent, and 2kg of filler in several times under the stirring condition of 1500r / min and stir evenly, then add 6.5kg of polyurethane and 35kg of modified phenolic resin Stir at 1500r / min for 1-2h to prepare the adhesive.

[0044] Raw fabric treatment: take the raw polyester cloth and go through shaving, singeing, desizing and degreasing, dyeing and dipping, and stretching in sequence, and then coat the above-mentioned strengthening agent with a thickness of 3 μm on both sides of the raw fabric, and then perform calendering treatment.

[0045] Manufacturing in large rolls, printing the trademark on one side of the original fabric,...

Embodiment 2

[0047] Put 1kg of graphene oxide and 1kg of surfactant into 20kg of water for ultrasonic dispersion, then add 20kg of water-soluble epoxy resin and 6kg of polyacrylamide and stir at 1500r / min for 2-4 hours to prepare the reinforcing agent.

[0048] Take 40kg of water-soluble epoxy resin, add 1kg of coupling agent, 2kg of accelerator, 2kg of curing agent, and 1kg of filler in several times under the stirring condition of 1500r / min and stir evenly, then add 5kg of polyurethane and 20kg of modified phenolic resin at 1500r / min / min and stir for 1-2 hours to prepare the adhesive.

[0049] Raw fabric treatment: Take the raw polyester cloth and go through shaving and singeing, desizing and degreasing, dyeing and dipping, and stretching in sequence, and then coat the above-mentioned strengthening agent with a thickness of 2 μm on one side of the raw fabric, and then perform calendering treatment.

[0050] Manufacturing in large rolls, printing the trademark on one side of the original...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com